How the 5Whys strategy supports quality management

5Whys is a beneficial problem-solving tool in quality management. It assists manufacturers in root cause analysis as part of nonconformance management and continuous process improvement efforts.

While the five whys strategy was first employed in the automotive industry, it is now used by manufacturers in a broad range of industries. 5Whys was first conceived by the founder of Toyota Industries in the 1930s – long before the computerization of the third industrial revolution, much less the full digitalization of Industry 4.0. Yet today, 5Whys has evolved into a powerful tool within a digital manufacturing ecosystem, capable of advancing quality throughout the production process. 5Whys is supported by quality management systems (QMS) and is often used in conjunction with other quality tools within QMS software.

Here are some ideas on how your manufacturing operation will benefit from 5Whys.

5Whys in context of a systematic approach

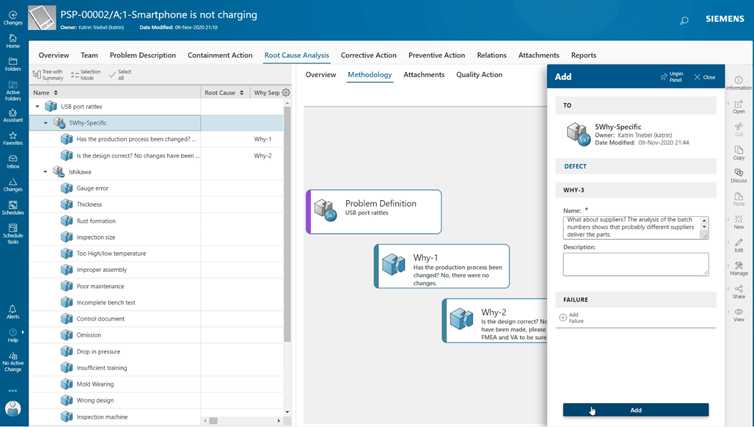

To get the most out of a 5Whys root cause analysis, a manufacturer will want to implement a structured approach to problem-solving, such as the “eight disciplines,” a problem-solving method created by the Ford Motor Company and now widely employed across the manufacturing world. In fact, many manufacturers closely associate 5Whys with the 8D report, which compiles the results of the eight disciplines’ step-by-step process. In this process, a problem-solving team is formed and commissioned to investigate the underlying causes of a manufacturing issue and to develop a plan to address the problem so that it does not recur.

In the 8D procedures 5Whys corresponds to the fourth discipline:

D1. Establish the problem-solving team

D2. Describe the problem

D3. Implement and verify interim containment actions

D4. Perform root cause analysis

D5. Select and verify the effectiveness of corrective actions

D6. Implement permanent corrective actions and standardize processes

D7. Prevent problem recurrence

D8. Conduct final discussion and review

How 5Whys root cause analysis works

The simplest description of the 5Whys approach is that a problem-solving team asks the question “Why?” five times. The sequence of why questions begins with a statement of the problem. As an example, consider the problem statement, “The bond between components A and B failed.”

Why? The bonding agent failed to adhere adequately to the joining surfaces.

Why? The bonding agent did not meet the specified bond strength requirement.

Why? The mixer combined the agent’s two parts in the wrong ratio.

Why? The mixer was not properly calibrated.

Why? The mixer calibration schedule was overlooked.

For each root cause analysis, the 5Whys process may require fewer or more whys. In the example above, one additional why may explain how the calibration schedule could be overlooked (perhaps it is a paper-based process), which suggests a problem resolution (digitalize the equipment calibration schedule, including automatic alerts).

Once the problem-solving team believes it has arrived at the initial cause, the 5Whys root cause analysis continues with a discussion of the results.

Extending Root Cause analysis

In addition to 8D reporting, a modern QMS will use the results of the root cause analysis in conjunction with several other quality tools. These tools include:

Complaint Management – Complaint management capabilities not only enable the timely handling of quality issues, but also feed product-in-use data back to production planning and process engineering. Non conformances and defects identified can be subjected to 5Whys root cause analysis, generating opportunities for continuous process improvement.

Failure modes and effects analysis (FMEA) – FMEA is first employed to assess and manage risk before the finished product is manufactured. Once manufacturing commences and quality issues occur, the 5Whys process identifies actual risks, and the FMEA can use these as it repeats the process of analyzing the chances of failures and associated consequences, then mitigating the cause. Integration into an FMEA enables companies to realize the greatest benefit from the continuous improvement process.

Change Management Process is fundamental to avoid threats to profitability and to derive changes in the early stages of development, instead of in production stages. A change can be triggered within quality and affect the entire organization.

Restructure your complaint management processes

Siemens quality solutions give you root cause analysis methods with corrective and preventive actions in hands and the ability to monitor all quality activities centrally with the aim to reduce the total cost of quality within your company.

Teamcenter Quality and Opcenter Quality software systems support 5Whys root cause analysis as well as its beneficial interactions with other QMS functions. Through 5Whys and these other tools, our QMS customers gain a better understanding of the relationships between various materials, equipment and parameters involved in each production run, which in turn streamlines quality improvement efforts and lowers the cost of rework and scrap. Supporting a holistic quality program, Teamcenter Quality and Opcenter Quality are part of the Siemens Xcelerator portfolio of software and services.

We encourage you to explore our quality portfolio today.

_____________________________________________________________________________________

Register for this upcoming webinar! When an unexpected issue arises and can impact on your product quality, how do you approach this situation? No matter how robust your planning phase and how hard you try to evaluate all possible failures, problems and defects will occur. Reacting fast is important, but only if we deeply analyze root causes and implement measures to correct those can we expect to solve the problem and avoid reoccurrence – and even improve the quality of the product itself.

Join our webinar on May 19th and discover how a holistic closed-loop quality approach helps to boost your complaint management process and improve customer satisfaction.