Extend digital efficiencies across the supply chain – Part 2

Welcome to the second in a series of three blogs about extending digital efficiencies across the supply chain

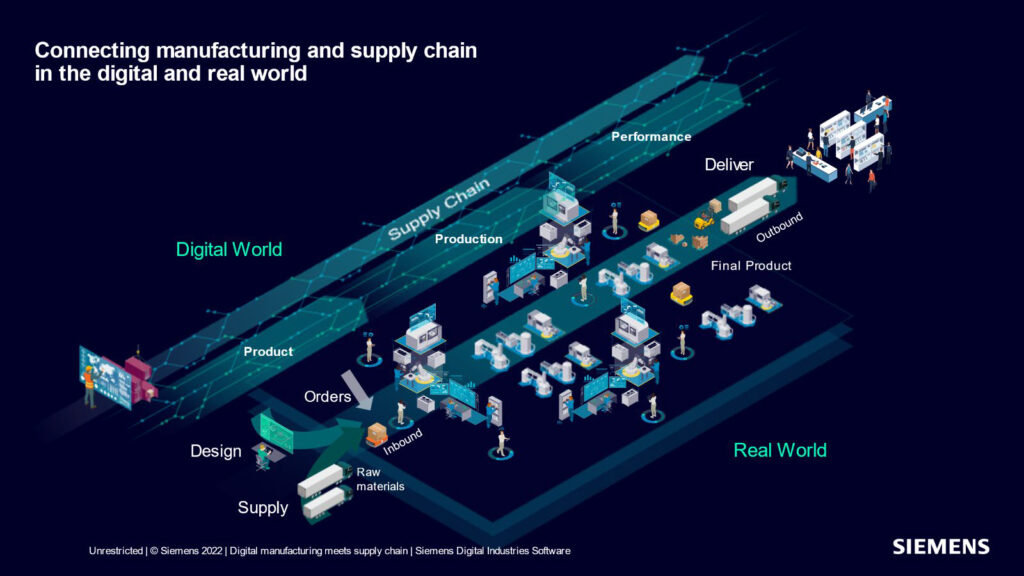

In the first post of this series, we introduced the importance of adopting an integrated digital manufacturing and supply chain solution and highlighted one of Siemens’ successful customers – Meraxis. In case you missed it give it a read here. In this second post, we explore the synergies that an integrated digital manufacturing and logistics solution generates and how it can improve visibility in the supply chain, from raw materials to finished product delivery.

Don’t miss our other posts in this series:

Extend digital efficiencies across the supply chain – Part 1

Supply chain convergence: Resilient design and execution with Siemens solutions

Gaining visibility from raw materials through delivery of the finished product

By bringing the manufacturing floor closer together with the supply chain, an integrated digital manufacturing and logistics solution can address new challenges that manufacturers face today. The integrated solution extends transparency from inbound to outbound flow, from raw material and subassemblies to delivery that satisfies an OEM’s (or higher tier’s) just-in-time/just-in-sequence (JIT/JIS) operations.

The Siemens solution connects digital logistics functions of transport planning, network optimization, transport execution, and logistics capabilities with the comprehensive digital twin supported by MOM functions of production planning and scheduling, manufacturing execution, quality management and data analytics. This integration benefits manufacturers, first, by enabling supply chain design to “shift left” and come into consideration early in the product and process design phase.

During production, this holistic approach provides each stakeholder with real-time knowledge of the status of raw, semi-finished, and finished goods. If a new order, an interruption of a manufacturing line or some other disruptive event must be accommodated by adjusting the production schedule, an integrated digital manufacturing and logistics solution makes this change visible to the logistics team, which can determine the impact on the supply chain of this manufacturing disruption. Conversely, a supply chain disruption is made visible to production schedulers and may trigger adjustments to the production schedule. In either case, companies across the supply chain benefit from lower operational costs and greater throughput.

In today’s volatile marketplace, manufacturers need to operate efficient manufacturing networks, achieve production goals, and meet customer demands even in the midst of disruptive events. With Siemens integrated digital manufacturing and logistics solution, the goal of an agile, resilient, reliable, and cost-efficient manufacturing business is in sight.

Realizing “shift left” benefits of logistics planning

The impact of supply chain convergence inside the production facility begins before the first product rolls off the production line, during product and process design. By actualizing the “shift left” concept, in which design and problem-solving activities are shifted to the left on the timeline, an integrated digital manufacturing and logistics solution allows you to start designing supply chain management (SCM) while product and process designs are still being validated and finalized. You will be able to predict potential supply chain risks and problems and resolve them before production begins.

Early collaboration among product, process, and supply chain design teams, enabled by the integrated digital solution, allows you to create a holistic manufacturing plan. Much of this planning effort can be conducted in the virtual realm, which is faster and much lower in cost than physical prototyping, validation, and commissioning. Collaboration enables early consideration of design alternatives, which allows you to gain confidence that the supply chain will be well-harmonized with production processes. Conversely, identifying potential supply chain issues early enables your designers to take SCM insights into consideration and improve the manufacturing plan.

Would you like to learn more about how Opcenter APS can give you a competitive advantage in Supply Chain convergence?

Read our eBook “Supply Chain Management Planning – challenges and Opportunities” to get more insights!

or Start your free, Opcenter APS 30-day trial in minutes ->