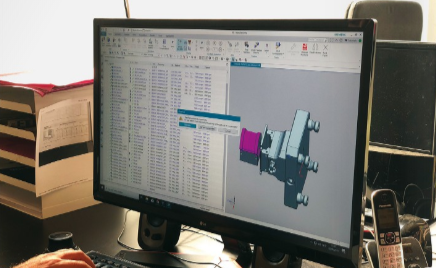

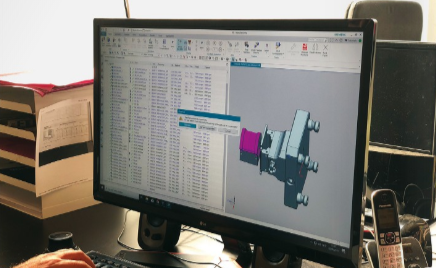

YouniQ: Reducing lead times for small machined parts

Connected Technology Solutions, a UK-based hi-tech industry magazine, recently published a case study about how Siemens customer, YouniQ Machining, has reduced time to market from the typical eight to 12 weeks of competitors to two days with the integrated CAD / CAM capabilities in NX software. In the article, “YouniQ: Reducing lead times for small machined parts,” YouniQ explains how they have realized higher margins than competitors, enabling investments in future innovations. “The company has also reduced its reliance on highly skilled experts and decreased its administrative burden, enabling the company to focus on its core machining business. With processes defined and programmed in NX, the company has standardized its development processes and enabled standardization of its production hardware.”

Read the success story on our website, or read the article, Reducing Lead Times for Small Machined Parts to learn how you can achieve similar results with NX software.

The feature-based machining capabilities of NX CAM were also critical to the digital flow. With feature-based machining, numerical control (NC) programs can be created automatically based on features in the component model. A capability called the machine knowledge editor (MKE) enabled YouniQ engineers to record all rules and tools used in machining the features to capture knowledge and data that drives the automated NC programming

You can learn more about NX CAM software by viewing our extensive product information pages.

Register now and try NX CAM free for 30 days!