What’s New in NX for Manufacturing (June 2022)

A new release of NX for Manufacturing is here! With NX 2206, you will encounter new capabilities as well as updated ones, enabling you and your company to reach new levels of productivity with NX for Manufacturing.

In this blog, you will learn about the latest features and product updates for our comprehensive software for part manufacturing, including:

- NX CAM

- NX Additive Manufacturing

- Manufacturing Process and Data Management

- NX CMM Inspection Programming

- NX Assembly Line Planner

- NX Line Designer

- NX Fixture Planner

What’s New in NX CAM

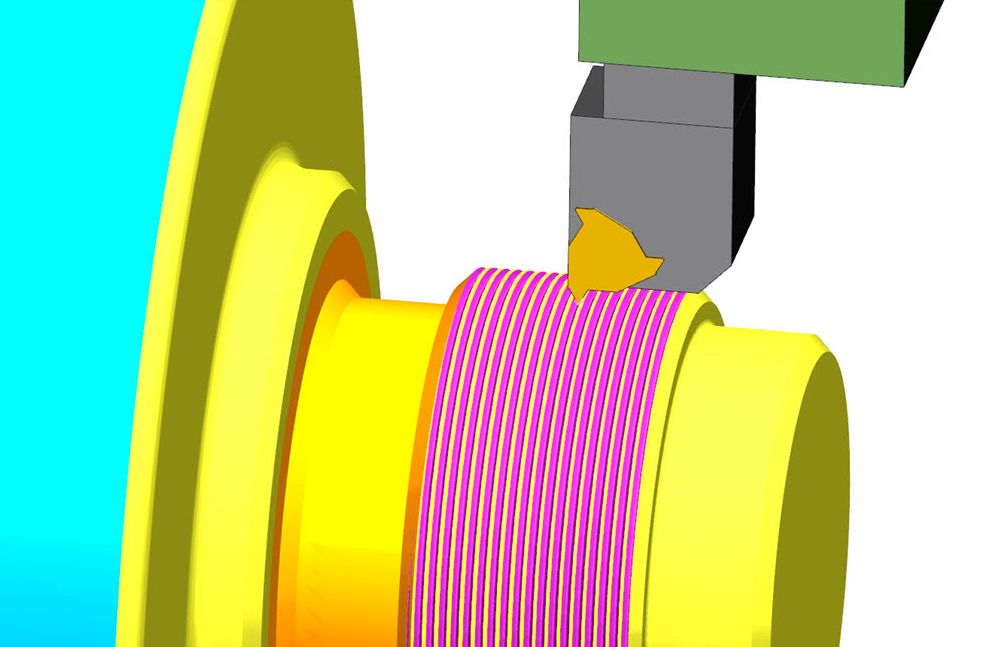

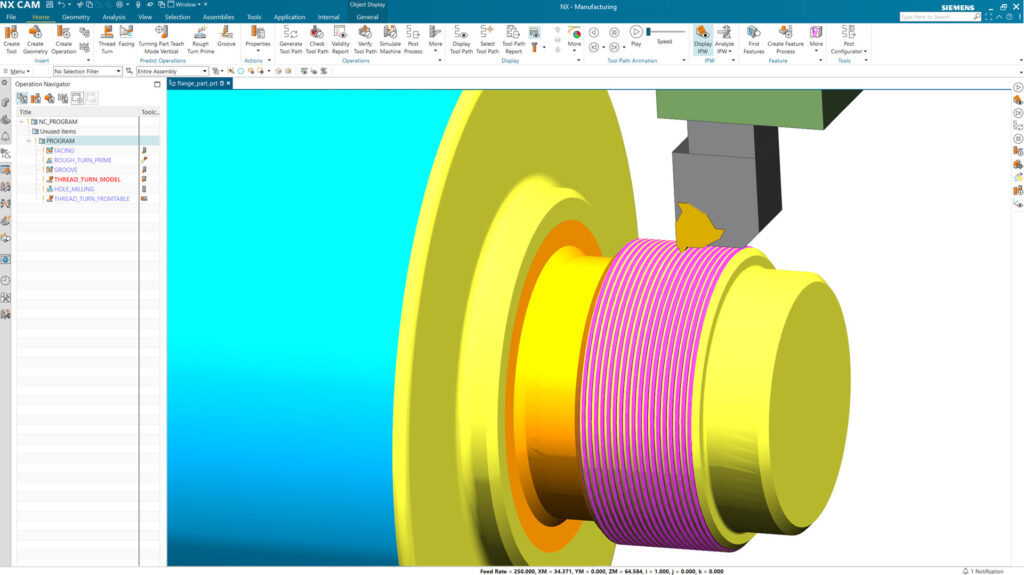

The new Thread Turning Operation automatically recognizes 3D parts’ features and creates advanced toolpaths for straight and tapered threads, while providing multiple infeed methods. The new automated methods to create CNC machining thread operations minimizes manual input, accelerating turning programming.

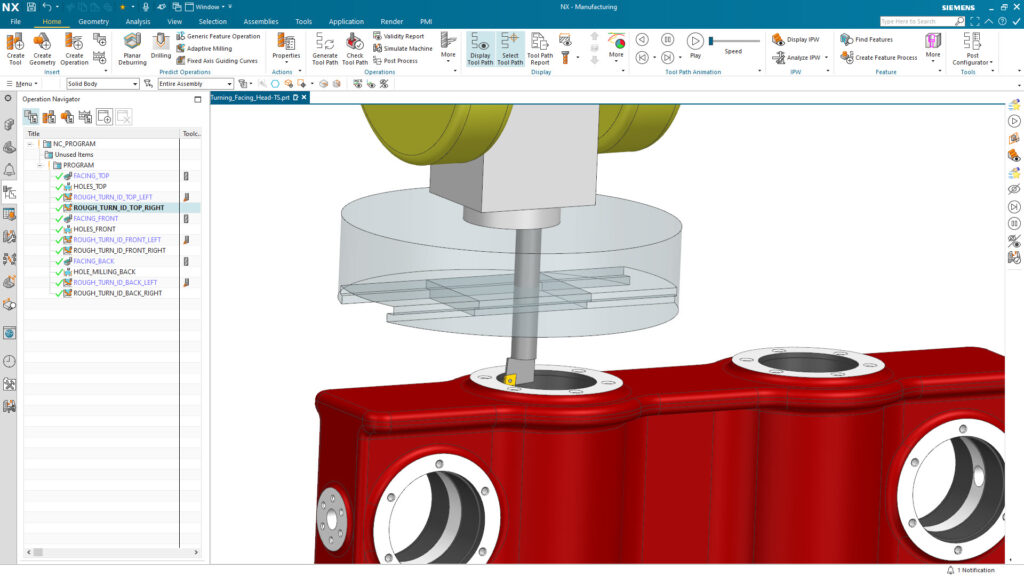

The U-Axis Turning support assists in machining parts using U-axis turning, allowing for easier programming and simulation of facing heads. U-axis turning can be programmed for multiple turning spindle axes to achieve stationary, updated In-process Workpiece (IPW) when mounted to facing heads.

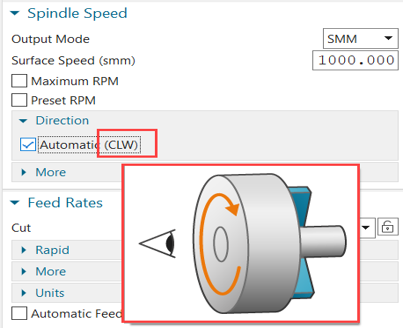

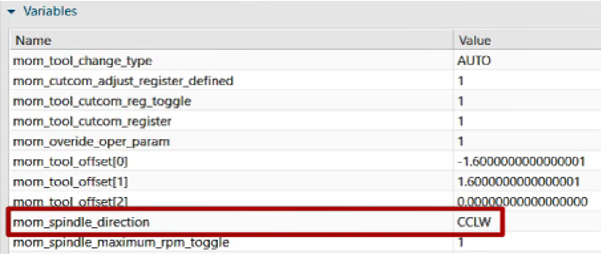

The new Reversed Spindle Direction utilizes the new definition for turning operation and postprocessor. You can now align and display spindle direction during the programming without needing to adjust the postprocessor. The new UI provides increased usability and faster programming.

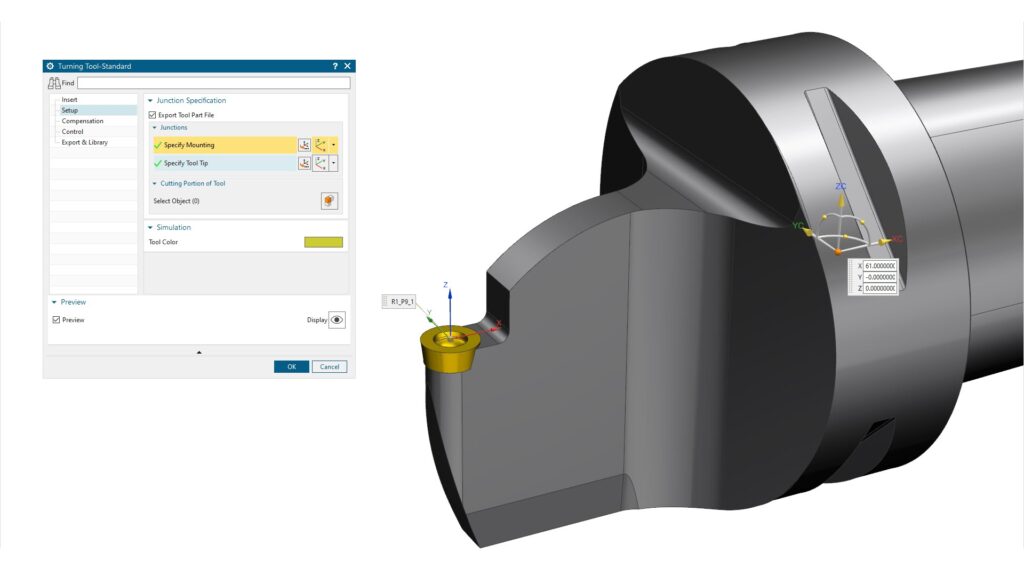

The improved user experience in Tool Creation and Turning Tool Usage simplifies the 3D assembly tool creation workflow with UI-driven, intuitive guidance in the context of the machine. The reduced manual interaction in tool definition and usage eliminates errors and possible incorrect parameterization of the cutting tool.

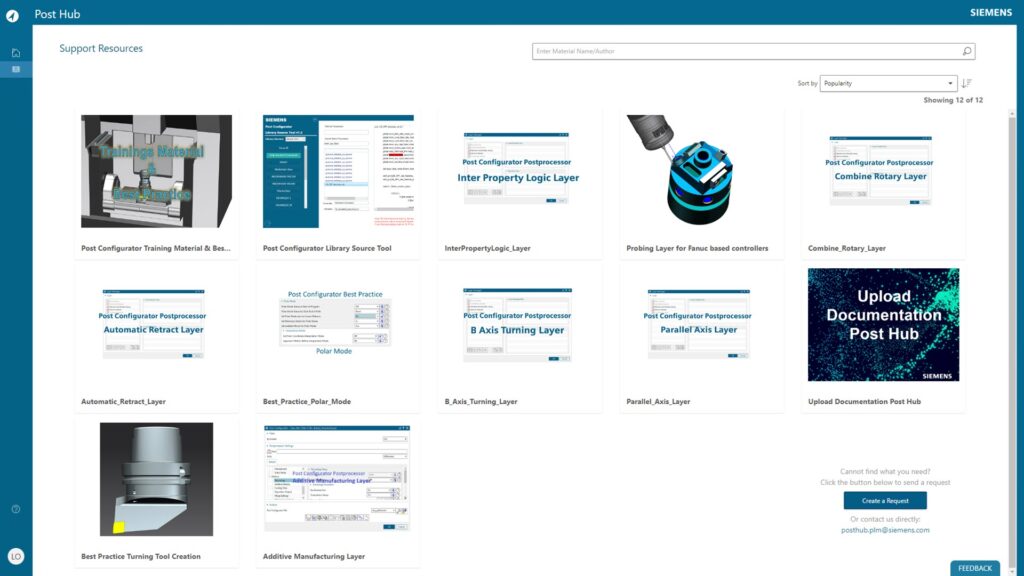

Post Hub, the cloud-based solution for postprocessing with more than 1,200 postprocessors, has been expanded with new capabilities and resources. You can now quickly display the available Smart Machine Kit Solutions (SMKS) using the License filter. The additional support resources, including training manuals for Post Configurator, help manufacturers generate production-ready programs for CNC machines and 3D printers.

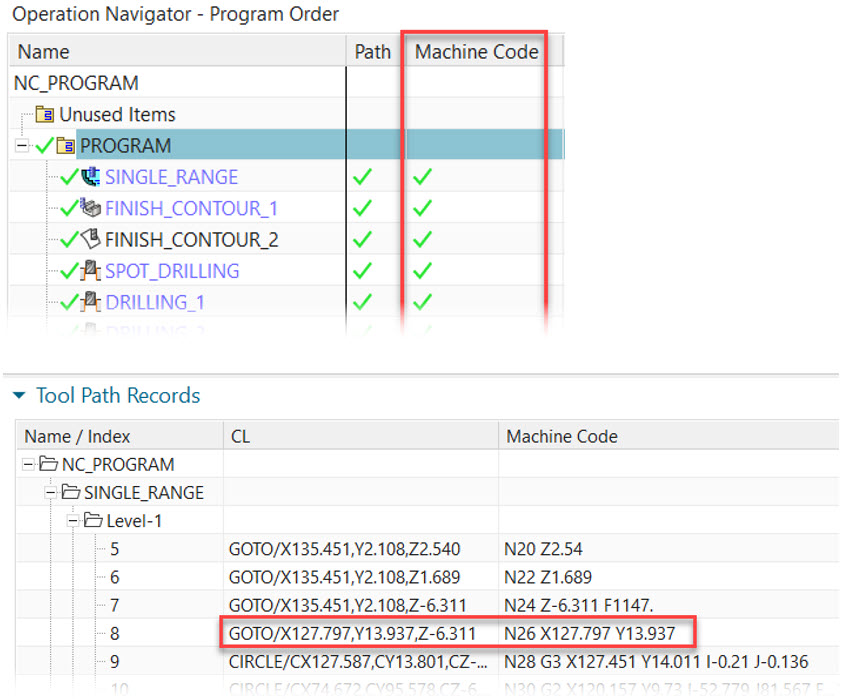

The Machine Code Performance and Reuse allows for generated NC code to now be stored in the operations to be reused for repeated simulation runs, resulting in improved usability and performance of simulations.

What’s New in NX Additive Manufacturing

Innovative additive manufacturing techniques facilitate the 3D printing of next generation parts.

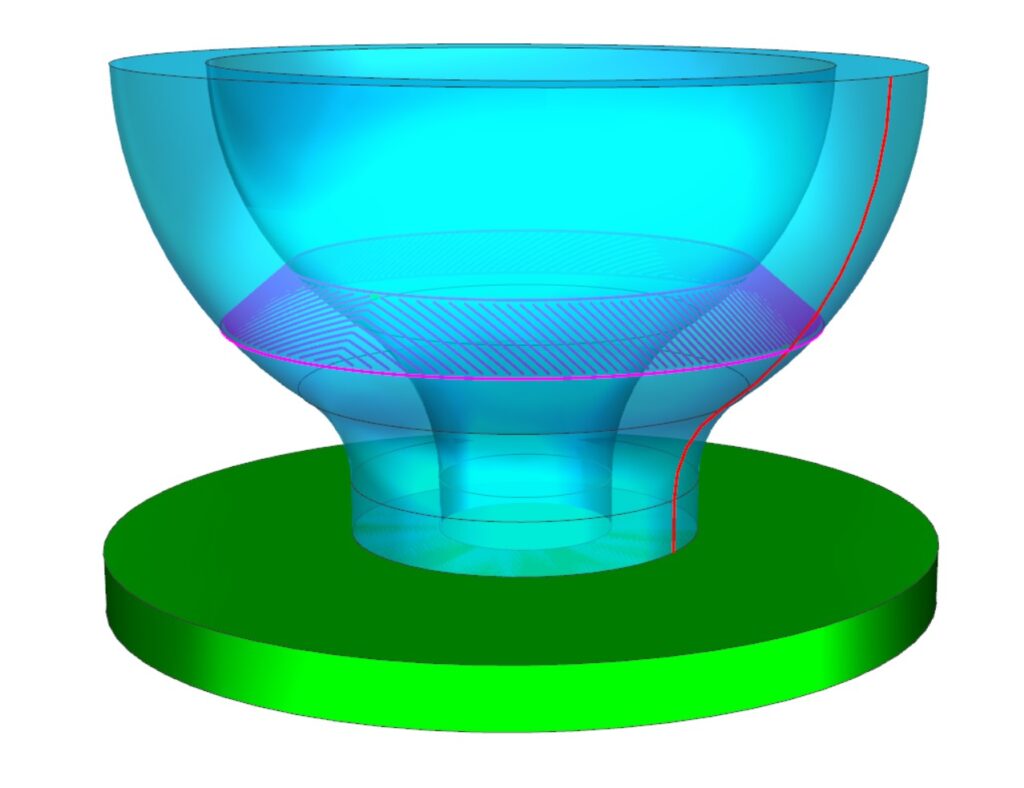

The Conical Additive Buildup is a new cone slicing method for parts, slicing the part using cones instead of planes or revolved shapes that is well suited for parts with a varying slope, such as “wine-glass” shapes. Consistent layer heights and bead height are ensured with the wedge method. Additionally, this new capability trims the new cones, optimizing the material deposition process.

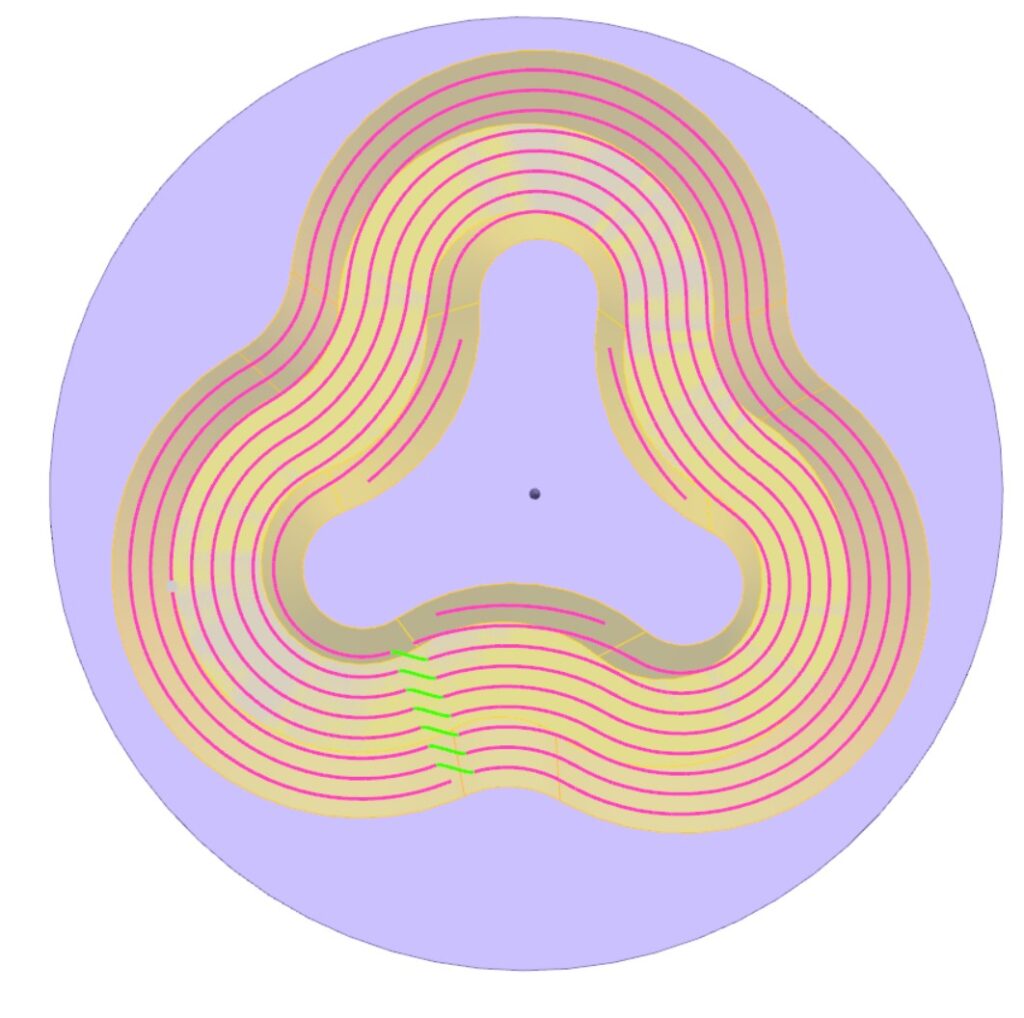

The Automated Spar Buildup will automatically fill large areas of the part with the new Tape tool, utilizing containments and drive curves. Areas that are not filled by the initial tool can be located and automatically filled with a smaller tool. This saves considerable time by eliminating manual operations to find the unfilled areas, make boundaries, and fill them.

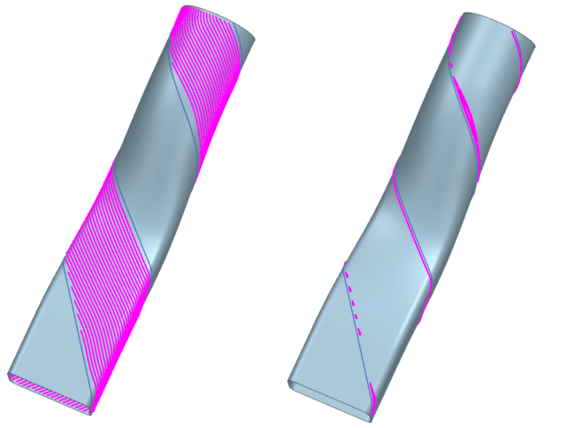

The enhancements to Stagger Distance include the addition of a smooth “S” shaped move transition from one infill to the next to smooth machine motions. You can now also stagger start points from layer to layer by Angle or Distance, mitigating the overbuild of material on the same start point on every layer. The new staggered smooth transitions ensure higher efficiency and better-quality builds.

What’s New in Manufacturing Process and Data Management

In Fixtures and Devices, clamping elements can now be classified and used to build fixture systems for mounting.

In NX CAM, you can retrieve NC tools and machines directly from Active Workspace (AW), allowing the transfer of resources from AW to your active NX CAM session using Drag & Drop. This is important for the integration of part manufacturing data management in AW.

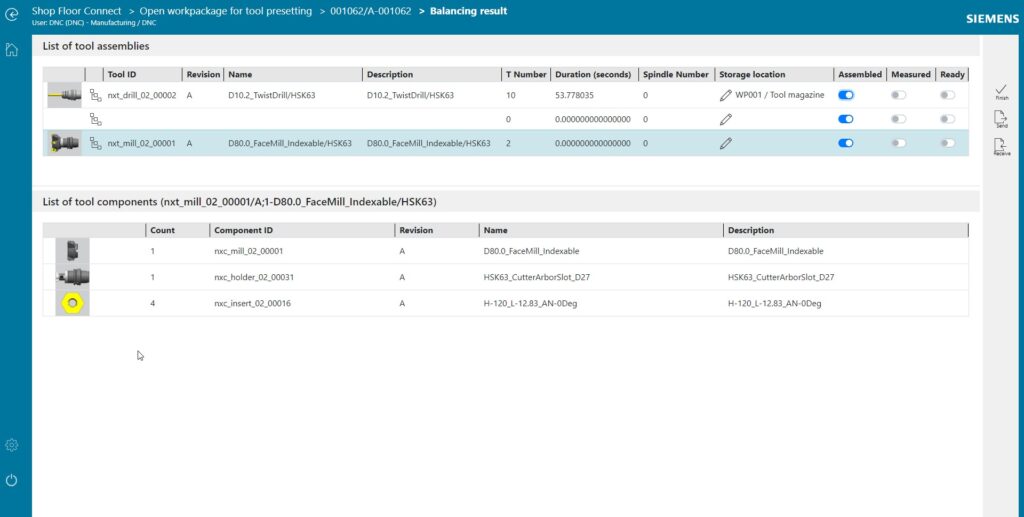

Shop Floor Connect received an extension called Resource Tracker, which is an entry level physical tool management solution for tool assemblies. The enhanced UI assists in tool management setup and tool presetting.

What’s New in NX CMM Inspection Programming

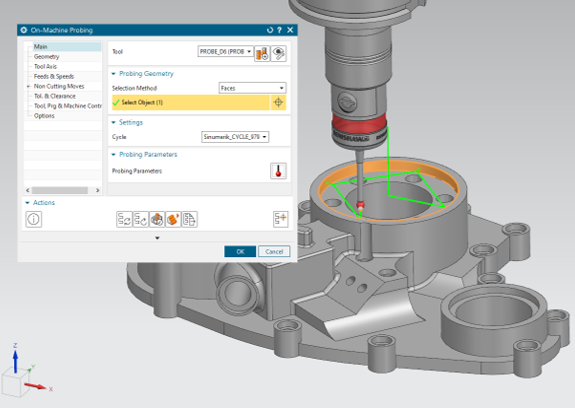

The new On Machine Probing module in NX enables programmers to easily define probing cycles on machine tools. You can create, simplify, and execute machine cycles all in one operation, while automatically recognizing the features on the 3D part.

What’s New in NX Assembly Line Planner

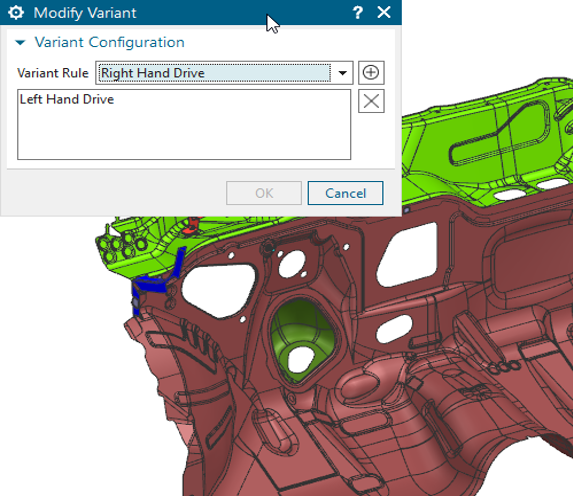

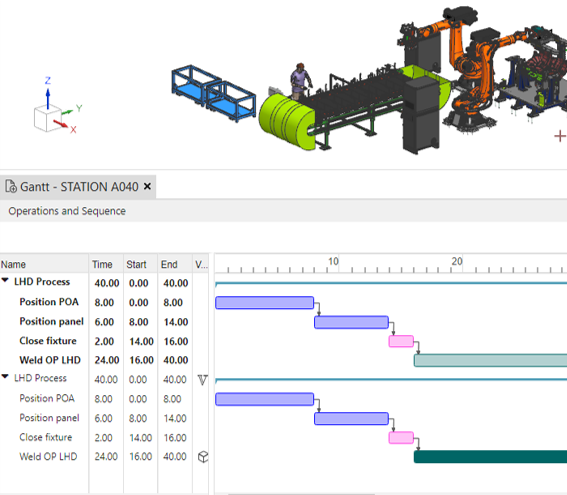

With the new Modify Variant feature, you can switch between different variant rules without leaving the session in Assembly Line Planner or having to reload any data. Both the product and the process to manufacture the product will represent the selected variant rule, having an impact on the content shown in the product navigator as well as on the operations visible in the Gantt viewer in Station Detailing.

The new Duplication feature creates a clone of an existing operation or group of operations for reuse. The clone will contain the same resource assignment but will not contain any pre-existing product or feature assignment. This behavior will help support the planning of a new variant or car model based on a pre-existing plan without the requirement to recreate a similar process manually again, therefore maximizing reuse.

What’s New in NX Line Designer

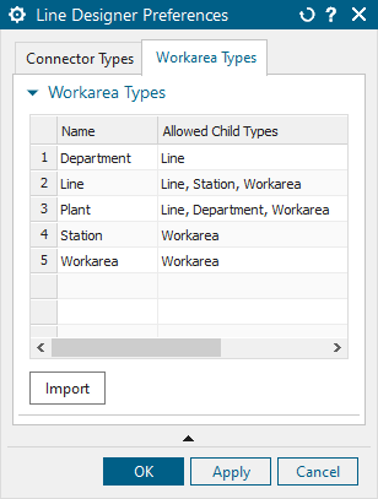

With the Allowed Child Types feature allows a user to import the Workarea-related Teamcenter allowed child type preferences to NX. This will allow the native NX users to stay in sync with the preferences set in Teamcenter.

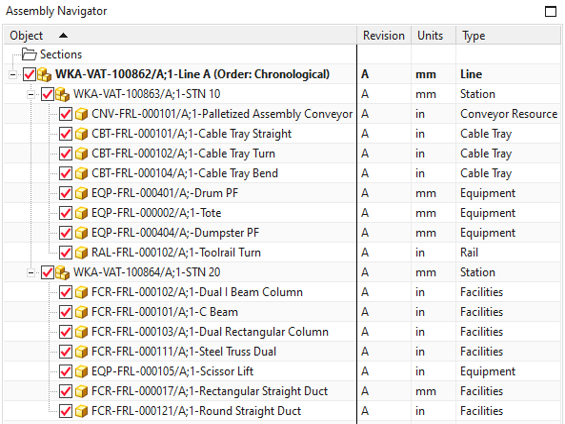

Mixed Unit Assemblies are now supported as a component. You can now drag and drop an inch unit component into a metric unit parent and vice versa in the Modeling application. This allows the support for mixed units in context thus avoiding the conversion of components.

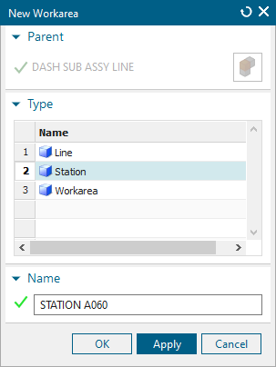

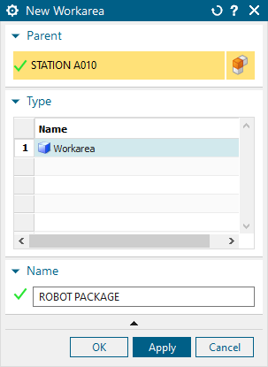

An enhancement to Workareas supports a simplified creation of Lines, Stations, and Workareas in the Plant structure. Create new Workarea types under the selected component in a plant structure or multiple nodes on the fly.

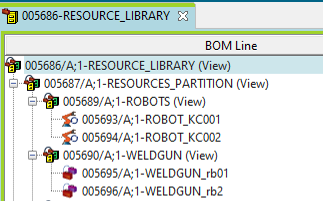

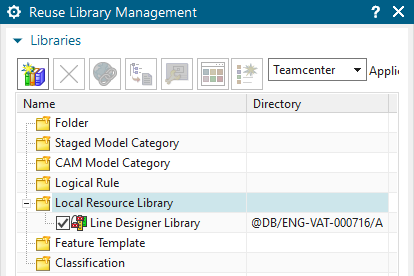

The new Local Resource Library (LRL) can be used to create a library structure to include project-specific content categorized based on robots, weld guns, robot packages, fixtures, etc. Share a scoped library with a line builder or supplier and include the structure as a part of a collaboration context (CC) object.

What’s New in NX Fixture Planner

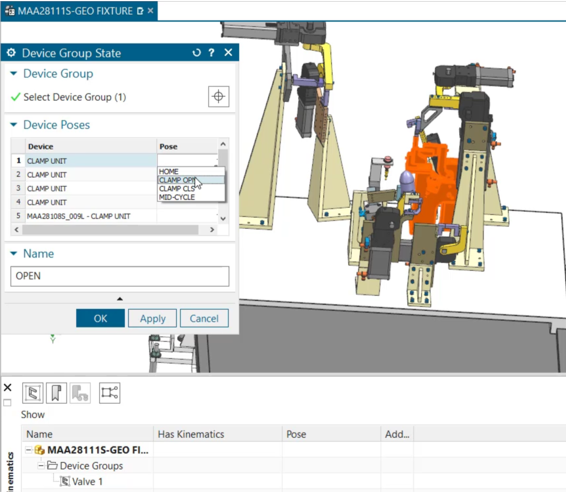

The new Fixture Kinematics navigator allows you to detail out the behavior of kinematics within an entire fixture, instead of limiting kinematics to individual clamps. You can also define common poses for a group of units.

Learn More

Join us for the YouTube Premiere on June 21 to get the full experience for the NX 2206 release!

Check out these step-by-step tutorial videos on the new NX for Manufacturing features on our online community.

For more NX information, check out the new release of NX for Design.

Explore NX’s advanced capabilities for NC programming by signing up for the NX CAM cloud-based trial. No installation is required meaning you can run NX in your browser, in just a few minutes. Try it today!