Perfecting Machining at Rolls-Royce Defense with NX CAM

Machining companies in today’s industry are constantly searching for new, innovative ways to reduce machining time and improve tool life. The recent September edition of the Manufacturing Engineering magazine featured one of the top companies in the industry, Rolls-Royce Defense, and how they are overcoming these challenges thanks to NX CAM.

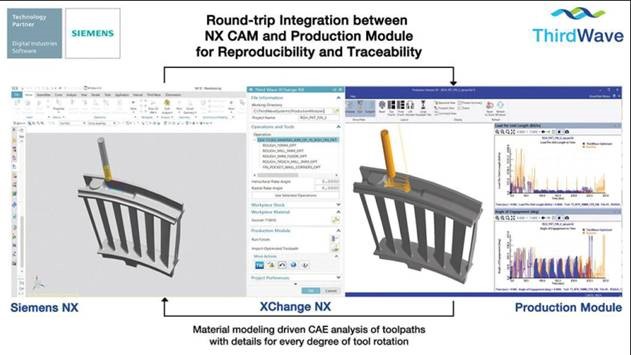

NX CAM’s advanced capabilities and its open architecture enables other specialized software systems to be seamlessly integrated. This allows highly efficient machining processes and production, higher throughput, and higher quality precision machining.

One such specialized software integrated into NX CAM and used by Rolls-Royce Defense is the Production Module of Third Wave Systems. The machining toolpath analysis simulation from Third Wave Systems is embedded in the NX software and is driven by experimentally validated, FEA based material models. Rolls-Royce has used the integrated NX experience for over 15 years.

Reducing cycle time with integrated NX CAM

The article mentions a test case run by Derek Anti, a manufacturing engineering technical specialist at Rolls-Royce. Anti discusses the test case in depth, emphasizing that the initial goal of the case using the integrated NX software was to reduce cycle time by 10 percent. The project instead achieved a 20-25 percent reduction in spindle time, resulting in savings up to $1 million per year.

“A digital thread or digital twin concept using Siemens is well established. So, as a manufacturing engineer, I don’t have to use another software and then import geometry and export back out. I open NX and there is a little launch icon in their UI, and you have the Third Wave Systems Production Module right there.”

Derek Anti, manufacturing engineering technical specialist, Rolls-Royce Defense

Vynce Paradise, director of NX CAM product development for Siemens Digital Industries Software, noted, “One of the great capabilities of the NX model-based system across CAD, CAM, CMM, and other functions that build a digital thread is the availability of the open tools that enable our partners to closely integrate their specialist solutions.” In particular, he pointed out that Third Wave Systems’ applications for material-based CAE analysis of machining processes complement NX CAM’s own advanced capabilities. “It’s good to see that our customers like Rolls-Royce Defense are realizing such high value,” he said.

Learn more

Read the full Manufacturing Engineering article here.

For more information on NX CAM software, visit our website.