NX CAM’s Multi Axis Deburring

In the latest release of NX CAM (June 2021), a new operation subtype, Multi Axis Deburring, was introduced to help you reduce programming time, create smart, collision-free cutting operations, and output optimized toolpaths for highly efficient machining.

The automated Multi Axis Deburring enables you to create 3, 4, and 5-Axis edge deburring operations when chamfers and fillets are both modeled or not modeled. NX CAM automatically recognizes the edges of parts with any level of complexity, and then creates multi-axis operations to machine the specified chamfer size.

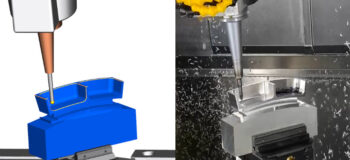

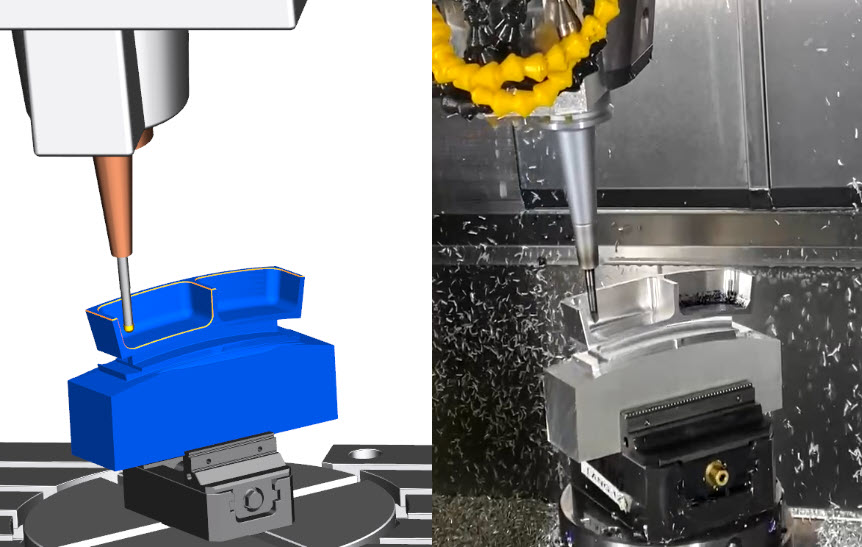

Multi Axis Deburring in Action

Multi Axis Deburring supports faster part programming by automatically detecting edges and tilting the tool axis based on user intent to provide safe and efficient tool paths. To validate the created toolpaths, you can run G-code driven simulation before you send the program on the CNC machine. Depending on the part geometry, you can quickly create different multi-axis operations, such as 3+2-axis, 4-axis rotary and 5-axis machining.

Multi Axis Deburring also supports the use of different cutting tool types, including ball, spherical, taper and lollipop tools. The advanced controls help you define the cutting pattern, tool axis and tool motions, resulting in smooth and optimized machining operations.

Learn more

Check out our video on Multi Axis Deburring for an in-depth look into the new feature.

Learn more on Multi Axis Deburring and the other great features in NX CAM in our What’s New blog.