iMFLUX uses NX to Make World-Class Molds

Siemens software helps iMFLUX achieve first time yield in the 90-percentile range.

iMFLUX, a wholly-owned subsidiary of P&G and innovative moldmaking company, is changing the way the world makes molds. They deliver superior molds, all while challenging norms and conventional processes. In their quest for one integrated solution to handle end-to-end processes, iMFLUX partnered with Siemens and tapped into the Xcelerator Portfolio. Our technology partnership identified what helps them grow and remain a world-class competitor.

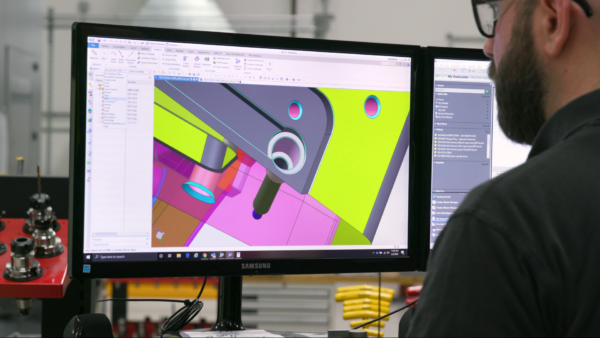

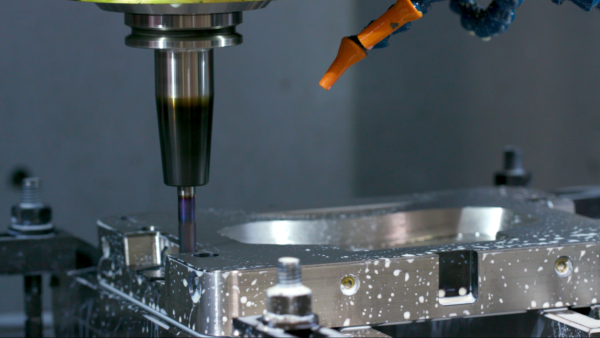

Siemens NX mold design solutions optimized faster design and mold building processes, allowing engineers to work faster and more efficiently while using pre-designed mold components from the Mold Wizard library. NX CAM software drove iMFLUX to be more competitive by automating and stabilizing their design to manufacturing processes, enabling them to house all toolpaths in one-part file type. Plus, they were able to generate CNC programs using different, infinitely customizable post processors, driving all their sophisticated machine tools using one CAM software. Advanced finishing methods in NX help iMFLUX achieve higher quality molds and first time yield in the 90-percentile range, resulting in improved operational efficiency and happy customers.

Watch the video to learn more about the benefits of Siemens software.

Additional Resources

Discover the full power of NX for mold manufacturing by launching the free NX Mold Designer and NX CAM cloud trials in your internet browser.

Learn to make manufacturing lead time an asset by reading the digital machine shop eBook.