How Automation Cuts Manufacturing Lead Time

Join us for an on-demand webinar

Digital Machine Shop: How Automation Cuts Manufacturing Lead Time

Automation is key to achieving the goal of reduced time-to-delivery – a top objective for 56% of surveyed machine shops.

Digitalizing part manufacturing is a prerequisite to effective automation, which can be applied to individual tasks, such as NC programming or to end-to-end processes.

Learn how Siemens’ NX software for CAD, CAM, CMM, robotics, and additive manufacturing transforms how you make parts, boosting your productivity.

Primary Topics:

- Automation at a level to suit your shop

- CAM specific programming:

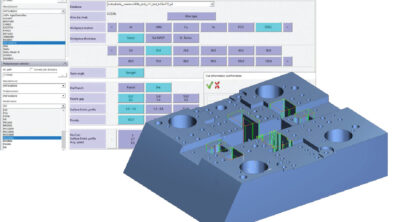

Volume-based programming

- Feature-based machining

- Knowledge capture and re-use

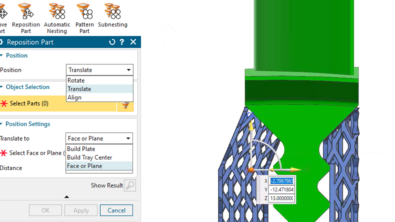

- Controlling advanced robots, industrial 3D printers, and CMMs

- Opportunities for total automation

Presenter: Vynce Paradise

Vynce Paradise heads up the NX CAM mold die and complex machining software product development team and has also led the development of the multi-axis 3D printing and CAM robotic projects at Siemens PLM Software. Vynce has wide experience in the CAD/CAM software industry and is based in Cypress, California USA.

Vynce qualified and worked as a professional engineer in the UK before transitioning to the engineering software industry over 2 decades ago. He has experience within a range of applications from embedded real time software to advanced CAM/CAM and PDM systems in sales, marketing and in the management of global product development teams.

Register and listen to the on-demand webinar now!

You may need to install the GoToMeeting Codec for Windows Media Player to watch recorded webinars.