Formnext 2018 – Siemens Simcenter 3D Additive Manufacturing Process Simulation

At Formnext 2018, we just announced our new Simcenter 3D Additive Manufacturing Process Simulation solution. As the industrialization of additive manufacturing (AM) accelerates, companies are finding that their need to get a first-time-right print also increases. However, producing an initial high-quality print has proven to be difficult. This is where additive manufacturing process simulation comes into play.

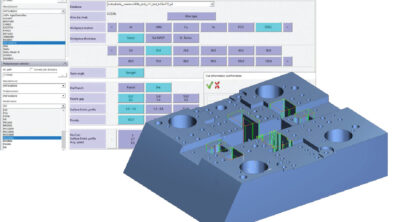

Simcenter 3D AM Process Simulaton on the left with a 3D scan of a printed blade compared with the original CAD geometry on the right showing correlation between the simulation and reality.

Simcenter 3D AM Process Simulaton on the left with a 3D scan of a printed blade compared with the original CAD geometry on the right showing correlation between the simulation and reality.

Process simulation allows you to simulate the actual printing process so that you can anticipate problems in your print. Then you can address those issues before you waste time, money, and resources on a failed print.

Simcenter 3D AM Process Simulation allows you to predict where deformations or shrink lines may occur. The system can then automatically create a compensated model that can be substituted for the original CAD model in the build tray to alleviate the found issues.

Simulation of the print process is just one more step in the overall industrial additive manufacturing workflow. As the AM industry evolves and moves towards printing production parts at scale, the simulation of the AM process will become evermore important.

Look for more details about the exciting Simcenter 3D AM Process Simulation soluton here and in other places across the Siemens website over the coming weeks as we continue to work with our customers to industrialize and simulate their AM processes.