Aerospace manufacturer gets best of both worlds: CNC programming and machining

“By combining the best toolpaths from VoluMill with the comprehensive programming environment of NX CAM, Steelville Manufacturing is enjoying significant productivity gains and truly getting the best of both worlds.” Adam Menz, NC User, Steelville Manufacturing Company

Expert in milling, turning and waterjet cutting

Steelville Manufacturing Co. (Steelville Manufacturing) specializes in making components for the aerospace industry, and is a Boeing supplier. The company cuts all kinds of materials, from plastic to titanium. The largest segment of its business is aluminum airframe components. Steelville Manufacturing primarily uses 4- and 5-axis Okuma and Makino machines. It has been using NX™ software from Siemens PLM Software since 2006, and has three programmers who use NX exclusively.

Initially, Steelville Manufacturing used VoluMill Universal™ software, a standalone product from Celeritive. The company used it to rough hard materials, an area in which it believes VoluMill software performs quite well. It would then integrate its NX programs with the VoluMill Universal programs to produce the numerical control (NC) code that went to the machines.

Steelville Manufacturing considers VoluMill to be especially well suited for removing large volumes of hard materials. It employs a smooth spiral pattern that helps precisely control the tool engagement, avoiding overload conditions. When VoluMill pushes that spiral into corners with an intermittent cut, it enables the user to make sure that maximum feed rates are being used through the portion of the spiral that positions for the next engagement. This helps it keep metal removal rates maximized and air cut time minimized.

While the use of VoluMill for roughing hard materials was improving machine tool utilization, the use of two software systems for programming was less than optimal. Valuable time was spent moving geometry between the two systems, and tracking the state of the uncut material. The stock would have to be saved in VoluMill, exported to NX, and then used for subsequent machining steps. When changes were made, that meant that all the steps needed to be repeated because there was no associativity between systems.

Integrating systems

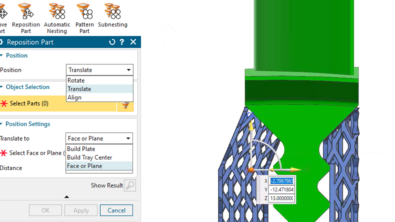

In 2010, Celeritive partnered with Siemens PLM Software to provide its VoluMill cutting technology as a plug-in for NX CAM. This plug-in is fully integrated into the NX environment, enabling it to be engaged in the operation navigator toolpath management system while staying associative to the NX geometry and tracking the uncut material in the same way as other NX CAM operations. Steelville Manufacturing started using NX CAM with the VoluMill plug-in in 2011.“

“When we learned that VoluMill was available as an NX plug-in, we were very enthusiastic and switched to it right away,” says Justin Wright, one of the company’s NC machine users. “It is much easier to use the NX interface than the standalone Universal interface. Not only does it allow us to eliminate all the duplication and file translation, but the integration of the VoluMill roughing cuts in the NX operation navigator and uncut material tracking are saving lots of programming time.

“We are seeing our programming time decrease by as much as 50 percent just by switching to the integrated plug-in. Also, we post all our programs to the same place, so we no longer need to stitch together programs from two different sources for the machine to run. I use the VoluMill plug-in on probably 90 percent of my NC programs now, so we realize cost savings and convenience, both of which are greatly appreciated!”

The plug-in helps smooth out the process by eliminating the need to translate files and, as a result, translation errors. Because the NC users have the modeling function, they can save time importing and exporting data between systems. The NX CAD capabilities, measurement tools and other functions make the system very useful.

Boosting productivity

“Having the toolpath that we want in the NX environment amplifies the benefit that we’re getting from the VoluMill roughing,” says Adam Menz, another Steelville Manufacturing NC user.

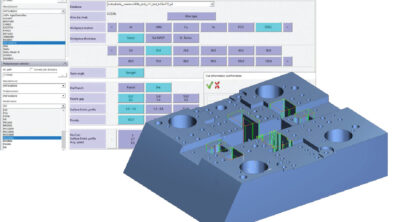

Steelville Manufacturing continues to improve its processes with NX CAM and the VoluMill plug-in. The company prefers using the NX Cavity Mill roughing approach when there are more walls and obstacles in the volume, and VoluMill when the tool can run deeper cuts with fewer obstacles.

The company initially focused on hard materials, where metal removal rates can double with VoluMill, but it has also achieved productivity increases on large volumes of aluminum. The company continues to push the technology, running axial depths of cut up to the maximum flute length and radial cuts ranging from 0.030 to 0.055 inches in hard materials.

“By combining the best toolpaths from VoluMill with the comprehensive programming environment of NX CAM, Steelville Manufacturing is enjoying significant productivity gains and truly getting the best of both worlds,” says Menz.

Client’s Primary Business:

Steelville Manufacturing Co. was founded in 1959 and is a contract machine shop specializing in milling, turning and waterjet cutting. In 1966, the company was approved to work for McDonnell Aircraft Company (now Boeing). In January 1993, Steelville Manufacturing became a preferred supplier to Boeing and has continued its relationship since. The company has 130 employees at its facility in Steelville, Missouri.