Siemens Xcelerator Marine Solution: Industry Challenges | Part Two

Introduction

The marine industry is constantly facing challenges, especially over recent years with new introductions of specific regulations and standards. From the need to meet environmental standards to needing more space to be successful, the often talked about concerns do have an answer. The end-to-end Siemens Xcelerator Marine Solution can provide marine companies with assistance throughout each step in the lifecycle.

Challenges Within the Marine Industry

The main drivers to challenges within the marine industry are the environment itself and the products that the market are requiring. The market is requiring faster, yet more complex ships to meet the needs of delivering items quicker. With complexity comes more intricate components. Ship owners are requiring better performance out of their ships through this to cut down on maintenance costs. This is to keep them performing better on a consistent basis.

One of the most demanding challenges of the modern marine industry is the migration from fossil fuels to others. The future lies in the electrification of propulsion or using batteries cells powered by green hydrogen or ammonia. The problem is not the technology itself, but their efficient production, storage and handling. The use of an end-to-end solution that considers the ship as one part of the long shipping chain is key.

Meeting environmental industry standards

One of the biggest struggles for the marine industry is the continuous changes within the environmental standards. The standards are not a frozen rule but are changing to accommodate a clean and green future. With constant changes, the new regulations can outdate ships as far as the life cycle of the ships. This means that in order for the ship to sustain a healthy lifecycle, it is necessary to overcome this mismatching. If not possible to overcome, companies will need enough tools to allow an efficient and sustainable retrofitting of the vessels.

Another challenge that affects these same ships is struggling with building facilities. The existing infrastructure like their workshops, machines, docks, slipways and other shipyard and facilities, are in some cases located in old places where business has grown around them. This has caused them to not be able to expand outwards to have the space to make the necessary changes. Beyond the environmental changes, people and businesses around the world are requiring faster and larger ships to get orders sooner. With an outdated shipyard, this leads down a road where it might be hard to stay afloat as a business.

Trying to compete without an end-to-end solution

The main priority of any business is to provide a solution for the demands of people. Today, the demand for larger shipments and at a faster rate is causing the design of ships to change. Most shipyards are going back to the brainstorming phase to come up with new ship designs. These designs are not only going to meet the demands, but future-proof ships for upcoming years. Without an end-to-end solution through the lifecycle of shipbuilding, companies are struggling to adhere to standards at a moderate pace. The truth of the matter is, the constant change in demands from ship guidelines to the demands placed on efficiency of ships is running some shipyards out of business.

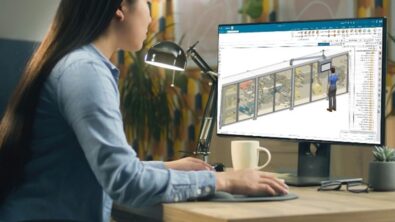

Shipyards are now in desperate need for a tool that allows them to consider the overall operation of the ships from the early stages of the design process till the decommissioning. Without this line of sight into the design, companies are already putting themselves at a disadvantage. To be successful in the future, shipyards need a complete suite of design tools all the way through visual prototyping in order to grasp the detail needed to see a design come to fruition.

What changes need to happen?

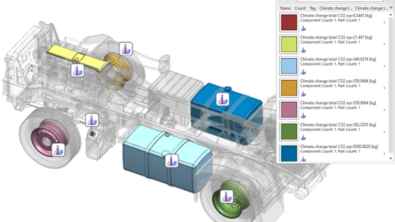

The best thing that companies can do is demo tools that can simulate the fabrication process. Instead of wasting time and material on prototyping new parts, the Siemens Xcelerator Marine Solution can simulate the fabrication process of new designs. The fact is that the marine industry is big. In both the size of the ships and the number of parts that are associated with them. When we talk about how important the design quality and user experience is, it is important because of how detailed the shipbuilding process is. There are manufactured parts that are constructed down to tenths of millimeters. There are also submarines that have cables the length of more than 300 kilometers just to name a few.

By showcasing the capabilities and design success that can be found with the Siemens Xcelerator Marine Solution, this might encourage companies to expand. One of the biggest challenges that is ahead of the marine industry is to overcome the demands of performance. With the Siemens Xcelerator Marine Solution, we need to guarantee the customers that there is not going to be any issue in performance. This guarantee is no matter the size of construction or number of elements within the design.

A complete solution

The Siemens Xcelerator Marine Solution is the only solution within the marine industries with its kind of capabilities. It is providing shipbuilders with a complete solution for designing, prototyping, and expanding throughout the entire lifecycle. Rafael De Gongora, Senior Director of Shipbuilding from Siemens Digital Industries Software, has said that the new functionalities will amount to a 20-30% improvement in design time. On top of the time savings, companies could see reduced fabrication time while avoiding the need for any reworks. This is a major win for all within the marine industry. A solution dedicated to reducing waste material, more efficient design, and a more consistent lifecycle management is the complete solution for contenders in the marine industry.