Why Top Performers Are Embracing Design for Additive Manufacturing

Download the whitepaper How Top Manufacturers Are Planning for the Future to learn more about 3D printing and how is changing product development.Additive manufacturing or 3D printing is certainly a trend these days. A recent report from Tech-Clarity shows that 89% of top performing companies will look at new ways to design for additive manufacturing in order to take advantage this technology in their business. Growing pressures and competition that arise from the global economy and fast pace of technological changes means that companies must adapt to keep up. One way they are doing this is through implementing 3D printing in their manufacturing processes.

Download the whitepaper How Top Manufacturers Are Planning for the Future to learn more about 3D printing and how is changing product development.Additive manufacturing or 3D printing is certainly a trend these days. A recent report from Tech-Clarity shows that 89% of top performing companies will look at new ways to design for additive manufacturing in order to take advantage this technology in their business. Growing pressures and competition that arise from the global economy and fast pace of technological changes means that companies must adapt to keep up. One way they are doing this is through implementing 3D printing in their manufacturing processes.

3D printing opens the door to a lot of possibilities for product developers. For one thing, you can nowmanufactureproducts with organic and complex shapes that were previously too expensive, time-consuming or even impossible to make using traditional manufacturing methods. Another great example of a change that additive manufacturing is driving in the product development arena is making products lighter and stronger through the useof lattice structures. Of course, additive manufacturing also shortens the product lifecycle, making it possible to deliver products much faster—a clear competitive edge in the product development industry.

All of this requires a special set of design tools, though, to ensure you are getting the most from additive manufacturing methods. A couple examples you might consider are… Can the part an engineer designed actually be manufactured? Will there be any failures due to wall thickness? What about special support structures for areas of overhang?

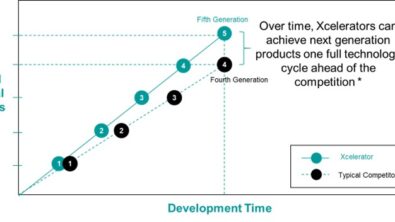

Going back to a discussion with Robert Haubrock on the next generation of design, there was a clear standout on where industries are headed. The new tools available in NX 12 are influenced by this need for manufactures to deliver products that are more robust using less materials and get them to market much faster than ever before. As a result, we now have next generation design tools in NX 12 specifically for the purpose of design for additive manufacturing. Design checkers to identify build issues early, and lattice design for lightweight parts are just a few examples of the tools you’ll find in NX 12 to help you get more from your experience.

Read the whitepaper to learn how 3D printing in the automotive industry will play a big role in helping companies achieve a competitive advantage.