Designing for sustainability with CAD and PLM | Phoenix Contact partners with Nexpirit for sustainable product design

Welcome to another recap of the Next Generation Design podcast for the episode: Driving Sustainability in Design: Insights from Nexpirit and Phoenix Contact. You can watch the full video version of the episode below.

On this episode of the Next Generation Design Podcast, host Greg Arnot speaks with Lucas Dann, Mechanical Engineer in Manufacturing & Management at Nexpirit, and Lennart Gorholt, Senior Project Manager at Phoenix Contact Group. Together, they explore how sustainability can be seamlessly integrated into the design process, how companies can leverage Siemens’ NX and Teamcenter to track and optimize environmental footprints, and why waiting for “perfect data” is no longer an excuse to delay action.

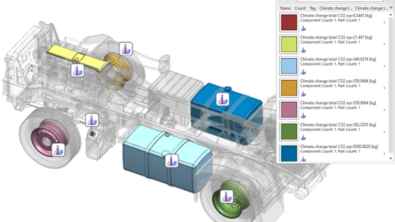

Lucas and Lennart share insights into how digital tools empower engineers to measure sustainability impacts early in product design, how Phoenix Contact developed an automated system for CO₂ footprint calculations, and the real-world impact of shifting sustainability efforts “left” in the design cycle.

What you’ll learn about in this episode:

What is Phoenix Contact?

Phoenix Contact Group is a global company headquarter in Blomberg, Germany that develops sustainable solutions, specializing in the fields of electrification, networking and automation. They partner with Nexpirit for their PLM solutions.

What is Nexpirit?

Nexpirit is a digitalization and PLM company based in Porta Westfalica, Germany that focuses on building software solutions for customers around the globe to help them reduce CO2 footprints and phase out materials/substances that do not apply to global legislations.

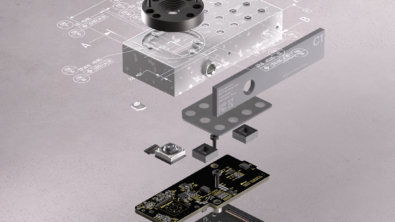

As a Siemens Smart Expert Solution Partner, Nexpirit also helps develop solutions connected with Siemens software products such as Teamcenter and NX. The award-winning NX Design for Sustainability module (mentioned throughout this blog and podcast as NX Sustainability Impact Analysis) in NX CAD is a joint development between Siemens and Nexpirit, as Nexpirit provides the environmental datasets for 19 environmental KPIs.

How Nexpirit integrates sustainability into PLM

Nexpirit helps customers shift left by integrating sustainability into PLM, instead of solely doing a traditional life cycle assessment (LCA) which typically happens very late in the process once the product is complete. This shift gets more people involved in making decisions that are sustainable earlier on in the process and not waiting until it is almost too late to make changes. They can choose alternative materials, increase recycling content of the material or adjust by finding alternative suppliers. Their sustainability solutions start at the design and PLM stage, such as within NX and Teamcenter.

Why integrate sustainability into PLM?

After understanding how Nexpirit integrates sustainability into PLM, he asks Lennart of Phoenix Contact how their collaboration with Nexpirit began and why they decided to apply sustainability calculations into the design and PLM stages themselves.

Phoenix Contact began their collaboration with Nexpirit due to the need to deal with KPIs for 10,000s of materials and around 100,000 products. They needed a systematic approach to do the calculations, and Nexpirit helped to put that system together and understand environmental impacts of each material even as they change the design or suppliers.

From trying to understand material makeup, doing calculations to determine environmental impact of each material and deciding how they can make changes to material selections and design that will result in a more sustainable product, they realized they needed to shift sustainability earlier into the product life cycle. It is both cheaper and easier to make changes when they happen early in the beginning of the design stages since you have a free choice to play around with different ideas, different materials, etc. Lennart explains that if you wait until later to make changes, it is more challenging. Once you release a product, your customers are used to the product, its dimensions, technical abilities an features, etc. Additionally, you would have to adjust production as well and make changes across the supply chain as you change the machines, materials, suppliers, etc.

With all of this understanding, Phoenix Contact understood that they needed information that allow their designers to make decisions early on in the design process and understand the environmental impact of different materials. Now, they utilize a database designed together with Nexpirit, stored in Teamcenter. The database gets regular updates and they can track changes over time.

How Phoenix Contact balances sustainability, cost and technical requirements

Greg then asks Lennart how the design process begins with new products when they’re taking sustainability into account. Lennart says at Phoenix Contact, they begin with defining the requirements. They need to ensure a balance between sustainability and technical regulations, technical requirements and cost. They need to understand the footprint of a product and how to reduce their emissions via product design. If they are introducing a new technology, they need to understand if the impact is better or worse environmentally. They look at how much energy is consumed, how much material is used and what the product feasibility is. When the design costs less and has less of an environmental impact, then they know they are ready to move ahead.

The value of NX Sustainability Impact Analysis for product design

As previously mentioned briefly, NX Sustainability Impact Analysis is an award-winning module within the NX CAD application that enables you to perform sustainability calculations, what-if analyses and material optimizations during the design phase.

Lennart believes the product brings values to employees who may not be experts on the topic of sustainability, as it supports them in making data-driven decisions based on environmental data. An engineer may be perfect at designing products but not an expert in life cycle assessments. With NX Sustainability Impact Analysis, the data is provided with just a few clicks to understand environmental impact of a design and material selections. As they play around with different designs by making changes or swapping out different materials, they can compare the impacts and how the environmental footprint changes just from looking at the numbers the analysis provides. Thus, their engineers can optimize a product easily and early in the design phase without having to be an expert.

How was Nexpirit involved in the development of the NX Sustainability Impact Analysis product?

We then learn more about how Nexpirit was actually involved in the development of the module, which was first released in the December 2022 release of NX. The environmental experts from Nexpirit provided datasets for the calculations. Working together with the product development team and product manager, Shirish More (who was featured on an earlier episode this season on AI), they iterated on a few different concepts and got customer feedback across different industries, including from Phoenix Contact, on what would provide the most value-add. They received the same general feedback: engineers want the right metrics to identify where to improve on sustainability.

Throughout the development process, they understood that some of the KPIs may need to be simplified as it was not enough to just provide a bunch of different numbers/KPIs, and the module should also provide ways to make the design better. So, not only can you perform sustainability calculations but you can also conduct what-if analyses and get machine-learning enabled optimizations based on your design and the real-world data. With each sprint in the product development process, we are adding new capabilities to the module. Lucas highlights that we recently added the ability to consume computer-aided manufacturing information from NX into the CO2 calculations, so energy consumed from manufacturing production, how much cooling fluid is being used, etc. is taken into account with the calculations, giving you a fuller picture of the entire impact along a product’s lifecycle.

Greg also asks Lucas why Nexpirit chose to partner with Siemens for integrating their sustainability solution into software. On the technical side of things, Lucas states that leveraging Teamcenter gives flexibility that is “open, modular and easy to extend” and that NX is “perfect for adding your own solutions.” But he also notes the connection Nexpirit has with Siemens as a PLM partner. “The chemistry that we had with the product development team on the NX team, trying to reach the same goal and target, helping industries to reduce their impact, and having the same mission statements was one of the reasons why we kind of came into that partnership with Siemens here,” he states.

How does Phoenix Contact handle the calculation of environmental product declarations?

Phoenix Contact has around 100,000 products, so doing environmental calculations one by one manually would take far too long and make it difficult to ensure data is up-to-date as changes can happen frequently. Thus, they decided they needed to get rid of any manual input by automating the calculations for their products, whether they are early in the design stage, well-developed products already on the market or even retired products. They integrate their systems so that they have current data, bill of materials and value chain that allows them to rerun calculations and see feedback.

With the calculations themselves being automated, Lennart says that the most challenging part is not doing the calculations, but checking and understanding the results. With 100,000 products, there are 100,000 results and they need to judge whether the results are right or wrong, if there are miscalculations or updates pending, if a product is ready for release, etc. They do have an automatically-calculated quality indicator, and this allows them to see which products increase or decrease in footprint and where that change may be coming from. Additionally, they use product “families” to simplify the process. If a product comes in multiple colors, they group the products together and see the range of CO2 footprints for each color. If it is within an acceptable range/variance and the difference can be explained, the product is good to go.

Phoenix Contact has seen huge benefits in efficiency with automation allowing them to scale. Instead of spending months doing the calculations, they can do the calculations quickly and instead focus their time on how they can make impactful changes or create alternatives.

Future technologies in sustainable development

Greg then asks what kind of technology Lucas thinks will play a big role in sustainable product development. Lucas mentions the Digital Product Passport, which is an initiative driven by Europe that allows communication of environmental data. In the future, not only will price and technical information for a product be required, but the environmental impact as well.

He also mentions data exchange and AI. With data exchange, KPIs and calculations can be standardized across industries. With AI, he notes that it does not generate data, but it helps us to make the right decisions by pulling in the right data, comparing supplier data, filling in the gaps, etc., but companies will need to be transparent where AI is involved throughout their processes.

How Phoenix Contact empowers employees to make sustainability a daily priority

Lennart says that their employees love and care about sustainability, they do not need to be convinced. They want to contribute to making a better world, so when they need to make changes for better environmental impacts, they are on board. So it is less about convincing them that making an impact is important, but more about training them how to create an impact. The key elements for them are around materials and usage, so Phoenix Contact trains their employees how to contribute and bring ideas that change the footprint of a company.

“Everybody loves this topic,” Lennart states, “So it’s really about getting them in a situation that they can participate and then they are completely on fire and loving it. I barely met people who say, ‘I don’t believe in decarbonization.’ Everybody is happy to do it. It’s mostly about having a chance to do it.”

How to integrate sustainability into product design

Lennart and Lucas then share advice on how other companies who are looking to be more sustainable can stay ahead of the curve.

Lennart says the key for them is to constantly look for new alternatives with materials, which is a process involving a lot of trial error where some days you may constantly fail, but it is all about trying and finding out what you can do. As examples, he mentions bio-based materials and recycling of plastics, which may not be where Phoenix Contact needs them to be yet, but he says they must constantly find new ways to try and examine how to resolve challenges and alleviate barriers, understand what can be feasible and what needs to be changed in order to get it done. It is an iterative process, and Lennart encourages everyone looking to prioritize sustainability to always rethink everything. “There is no standard way to solve our questions,” he says. He also emphasizes that there is “no final data,” as the numbers are always changing, but that we don’t need final, precise data in order to start making progress and improving over time. “If you wait for it to be perfect, you will wait for all your lifetime. So it’s really about taking the first steps and learning on the way…constantly learning and doing and not waiting or hesitating. It’s really about being keen, being brave to just start the journey,” he advises.

Lennart also reminds us that we can’t do it on our own, it is important to get in contact with suppliers as “their footprint is our footprint” and customers as “our footprint is their footprint.” Looking ahead to the future, he believes that more and more companies will move to prioritize sustainability and that the more sustainable option will be the less costly option too. We will move more and more to a circular economy as the demand is increasing. With this, we can think differently and creatively.

Lucas advises that you shouldn’t see sustainability as a burden, but a door opener to new markets. Sustainability can differentiate you from your competitors, and as sustainability becomes a more important requirement, it’s important to start early. “Get your BOM structures in place, get your material information in place, and then start doing the first calculations and start optimizing.” He emphasizes Lennart’s comment about how data is never final, as once you do a calculation it is outdated, the supply chain changes, electricity changes, etc. so you cannot wait to be ready to start as you’re never fully ready. Sustainability must be built into the DNA of a company.

He reminds us that with the NX sustainability solution, there isn’t any additional burden for engineers to see the environmental impact of their design and get recommendations for how to improve. Just starting with NX Sustainability Impact Analysis, you can begin to optimize your designs and processes in the early design stages. “Start getting the first CO2 values and then kind of start to optimize from there, get additional metrics in, get your supply chain data in, and then you already have embedded it in your development process without extra effort,” he concludes.

Check out the full episode to learn more about sustainability in product design, Nexpirit and Phoenix Contact in detail.

Continue listening to the Next Generation Design podcast.

Want to learn more about NX CAD software? Check out our website or try it for free.