NX | Tips and Tricks | PCB Exchange – Validating a Design

In our latest NX™ software Tips and Tricks video, we dive into PCB Exchange and how it can be used to validate your printed circuit board designs. In this video, we look into setting up part attributes, generating validation reports, and analyzing the results.

Check out the video below or scroll down to learn more about PCB Exchange.

Why validate your design?

Validating your design is a crucial step in improving product quality. Identifying potential design issues before production allows you to make necessary changes early in the process, saving valuable time and resources while reducing manufacturing costs.

Additionally, validation tests serve as an excellent tool for ensuring design compliance. The process checks for adherence to industry standards, company-specific guidelines, and customer requirements, ensuring the final PCB design meets all necessary specifications and regulations.

Setting up part attributes

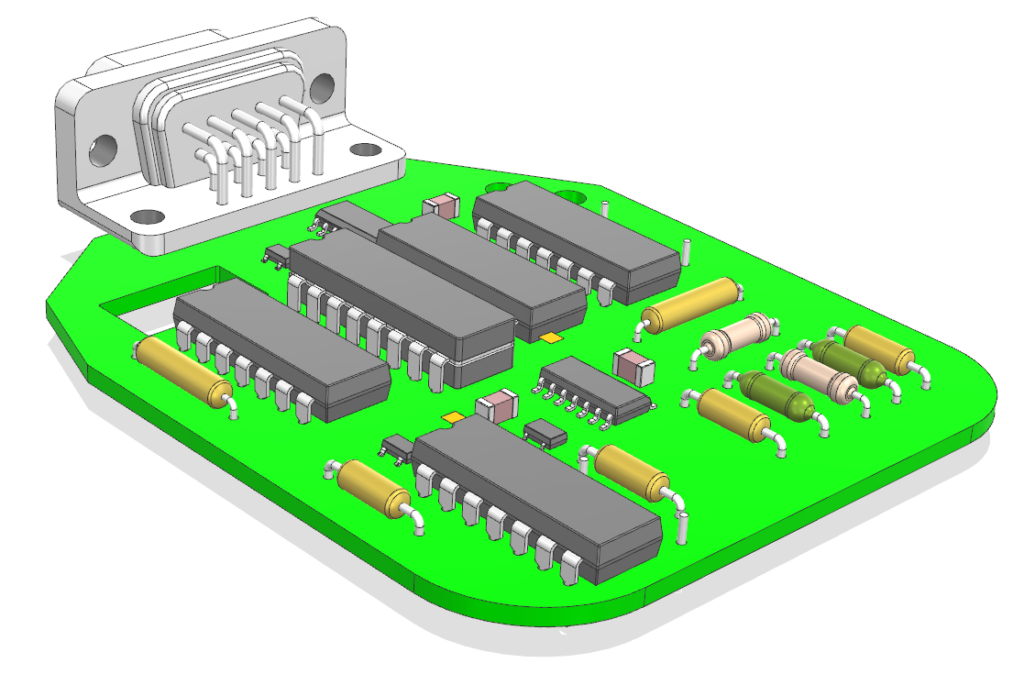

Before we validate our designs, we must first set up the proper board, component, and drilled hole attributes. This ensures that all the data displayed in our results is accurate and complete.

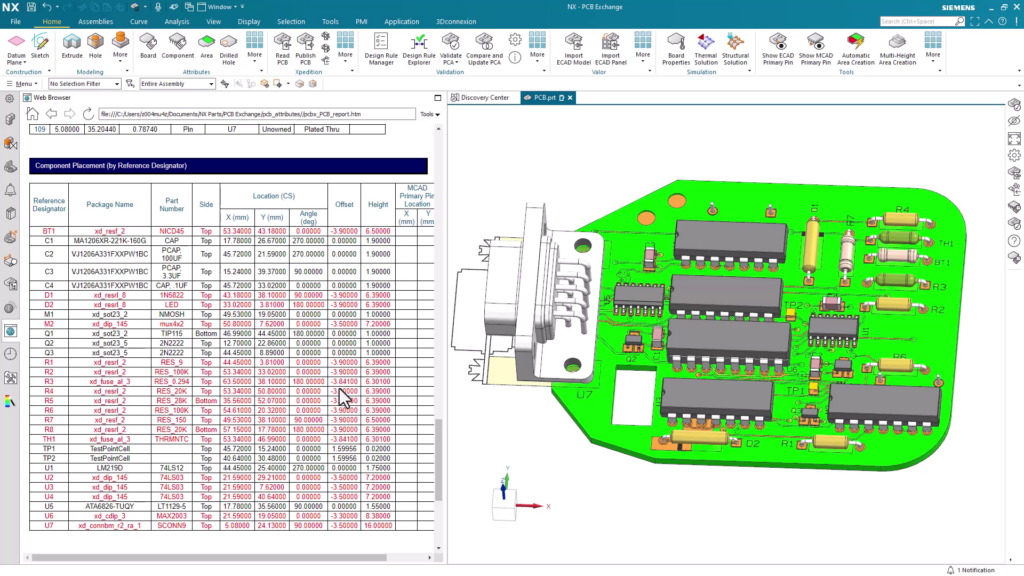

When we run our validation tests, the system produces tables that showcase the components of our printed circuit board. The content in these tables varies depending on the validation test used, but generally, the attributes corresponding to each test are displayed. Let’s take a deeper dive into three of these tests.

Validate PCA

One popular validation report for PCB Exchange is Validate PCA. The Validate PCA tool offers the most comprehensive validation test for PCB designs in NX, checking for common printed circuit board issues and ensuring that your design meets specified requirements.

A key benefit of the Validate PCA tool is its ability to catch problems early in the design process. By identifying design rule violations, connectivity issues, and other potential problems, designers can address these concerns before finalizing the design. This saves valuable time and money compared to discovering issues during manufacturing or assembly. The detailed Validate PCA report also provides valuable insights into the identified issues, enabling designers to quickly understand and resolve them.

In addition to error and warning messages, the Validate PCA command generates detailed tables for board dimensions, part summaries, drilled holes, component placements, and component quantities. These tables offer a quick reference to summarize your PCB assembly.

Lightweight and Component Report

In addition to Validate PCA, two other reports are available in PCB Exchange: Lightweight and Component.

The Lightweight Report is a concise, easy-to-generate summary that highlights key design information, such as part properties, assembly structure, and manufacturing-related data. It offers a quick and efficient way to communicate essential design details without requiring a comprehensive, detailed report. The Lightweight Report is especially useful for quick reviews, design status updates, and sharing design information with stakeholders who don’t need in-depth technical details.

In contrast, the Component Report in NX provides a more detailed and comprehensive overview of individual components within the design. It includes in-depth information about specific parts, such as material properties, manufacturing specifications, and other relevant technical details.

Next steps

After validating our printed circuit boards in PCB Exchange, the next steps typically involve preparing the design for manufacturing. This includes generating the necessary manufacturing files and assembly drawings, then uploading them to PCB Exchange Connect.

From there, designers can use the platform’s supplier integration capabilities to send design data directly to their preferred PCB manufacturers for quoting, ordering, and production. Throughout this process, PCB Exchange Connect maintains a comprehensive audit trail, allowing designers and project managers to track the manufacturing status and ensure a smooth transition from design to production.