The Evolving Dynamics of Supply Chain Relationships in A&D

The aerospace industry is no stranger to constant evolution and innovation, driven by cutting-edge technologies and changing market demands. Within this dynamic environment, the supply chain relationships between aircraft primes and suppliers have been undergoing significant transformations. In recent years, the aerospace industry witnessed a notable shift in the way primes and suppliers collaborate, driven by various factors such as technological advancements, globalization, and changing business models. This article explores the changing landscape of prime-supplier relationships in aerospace and its implications for the industry.

Collaborative relationship in aerospace and defense supply chain

The aerospace industry relies on intricate and interdependent supply chains, where disruptions at any level can have far-reaching consequences. Primes recognize the importance of building resilient supply chains by integrating suppliers more closely. Collaborative efforts such as joint planning and risk mitigation strategies are common. This integrated approach ensures greater transparency, efficiency, and adaptability in the face of market fluctuations. But despite this focus on collaboration, major primes historically held the upper hand in supplier relationships due to their dominant market position and control over design and specifications.

But a new balance between insourcing and outsourcing is at play trading manufacturing cost vs innovation. Less valuable commodity products have always been pushed further and further down the supply chain. It is here that margins are squeezed, and businesses fight for market share. On the other hand, highly innovative products with exclusive capabilities and trade secrets remain with specialized suppliers who can preserve differentiation and protect intellectual property, thereby boosting profitability.

Aerospace Technology

With the rise of specialized suppliers and advancements in aerospace technology, the power dynamics begin to shift. Such suppliers are increasingly seen as strategic partners, bringing expertise, innovation, and cost-saving solutions to the table. Primes are recognizing the value of collaboration and establishing more balanced relationships with their strategic partners, leveraging partner capabilities to enhance competitiveness.

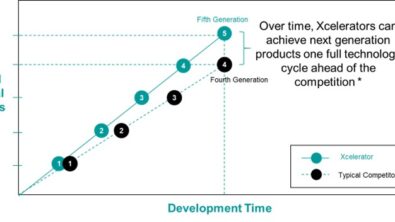

The current reality is that all aerospace suppliers should assess the potential for their products and services to grow in defensible market niches. In support of this they should also evaluate product design and production capabilities and invest in technology solutions to innovate faster, manage costs, and establish a durable competitive advantage for those niches. This will facilitate business expansion, strengthen their position, and potentially dominate the market.

Supply chain digitalization

To support the adoption of new capabilities suppliers are now emphasizing a high level of digitalization for collaboration and co-development in the earliest stages of development. Instead of a purely transactional approach, they are engaging at the beginning of programs, working with primes in the systems design and development phases of specialized products. This “shift left” in the development process helps optimize the supply chain, improves product quality, reduces time-to-market, and enhances cost-efficiency. However, this only truly works in the favor of suppliers if they have enabling digitalization for product design that allows them to interact with the prime in a seamless manner. This requires the capacity to share high fidelity design data as digital twins that are then driven across the development process using specialized workflows as digital threads.

This trend toward digitalization of engineering processes has had a profound impact on the aerospace industry. Prime-supplier relationships are no exception. The implementation of digital tools, such as cloud-based engineering design platforms, data analytics, and virtual collaboration tools, has facilitated real-time communication, streamlined processes, and improved supply chain visibility. These technological advancements enable closer collaboration, efficient inventory management, predictive maintenance, and rapid decision-making, enhancing overall operational performance.

Supplier relationships in aerospace

The changing relationships between primes and suppliers in the aerospace industry reflect a shift towards collaboration, co-development, and mutual value creation. Primes recognize the strategic importance of suppliers and leveraging their expertise to enhance innovation, efficiency, and competitiveness. Suppliers recognize that digitalization has become a critical enabler in fostering successful partnerships. In fact, without a sufficient investment in digitalization suppliers cannot hope to develop the innovative products that preserve competitive advantage, nor can they gain the operational advantages that come from close collaboration with primes. As the aerospace industry continues to evolve, investments in digitalization create strong and collaborative relationships between primes and suppliers essential to drive future growth, ensure resilience, and meet the ever-changing demands of the market.