Lessons Learned: 300 freshmen engineering students learn modeling and assembly in NX CAD

This blog is the second in a series about the Engineering Design Graphics course for freshmen engineering students at the University of Cincinnati. Check out the first blog to learn more about the course, the partnership between Siemens Digital Industries Software and the University of Cincinnati, and some of the Fall 2022 reverse engineering presentations.

As the Spring semester comes to a close, university students pull all-nighters in the library, frantically cram for finals, and anxiously await final presentations. At the University of Cincinnati, 50 teams of freshmen mechanical engineers present their reverse engineering modeling projects that they’ve been working on all semester.

Benefits of learning NX CAD early in college

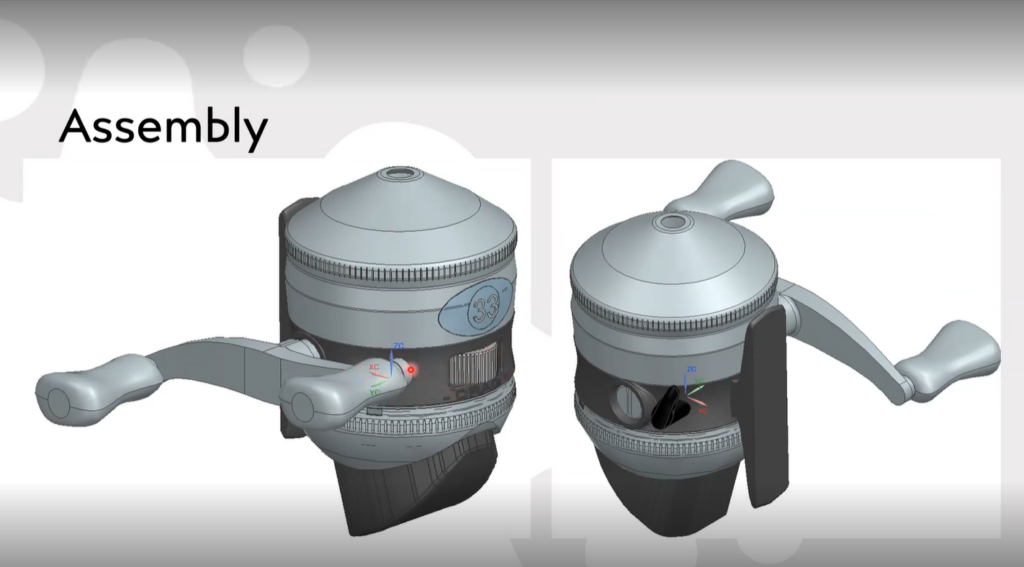

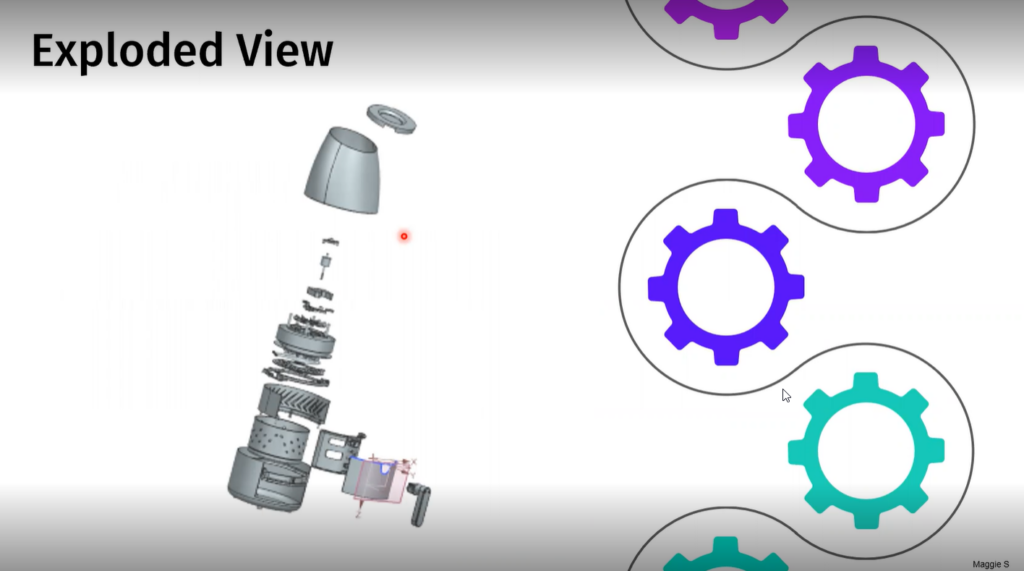

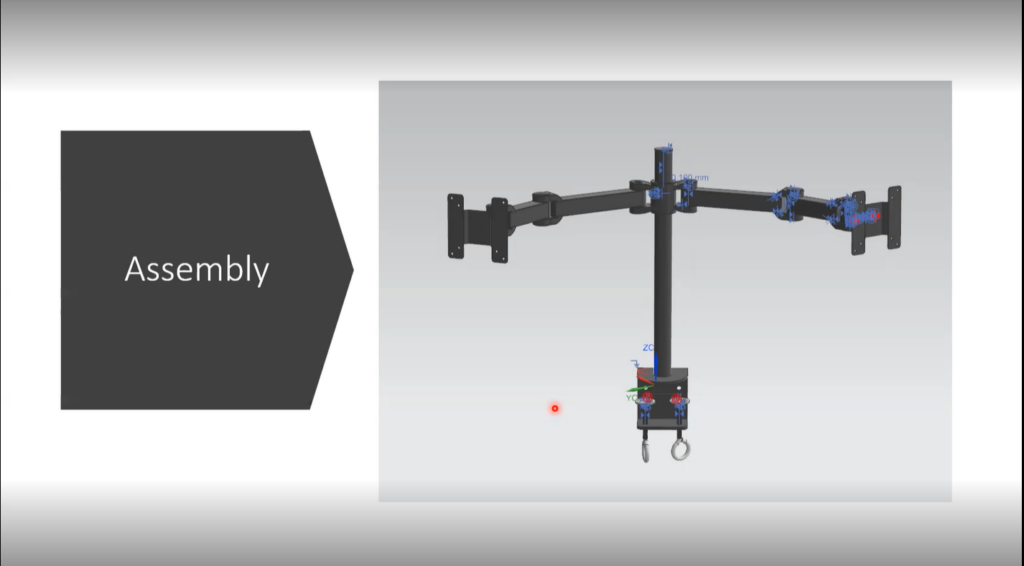

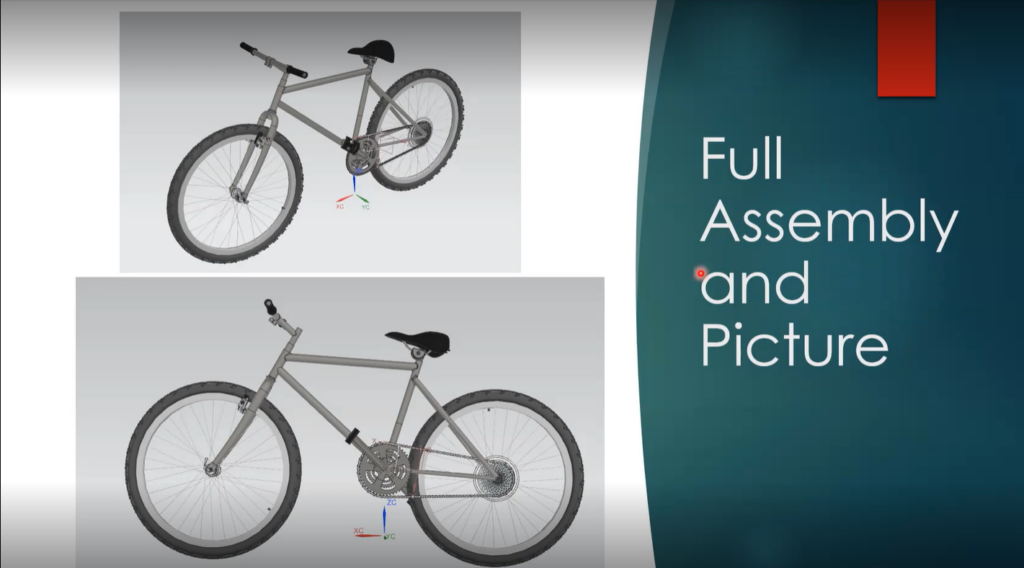

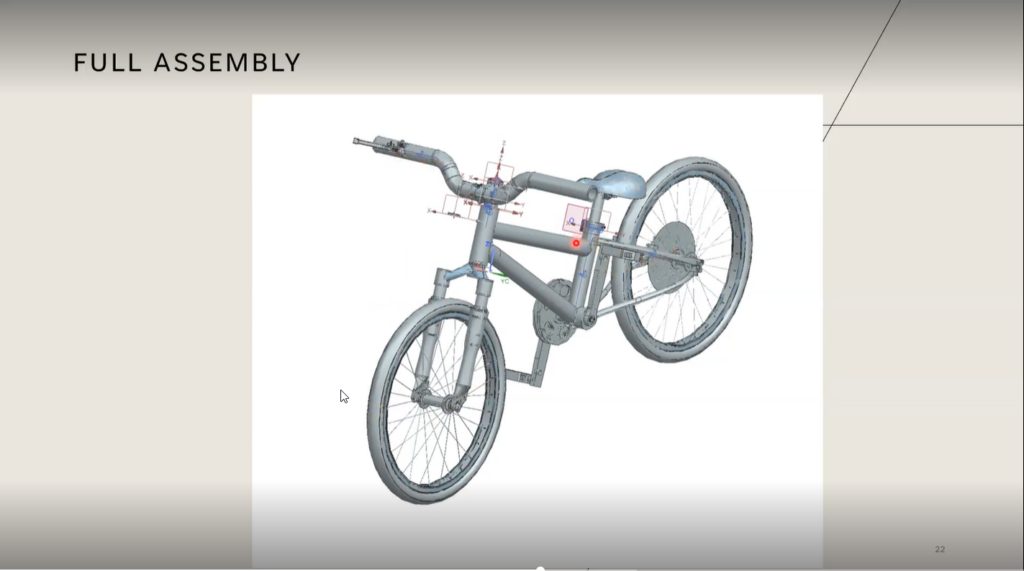

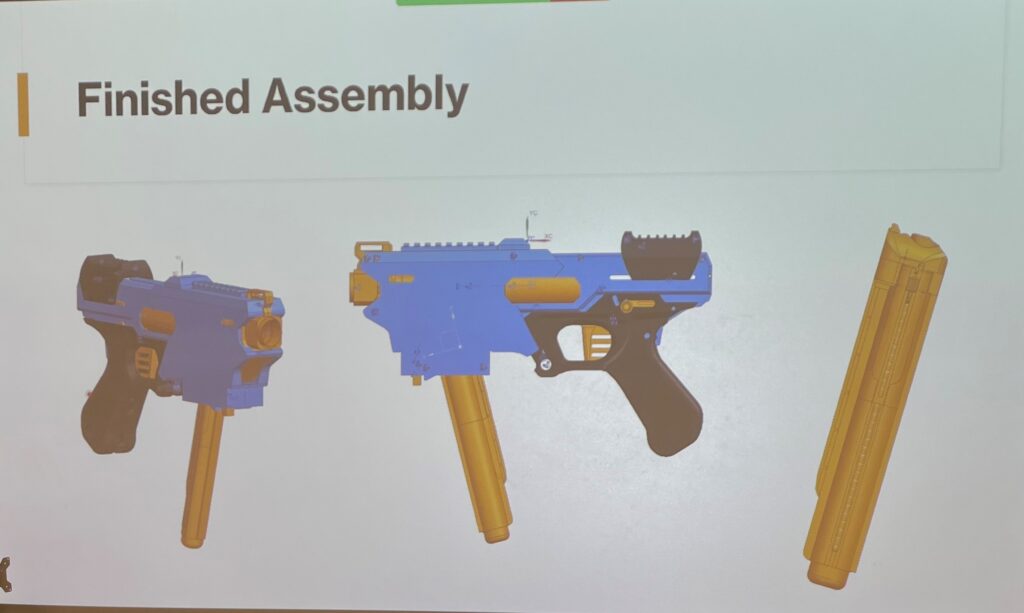

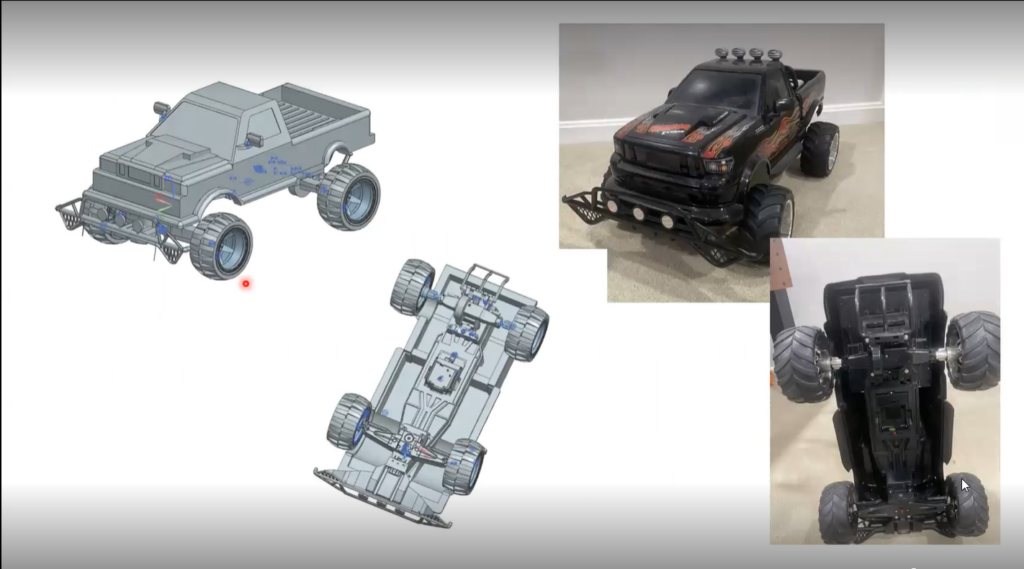

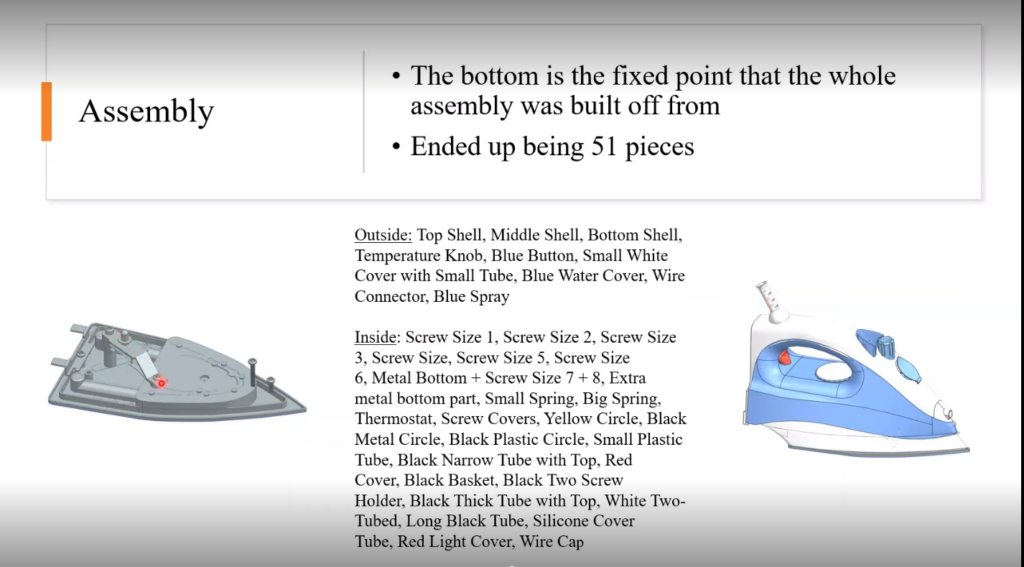

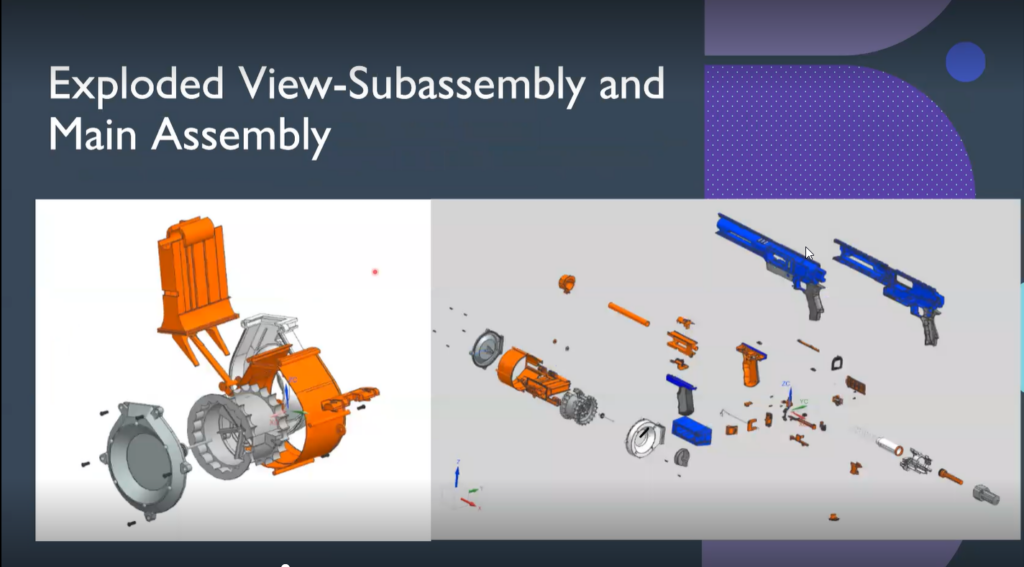

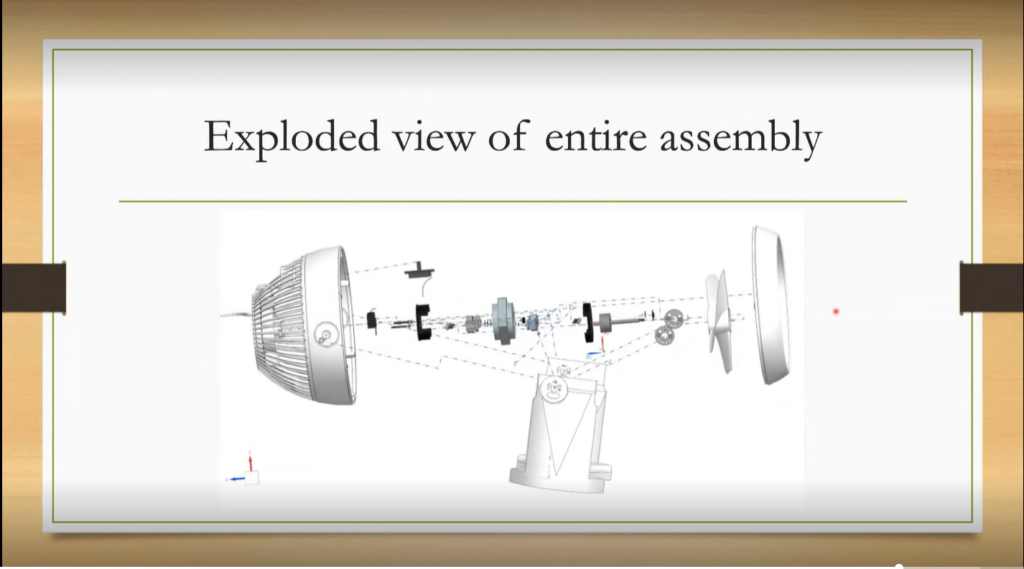

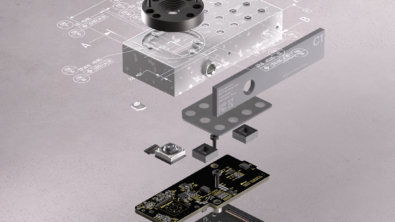

I had the pleasure of visiting UC to see 16 of the 50 presentations. The reverse engineering projects included a fishing reel, air fryer, dual monitor holder, Giant Iguana Bicycle, TREK bike, handheld angular saw, RC car, FORSA desk lamp, Impress clothing iron, Hamilton Beach blender, Honeywell fan, Cozy Couple Model, and four types of NERF guns.

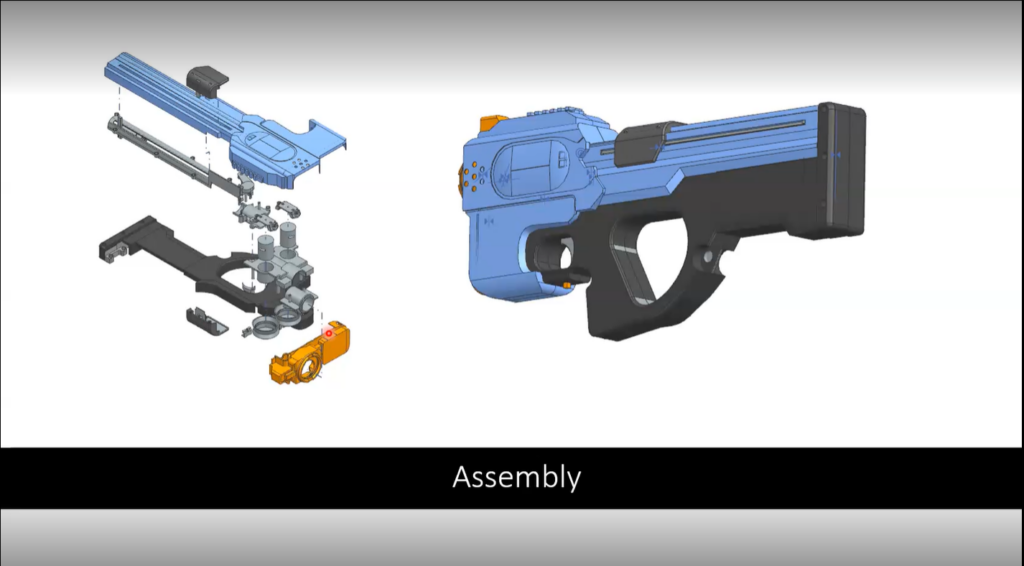

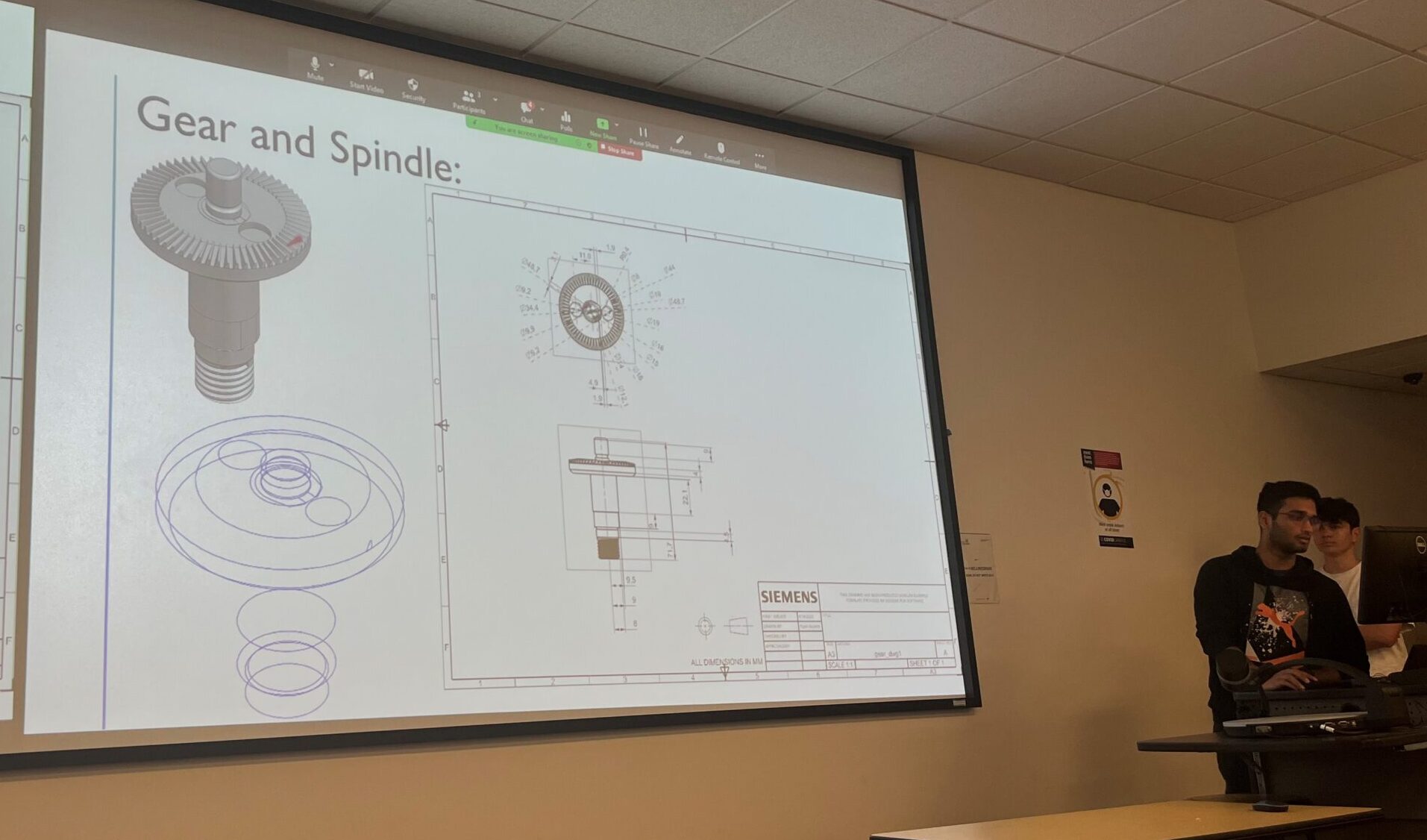

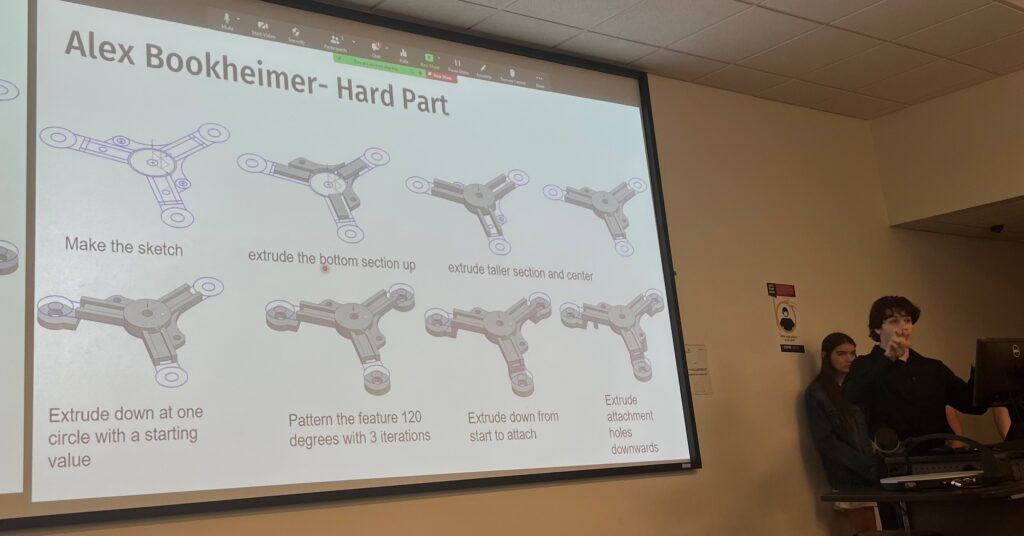

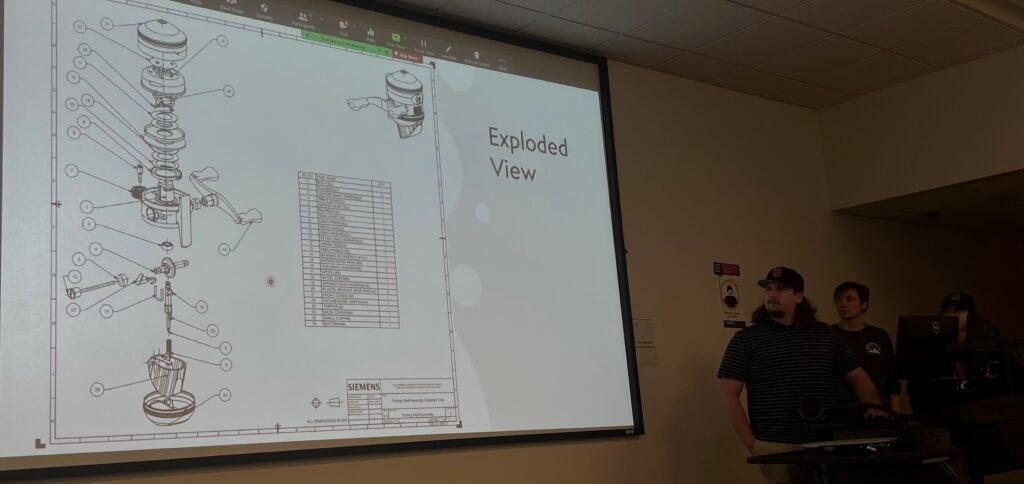

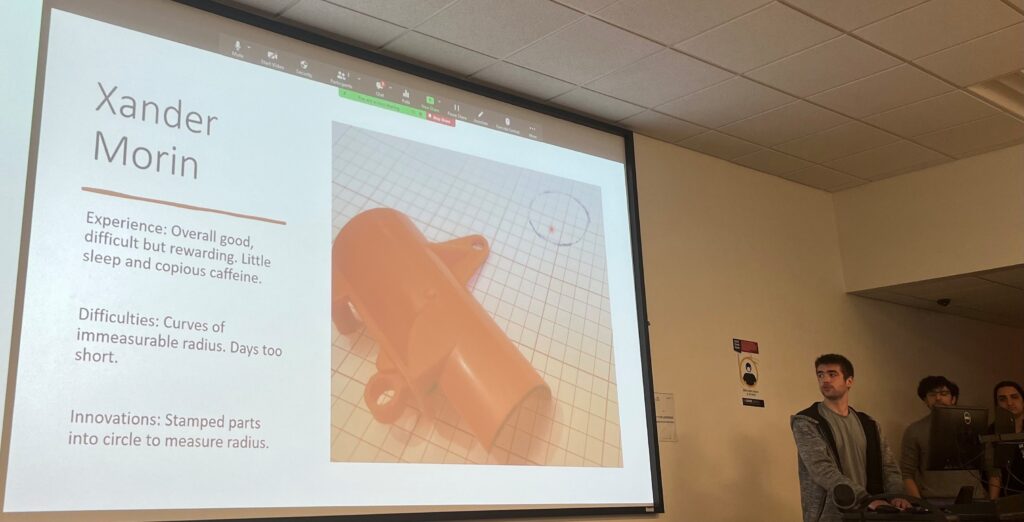

The presentations all follow a specific format. Beginning with an introduction to the team and history about the project, the team then goes through each student’s roles and what parts they created, then each team member presents their most complicated parts and the steps they took to create it along with 2D drawings of the part, then final and exploded assembly is shown. Students conclude with the lessons they learned from the project and using NX CAD, with their words of wisdom for if they or someone else were to repeat the project.

All the students noted the benefit of applying their class learning to a real-world application using NX. For many of the students, it was their first time using a CAD program. Using NX allowed them to “master 2D and 3D modeling,” learn 3D assembly, fix design issues, and step outside of their comfort zone. Beyond the technical skills of using NX, many noted how the project prepared them to work on real-life design projects through learning how to work with a team, problem-solving skills, and project/time management. One team even noted that there is “no such thing as too much communication.”

Engineering students’ lessons learned from NX CAD

Once students had their item approved for the project, they learned what it took to reverse engineer it— getting their hands dirty in breaking down into parts and measuring them with calipers. Some teams noted difficulty in measuring curves or non-rigid surfaces on the real parts, making the modeling process more difficult and requiring some creativity to measure (see below). When it came time to model the parts, they quickly realized how important accurate measurements were, especially with parts with low tolerances, such as small parts or ones that needed to fit into many other parts. While they learned how to iterate on the parts to make them fit in the assembly when needed, students recommended making sure to measure the parts together as a team in the beginning as opposed to dividing their parts and then measuring them as individuals. This would ensure parts would fit together for the final assembly, saving time and reducing rework.

While there were similar sentiments about beginning the project, there were differing opinions amongst the teams for how often they needed to meet with each other, similar to a design review in a real-world project. Some students said weekly meetings were not necessary or that they just needed to meet in the beginning and work individually until it was time to assemble, while others noted that they wished they met more often in the modeling phase to make the assembly phase easier and reduce the need for edits. Regardless, many teams shared the same advice: begin the project with the simpler parts and be sure to save time for assembly at the end. Some teams with more complex items recommended creating multiple subassemblies before the final assembly.

Engineering Design Graphics Spring 2023 – NX CAD reverse engineering projects

Regardless of the hurdles that inevitably come with a group project, students took away many lessons that will prepare them not only for their future courses in which they need to know how to model a product, but also for their co-ops and careers. See below for the projects students presented on April 26, 2023.

Use the arrows to navigate and “Open in new tab” to expand the image.