Characteristic accountability with NX Inspector

First article inspection enabled at the heart of product design

The NX™ software team prides itself on delivering industry leading solutions through our continuous release cycle. With that in mind, we’re proud to announce that a brand new module will be available in our June 2025 release; Introducing NX Inspector. NX Inspector is the first CAD native implementation of the Digital Metrology Standards Consortium and ANSI standard for model based characteristics – integrating data that engineers previously managed across a variety of documents and software tools.

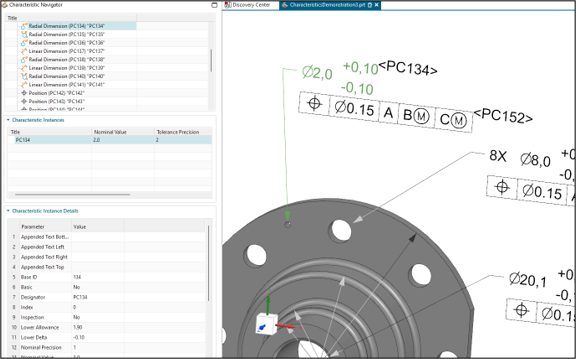

Automated ballooning of characteristics with NX Inspector

NX Inspector authors characteristics directly inside NX and connects to Teamcenter for management across the digital thread for consumption in quality and manufacturing. This connection to design enables traceable first article inspection and allows quality teams to easily identify and trace key characteristics. It’s important to note that characteristics will have criticality definitions and other details that may not be contained in PMI for manufacturing and quality purposes.

Why is it advantageous to use NX Inspector for your characteristic needs? Well, you’ll be optimizing your engineering data for consumption in downstream processes, whilst meeting digital enterprise standard compliance requirements.

These characteristics that are created by NX Inspector follow the Digital Metrology Standards Consortium (DMSC) standard. It’s the first CAD native implementation of the DMSC MBC standard on the market. The result? A first to market model-based approach for defining and consuming engineering data consistently and completely in quality and manufacturing workflows.

Once defined in NX, all characteristics including key characteristics can be leveraged downstream in Siemens’ Teamcenter® software for product lifecycle management (PLM) and Teamcenter Quality for quality assurance (QA) process planning connecting the characteristics digital thread.

Automated ballooning with direct PMI associativity

Our focus with NX Inspector is to ensure you can define characteristic types for your PMI with direct associativity on a familiar platform to you. Support is enabled to balloon characteristics automatically from different PMI types. What’s more, it’s incredibly easy to access new commands from the Characteristics navigator.

Direct associativity between these characteristics and PMI allows for real-time update of characteristics as soon as design changes occur. We’ve also enabled support for NX Open automation, enabling you to customize and tailor specific workflows as needed.

“NX Inspector characterizes product manufacturing information (PMI) to ensure consistent interpretation and consumption of engineering requirements and design data from design to quality and manufacturing. “This offering brings together manufacturing, quality management, and metrology, in a way that should bring promising value those looking to fully embrace a model-based enterprise.”

Michelle Boucher, Vice President Research of Engineering Practices, Tech Clarity

DMSC MBC standard support for key characteristic semantics and display

Ensuring NX Inspector follows the DMSC MBC standard was imperative. It’s a global accreditation to ensure global companies abide by these standards, whilst also encouraging their development and interoperability.

Key support for these standards within NX Inspector covers:

- The occurrence of characterized PMI as per the DMSC standard

- Characteristic augmentation is supported including key characteristics

- Full support for standard compliant symbology

- UUID for enabling characteristic accountability across the entire digital thread

Characteristic support for CAD neutral formats

Flexibility is key when it comes to NX Inspector. So, we’ve enabled functionality so that you can export model-based characteristics to CAD neutral formats. Dependent on your requirements, support is enabled for both QIF workflows and PLMXML export.