Exploring Siemens sustainability strategy with Eryn Devola, Head of Sustainability at Siemens Digital Industries

Welcome to another recap of the Next Generation Design podcast for the episode: Siemens Technology Empowers Engineers to Create Sustainable Products. You can watch the full video version of the episode below.

On this episode of the Next Generation Design podcast, host Greg Arnot welcomes Eryn Devola, the Head of Sustainability for Siemens Digital Industries to talk to us about the various sustainability initiatives underway.

In this episode, you will learn about why we as consumers should care about sustainability, collective intelligence and why the concept of customer zero is so important.

What you’ll learn about in this episode:

Who is Eryn Devola?

We kick off the episode learning about Eryn and her responsibilities as the Head of Sustainability for Siemens Digital Industries (DI). She says that there are three main things she is responsible for within Siemens DI:

- Environmental footprints of operations: Looking at our operations and thinking about impacts with our choices of travel, office spaces, factories, data centers and more.

- Environmental footprints of products: Looking end-to-end at how our products, especially hardware, impact the environment throughout their lifecycle from production through use and disposal.

- Improving our solutions to help customers be more sustainable: Looking our handprint instead of our footprint and thinking about how we can help our industrial customers become more sustainable in their own operations with the solutions that we provide.

Eryn has both a Bachelor’s and Master’s degree in Mechanical Engineering, so we asked how she transitioned into working in sustainability. Eryn notes that many sustainability professionals didn’t study sustainability, they come from different disciplines which helps them to understand how to bring sustainability to their respective fields. “I have always appreciated my engineering education and how that’s given me a great foundation for complex problem-solving and for really understanding multi-factored optimization,” she states.

The shifting trends in sustainability

Many of us care about sustainability on a personal level because we want to leave the planet in a better state for the next generation. When it comes to corporate responsibility though, there is an added business perspective due to limited resources. “We’re currently using 170% of those renewable resources every year. So we’re using 0.7 more Earth’s worth of resources than it generates,” Eryn explains. In order to still have a business in the future, we need to use our resources wisely and think not just about profitability, but sustainability as well.

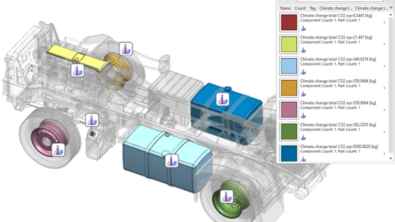

In the past, the major focus has always been on CO2 emissions. However, focuses in industry have been shifting from just CO2 to more broad topics, such as how efficiently we use resources or how we include circularity in products with extended use and reuse of materials. While CO2 is still an important KPI to pay attention to, we have to look at other impacts too like biodiversity, land use, water, rare earth elements and substances of concern.

Helping Siemens customers develop more sustainable products

Eryn says that at Siemens, we need to build sustainability into every decision that we make, and that starts with empowering each person in the company to think about sustainability in each of their decisions, no matter what department they are in. We aim to minimize the footprint impacts and maximize the positive handprint impacts, and we do so through the DEGREE framework.

The DEGREE sustainability framework defines clear goals and actions for our sustainability ambitions:

- Decarbonization: Reducing CO2 footprints for ourselves and our customers

- Ethics: Fostering a culture of trust and adhere to ethical standards for all stakeholders

- Governance: Establishing structures for driving responsible business conduct

- Resource efficiency and circularity: Optimizing and minimizing resource usage and driving longer life cycles

- Equity: Ensuring a fair and diverse environment for employees, business partners and our community

- Employability: Focusing on skills we can give our employees and foster in our communities to drive impact

Within Siemens DI, we also focus on providing our customers with the right tools to enable inclusive, sustainable decision making. One of the key ways we are working to do this at the software level is by adding impact analysis tools to our suite, such as with the award-winning NX Design for Sustainability module (we talked more about this module on our previous episode with Nexpirit, our development partner, and Phoenix Contact).

We are committed to helping startups who have new ideas around sustainability. With our Siemens Xcelerator marketplace and our as-a-service models, we can get tools and technology into the hands of smaller companies as we reduce the cost barrier that may have been limited to only larger companies in the past. For example, companies like Regent and Ekonoke leverage and scale Siemens technology for sustainable coastal travel and controlled environment agriculture, respectively.

Defining collective intelligence, customer zero, collaboration networks, circular economy and shifting left

Throughout the episode, we hear Eryn and Greg discuss few terms like collective intelligence, customer zero, collaboration networks, the circular economy, and shifting left. Eryn helps us to understand what exactly these terms mean in context of sustainability at Siemens.

Collective intelligence

Eryn thinks about collective intelligence as the way we bring together knowledge. We need to share knowledge across the value chain, from from manufacturers to everyone within the supply chain and within distribution networks in order to get a complete picture of impacts and thus optimize along the value chain. She brings up an example with Procter & Gamble, as they looked at the entire environmental impact of a load of laundry as opposed to just the detergents that they make, and found that heating water for laundry used the most energy, so they optimized their detergent to work in colder water.

Collaboration networks

Collaboration networks are an important part of driving collective intelligence, and Eryn goes over a few examples, Catena-X is an organization for the automotive industry which focuses on having consistent standards (such as for how the industry measures CO2) and collaborating across OEMs and supply chains. Together for Sustainability (TfS) for the chemical industry is another collaboration network that are also focused on having a common exchange of data to have more transparency that allow us to make decisions for sustainability. Siemens is also a member of the Green Software Foundation, an organization similar to the previous two but for software, especially focused on reduction of greenhouse gases.

Customer zero

Greg explains that this concept refers to an organization being both the first and leading customer of its own products and services. Eryn expands on the concept of whether we are customer zero for sustainability, saying that in some places we are, but in other places we learn from those that came before us.

For example, the embedded NX Design for Sustainability module was innovative and the first-of-its-kind to help design engineers make decisions based on sustainability. However we also learn a lot from our technology partners. We all have to learn and collaborate together with other companies, as “You have to think about it from the end of a value chain as the start of the next value chain.”

Shifting left

To “shift left” means to move something earlier in the process. For sustainable product design, this means looking at the environmental impacts of a product’s design, materials, etc. before it is ever produced and on the market. It is not looking at products that have already been made and thinking about what we can change to make it more sustainable— because when we need to make changes later to a design, we also need to change machinery, manufacturing processes or even the manufacturing building. It means focusing on optimization and making sustainable decisions early in the design process, before the product is ever produced.

The circular economy and the circular design method

Eryn says that the circular economy means “thinking about materials and business models in a way that extends life cycles and creates a circle rather than a linear approach.” With a linear approach, we take materials, turn them into a product and then dispose the product (and thus its materials) at the end of the product’s life. So, with a circular approach, we focus on using the product for as long as possible and also think about what will be done with it once the original is no longer usable. We think about how we will repurpose, repair or retrofit the materials, or any way that we can give a product/materials a second lifecycle or purpose. Simply, it focuses on reuse instead of disposal so that we don’t have to continue taking from the earth, we can just continually reuse what has already been extracted.

In the product design and lifecycle management process, we go from thinking about not just how a product will be produced and used, but also about a product’s end-of-life, how it can be retrofitted, what materials can be used for reuse or processing, etc.

Siemens’ strategy to ensure sustainability is a focus in academic engineering education

Investing in academics is incredibly important to ensure that sustainability is a focus for the next generation of engineers. One example of how we are interacting with the academic sector is the work we have done with the University of Colorado, Boulder to put out a Coursea course based on the circular economy. This course helps engineers to expand their knowledge on sustainability and circularity.

Greg also asks about what we are looking for in new hires in order to help us meet our sustainability goals. Eryn states that it is important for us to seek out new hires that have a growth mindset and commitment to being a life-long learner, since sustainability is always growing and changing. We also look for people who can manage complexity and ambiguity, since we don’t have all the answers yet and everything continues to evolve.

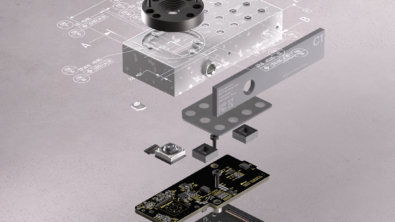

How the digital twin can help companies meet sustainability requirements

We then start to delve more specifically into the realm of product design and the software side of Siemens Digital Industries. Greg asks how digital twins can help companies be more sustainable, and Eryn notes that comprehensive digital twins allow you to optimize without using any physical resources, so you can do most of your testing in the virtual world, which is both faster and better for the environment. Additionally, digital twin technology gives us the freedom to be more creative in the design process since it doesn’t cost as much or take as long to try different iterations, like it would with physical prototypes.

When asked if engineers should focus on creating more sustainable products, Eryn says that she thinks they have to be in order to have a future-proof product that meets all requirements, given the increase in legislation and required disclosures for environmental impact of products. Engineers should strongly consider their upstream or supply chain, as it is most often the biggest contributor for a product’s carbon footprint. We all have to work together across the value chain in order to get the data needed for this kind of decision making, as well as how to communicate and share data openly, consistently and with standardization. It is also important to partner with other businesses who share similar values and goals regarding sustainability within their own organizations.

Eryn believes that we, as a technology company in the PLM space, can play a big role in maximizing sustainability in products since 80% of the environmental impacts of a product are determined during the realization or design process. Within our design software, we can empower engineers to make data-driven decisions that are more sustainable.

With that being said, Eryn shares a few things she would look for in a CAD or product design software as someone with a mechanical engineering background. She wants to be able to see the environmental impacts of materials—with material selection itself and amount needed for the product. She wants to be able to compare impacts of choosing different materials, such as one that may be similar in cost and performance but with a lower environmental footprint. With NX CAD, we offer the ability to run these types of analyses, “Being a design engineer is not getting easier, that’s for certain,” she begins, “but I think our tools are also getting better at the same time. So, we’re adding layers of complexity but also giving additional insights to help make those tough decisions.”

NX Design for Sustainability

CAD software gives us the ability to see impacts early in the design process, helping us shift left. NX Design for Sustainability (mentioned in the episode as NX Sustainability Impact Analysis) is a module within NX CAD that allows you to look at the environmental impacts of selecting certain materials as well as include environmental KPIs/targets as part of your requirements for your designs. As you join components together and create sub-assemblies, you can see how your design choices impact that target and look at 14 different environmental KPIs (not just CO2)!

We conclude the episode discussing predictions and vision for the future. Eryn expects regulations to become less ambiguous, more standardized and generally more prevalent as we see the effects of climate change and overconsumption of Earth’s resources. As for her future vision, she wants to see every person weigh sustainability as part of their decision making, whether it’s during their own purchasing, designing a product or even deciding how or where to travel.

At Siemens, we can play a role in achieving that vision as we help people in the industrial sector understand not only performance and cost impacts of their choices, but the sustainability impacts as well. Through our solutions, we enable and empower our customers to make data-driven decisions for their own products and solutions with the environment in mind.

Continue listening to the Next Generation Design podcast.

Want to learn more about NX CAD software? Check out our website or try it for free.