Mastering medical device design: 3 critical components for success

The medical device product design cycle is meant to be connected and related — and maintained that way — but traditional approaches have not reliably captured the connections.

Inventing or improving product design is a multidisciplinary, time-consuming process that requires precise coordination to ensure robust prototypes and timely project phase launches. But communication breakdowns can upend even the best of product ideas.

This isn’t an abstract. Real-world medical device design problems continue to cause real-world product recalls. Here’s one recent example:

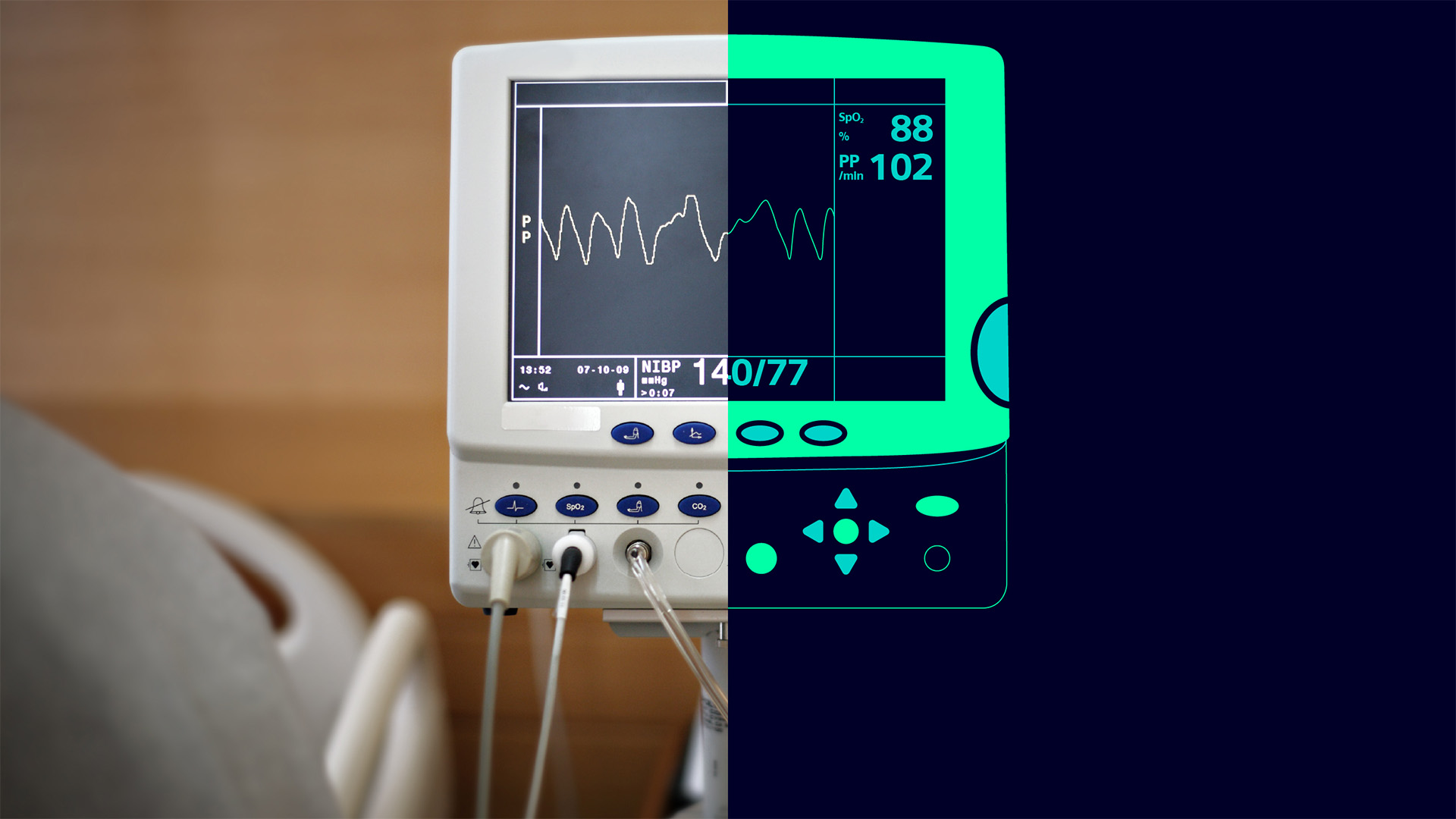

A clinical platform device that monitors surgical patients’ blood pressure and pulse was found to trigger an electrical short if fluids leaked into the power outlet causing the device to malfunction or catch fire. This design flaw created a risk of serious injury or death to patients and healthcare professionals. Could this design disconnect have been avoided?

With so much at stake, the design phase becomes a linchpin for the successful development of efficient, accessible and compliant products.

So how can manufacturers create robust and innovative medical device product designs quicker with no compromise on quality?

A new era for medical device design development

To efficiently improve medical device product design, it is crucial to digitize the process by using comprehensive, powerful software to model and simulate intelligent mockups, to enhance collaboration between engineering departments and to track necessary documents.

You must be able to use a digital replica of your systems and evaluate performance rapidly to meet all requirements and make the best possible design decisions in the shortest amount of time.

Siemens Design Excellence for Medical Devices solutions empower design teams with the capabilities to create efficient, high-performing, fully compliant product design through an integrated digital system backbone. That means companies can implement a connected platform to achieve competitively differentiated, innovative and safe devices.

Our Design Excellence tools enable medical device manufacturers to improve design software processes through three essential elements:

- Comprehensive virtual product design (aka digital twin)

- Collaborative design development

- Traceable design process

Watch Design Excellence for Medical Devices video

1. Rapidly build a complete digital twin of the device

Comprehensive virtual product design tools for mechanical and electrical systems help conquer complexity with advanced functionality to meet medical device development needs, including:

- Mechanical product design

- Electrical system design

- Electronic system design

The Siemens Xcelerator portfolio provides an integrated suite of applications for developing 3D digital twins in a flexible and efficient environment. Users can quicky build precise product models for visualizing, sharing and confirming medical device product designs.

Digital twin technology enables faster design of new components and design changes, helps users design and route wire harnesses in complex assemblies, and generates 3D assembly models of flexible printed circuits or rigid PCBs and components.

2. Empower disparate teams to work together

Collaborative medical device development enables disparate teams working on specific disciplines to design collaboratively, so that project alignment can be enhanced and possible design-change errors can be identified and fixed earlier.

Siemens collaborative design development tools reduce or eliminate physical prototypes in the early project phase using digital mockups to explore design options and optimize devices. They enable users to find and resolve form-fit-function design issues with sophisticated spatial analysis.

The tools provide a complete solution that takes advantage of data without having to re-master it in another system. Everyone can view the same model and review, discuss and provide feedback in real time.

3. Digitally manage all medical device product design data

A traceable design process for design data that is required in your technical files helps simplify product compliance and accelerate market submission. Siemens traceable design process tools give medical device manufacturers a hub for design document and data management. An end-to-end labeling and unique device identifier (UDI) tool eliminates process and data redundancies through digital control across applications and departments.

Curious to learn more about labeling and UDI? Check out our on-demand webinar, The challenge of labeling & UDI for medical devices.

A traceable medical device design process helps users:

- Quickly find the right design and regulatory information

- Synchronize global design chain with device history file (DHF)/device master record (DMR)

- Bring design data into context with labeling domain through LMS integration

- Ensure design info is connected to quality processes

Discover more about our medical device design development tools

Siemens Design Excellence for Medical Devices tools can provide faster, streamlined design capabilities in addition to collaboration methodologies that are in high demand. Let us show you how to get started driving design development through integration.

Comments

Leave a Reply

You must be logged in to post a comment.

Understand NURS FPX 4900 Assessment

The NURS FPX 4900 assessment are the cornerstone of your development as a nursing leader, focusing on the synthesis of your learning to tackle complex healthcare issues. Starting with NURS FPX 4900 Assessment 1, each evaluation tests your readiness to lead in the dynamic field of nursing. Need online assignment writing or help with psychology assignment? We offer resources to make each assessment manageable. https://experttutors.info/nurs-fpx4900-assessment-1/