What is Design Excellence for Orthopedic & Dental Services?

Introduction to Design Excellence

What do you think of when you hear the term design excellence? It could mean a myriad of things – better ortho and dental designs, easier design processes, and the standard of care that you hold yourself to when creating medical devices. At its core, design excellence is digital innovation that enables smart, interconnected devices to treat patients more effectively. The key to success is a multidisciplinary system that integrates hardware, electronics, software and formulated components to give companies a competitive edge when it comes to designing ortho and dental devices

Learn more about the five core components of Design Excellence here.

Safety First

When it comes to the design and development of orthopedic and dental devices, nothing is more important than safety. After all, many of these products can stay in a patient for years and years. Engineers are tasked with creating products that physicians can rely on. They need to know early on how a prototype may perform in order to adapt and get the best design quickly.

Learn why shifting requirements and design data into a single digital platform can help your company select a final design faster.

Compliant and competitive

Remove paper-intensive operations and improve compliance data availability by cutting the time it takes to retrieve data from months to seconds. Companies that create orthopedic and dental equipment have little choice but to work smarter as medical device rules require greater control, visibility, responsibility, and traceability.

Moving away from manual processes and toward a complete digital design platform makes compliance much easier to achieve. People from various departments may produce, manage, share, and trace documents thanks to this forward-thinking approach.

This one source of information can assist deliver goods to the market faster by lowering approval wait times, in addition to boosting organizational collaboration and safety.

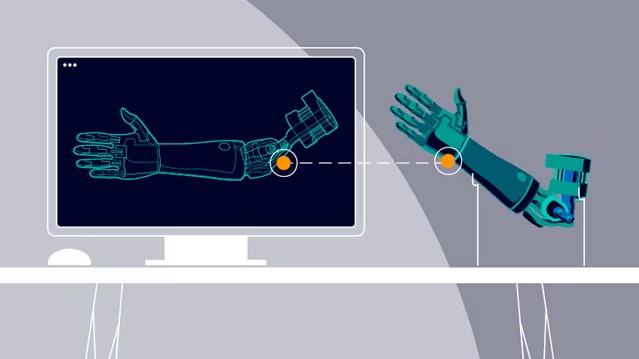

Confidence in complexity

Increased complexity requires multidisciplinary teams to come together to solve challenges around every detail – from batteries to high-voltage wires and sensors. A single software solution that spans design disciplines can transform the design process, helping to reduce time to market and costs.

Through simulation and the use of a “digital twin”, engineers can test and tweak the finest details of a product with incredible accuracy based on real-world conditions. This means any issues can be resolved quickly without holding up development.

Integrate to innovate

It is an exciting time for designers of orthopedic and dental devices. Technology is bringing ideas to life on an unprecedented scale. Now is the time to integrate a digital platform that contains concurrent design tools that is scalable, connected and collaborative. Companies need a platform to integrate mechanical, electrical and software elements as well as product lifecycle management.

A platform like this will reduce costs and raise team efficiency, which means products can hit the market faster and with more innovative features.

Align for excellence in the ortho and dental industries

It can be very tempting for individual departments to pile resources into workflow-specific tools and solutions. However, this is a siloed effect that can have the opposite reaction that teams are hoping for when it comes to solving challenges.

Clear organization alignment is critical. When each team across the product development process collaborates around a single source of information, they can innovate at speed. This means fewer mistakes, simplified communication and smarter decisions. A suite of collaborative design management software tools and a common hub of stored information enable parallel design activities and easier auditability.

Get *joint*-up thinking and tackle complexity in orthopedic and dental device innovation.