Discover better designs faster: Simulation and design exploration in MD&P

The life sciences sector – primarily the medical device and pharmaceutical (MD&P) industries – is experiencing an unprecedented change in the way new medicines and medical technologies are being created. Leading health care companies are using modeling and simulation to reduce costs, mitigate risks and increase innovation. Ultimately, this results in better medicine, superior medical devices and improved outcomes for patients.

The shift to simulation-based product development

One big shift in recent years has been that simulation-based product development and virtual prototyping are being recognized by the FDA as valid tools to supplement experimental testing and clinical trials, where deemed appropriate. This shift means that regulatory approval can be accelerated to get products and medicine to market quicker.

Initiatives, such as the ASME V&V 40, MDIC or Avicenna, are driving and guiding these efforts for increased use of simulation for the support of benchtop and clinical trials in the medical device industry. Similarly, in the pharmaceutical industry, the move from batch to continuous manufacturing is being promoted by consortia like CSOPS. This shift in the industry presents an opportunity to integrate simulation early when redesigning processes, offering the best chance of maximizing a company’s return on investment.

Read on to learn more about specific companies that are using simulation to advance the health care field in different ways.

Matters of the heart: The role of simulation in saving lives

Congenital heart defects are the most common type of birth defect, affecting nearly 40,000 children every year in the United States. Congenital heart disease (CHD) is responsible for more deaths in the first year of life than any other birth defect. CHD involves defects in the structure of the heart, including the walls, veins, arteries and valves. With no known cause, it is paramount to understand the effects of the disease to fight against it. This is exactly what a group in Florida is doing.

The Mechanical and Aerospace Engineering Department at the University of Central Florida is pushing the boundaries of numerical simulation to new frontiers to better understand and investigate potential improvements of surgical techniques for pediatric congenital heart diseases. The team collaborated with Dr. Alain Kassab and Dr. William DeCampli of The Heart Center at Arnold Palmer Hospital for Children and the American Heart Association. These groups came together to understand the complex global and local hemodynamics of Hybrid Norwood (HN) circulation.

Learn more about the use of numerical simulation to assist in understanding the effects of a reverse Blalock-Taussig (BT) shunt and the resulting anomalous flow patterns.

Blood flow simulation brings safer and affordable hemodialysis

Chronic kidney disease (CKD) is a large public health issue, affecting more than 8 percent of the global population. The most severe stage of CKD is end-stage kidney disease (ESKD), which results in total failure of the kidneys and requires dialysis or a transplant to live. More than two million people are currently receiving dialysis treatment worldwide.

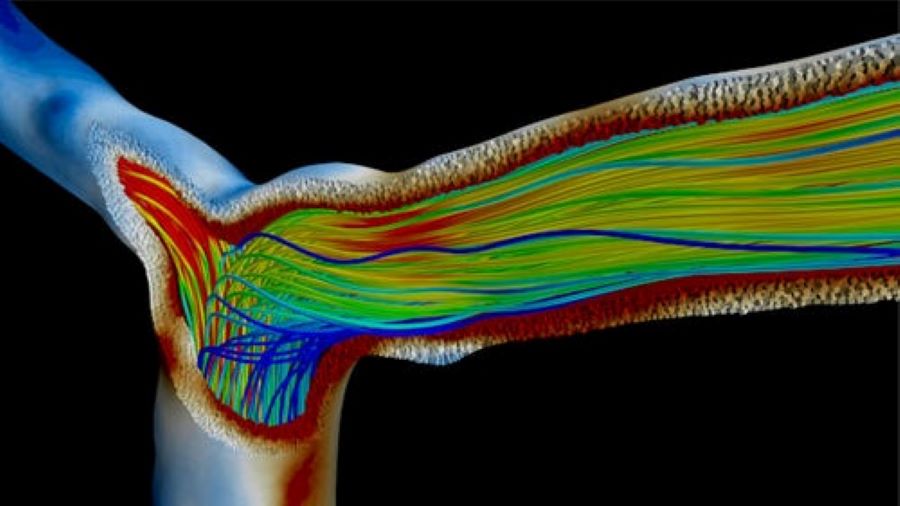

Hemodialysis removes blood from the body and runs it through a special filter to eliminate the unwanted substances and then pumps the blood back into the body. The key requirement for hemodialysis is to draw the blood from inside the body, using access from a catheter or a connection between the arteries and veins, known as an arterio-venous fistula (AVF).

In recent years, computational fluid dynamics (CFD) – a numerical simulation technology first developed for aerospace applications, has become a popular design tool. The research team at Imperial College London used numerical simulation to analyze multiple AVF configurations. They wanted to understand the impact of the geometry of blood flow patterns and the likelihood of failure. CFD allowed the study of blood flow in the vasculature and enabled researchers to properly visualize the complex flow in greater detail while remaining non-invasive.

Learn more

Learn more about the simulation process and read how other companies used simulation in the life sciences sector. Contents of the ebook include, and more:

- Knowledge-based virtual process to aid abdominal aortic aneurysm diagnosis

- Numerical simulations for continuous manufacturing of active pharmaceutical ingredients

- Numerical simulations for tableting and coating

- Something to smile about: Using simulation to improve dental implants

- When CFD secures the manufacturing process of vaccines