Electric heavy equipment: Keys to efficiently designing alternative powertrains

The race towards designing and manufacturing electric heavy equipment is well underway, with most large enterprises adapting business models and engineering structures to accommodate a variety of alternative fuel sources. Comparing electric architectures and establishing the best electric powertrain technology is a key step in ensuring success. In addition, defining how your teams can support the electrified components integration and machine overall performance validation.

Simulation allows manufacturers to compare electric architectures based on newly defined technology and determine if a full electric or hybrid version meets the flexibility needs of the customer.

Once a common direction is defined, system simulation can be used to perform component sizing and cascade down requirements for each component. This also eases the collaboration with suppliers – another consideration companies must include in their digital transformation.

Below are several resources detailing how heavy equipment manufacturers can tackle the growing complexity associated with electric heavy equipment technologies:

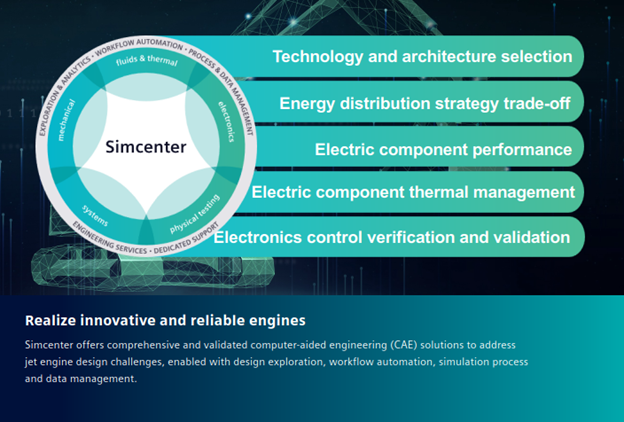

Infographic: Selecting the best electric architecture for your machine

This infographic summarizes the retrofit technology for EV conversions and selects the best electric architecture for your machines. Accelerate innovation, unlock data and enable collaboration with a comprehensive simulation and testing portfolio. Below is a small portion of the full infographic:

Case study: First time right prototype

Check out the short video below or read details about the case study in the link above to discover how a construction machinery manufacturer developed the first electric wheeled excavator using powerful simulation and testing tools.

Case study: 20 to 40 percent fuel savings and reduced operating costs

See the details about how an off-highway supplier was able to reduce modification evaluation time from several weeks to just one day.

Blog: Simulating electric heavy equipment with confidence

Read this blog to learn:

- Why comparing various electric architectures to identify the best electric powertrain technology is so important for success

- What the first step is in the product development cycle

- How to identify the best technology to invest in

Blog: Converting a conventional lift truck into an electric truck

Finally, this blog provides detail about how a global Siemens customer maintained its position as the market leader in heavy forklift machinery by converting its machines from fuel-powered to fully electric versions. Some key details you can learn by reading the blog include:

- How the manufacturer’s team was able to virtually explore and validate their electric machine concept

- Development of the energy recovery system on load lowering

- How the company was able to simulate, analyze and adjust the truck systems in a very short time frame

Master the engineering complexity of electric heavy equipment with an integrated solution

Before a piece of equipment is built, engineers need to perform simulation to analyze new machine architecture efficiency. In addition, testing enables a machine in operation to capture data and feed it back to existing models to improve the next generation of heavy equipment. Some of the key benefits of using simulation and testing for heavy equipment include:

- Making the correct decisions on electric heavy equipment from the start

- Deploying a model-based approach to support advanced controls development and validation

- Optimizing performance attributes and finding the best comprise to fit both regulations and market requirements

Learn more today about tackling your electric heavy equipment challenges with Simcenter. Click below to start a free simulation trial today:

Dive into additional heavy equipment simulation use cases

This blog is part of a series addressing specific challenges with heavy equipment design and how simulation and testing software can help OEMs tackle complexity. Click below to explore additional use cases:

Durability and structural analysis

Access additional resources about electric heavy equipment solutions below:

Resource guide: Predict heavy equipment performance

On-demand webinar: Transition Heavy Equipment to Hybrid, Electric, or Hydrogen Powertrains

Ebook: Additional simulation success stories from heavy equipment manufacturers

Blog: Heavy equipment electrification re-inventing the industry

Talk to a Siemens expert today about electric heavy equipment solutions