Three vital considerations for updating and migrating SMT engineering software

Software maintenance and upgrades are critical for surface mount technology (SMT) manufacturing solutions. Information technology (IT) teams may keep older software off networks to prevent security vulnerabilities. Machine software can be challenging to update, leading to workaround inefficiencies that increase with additional workarounds. In addition, sometimes it is necessary to migrate to new-generation software to keep current solutions active or reap more benefits.

Mitigate software update challenges by adopting the right strategy. Before making any migration decision, teams should review three considerations to ensure the success of current and future solutions in the manufacturing environment.

1. Impacts of the IT infrastructure on software management strategies

From operating system upkeep to network security, information technology (IT) teams manage a large framework of connected systems and devices. In modern enterprises, everything is connected from accounting systems at headquarters to the computing devices on the shop floor. IT is the gatekeeper of the network balancing budget, software versions, and connections to the corporate network based on vulnerability or other risk factors. Understanding this dynamic and the current infrastructure is essential to building a migration and upgrade strategy.

2. Manufacturing operations and PPP – personnel, process, and productivity issues

Looking deeper into manufacturing operations via a factory audit may reveal that several employees are performing similar tasks using the same data. Worse yet – two people are using different data to program part of an SMT line.

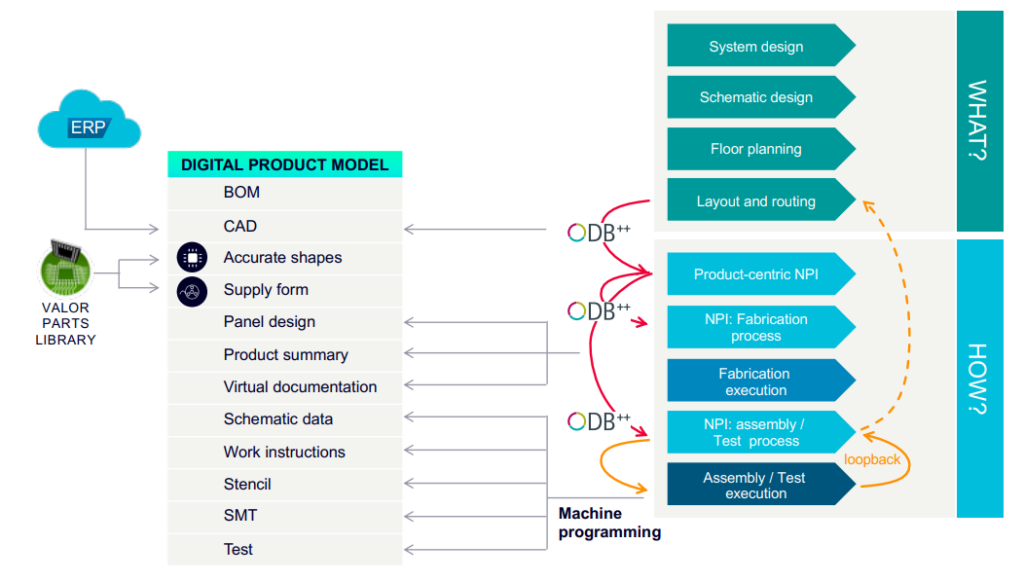

If new solutions or software are introduced but must fit an existing process, the potential of the new solution isn’t fully realized. Reviewing the existing practices, determining where they can be optimized, and then developing new practices built around the capabilities of the new software will ultimately lead to higher productivity improvements. Viewing the factory as a highly integrated ecosystem allows decision-makers to implement solutions with new processes, taking the overall added value to new heights.

3. The unfortunate financial implications of free machine software

Machine-specific software is often supplied free of charge. But free software can have a negative impact on production costs and profitability due to:

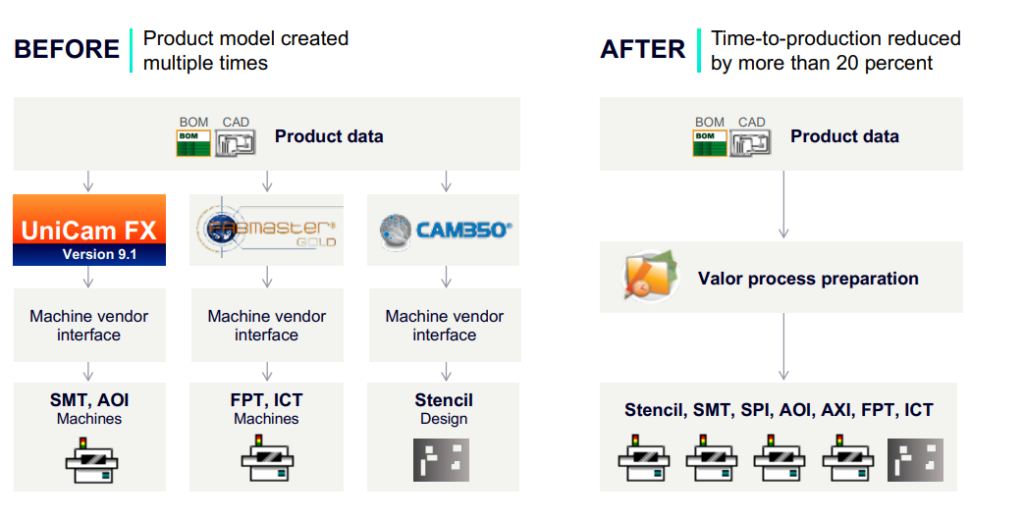

- Duplication of effort

- Data inconsistencies

- Lack of interfaces to other machines or vendors

Most machine software processes input data in a different way, using different files as a starting point, making them likely to produce different results.

Read the whitepaper to learn more about these factors and how Siemen’s single-tool helps to eliminate the challenges of machine-specific software updates and migrations by widening the scope and providing complete orchestration of lines, sites and multisite operations.