Seamless collaboration across disciplines demands smart semiconductor manufacturing (Part 3 of 3)

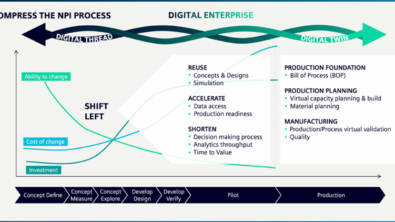

In our first and second posts, we talked about shifting left for smart manufacturing and smart semiconductor manufacturing with real-time reporting and analytics. The final post in our series talks about how the evolution to Smart Manufacturing is essential for competing in today’s rapidly changing global ecosystem where geopolitical shifts, changing customer needs and supply chain disruptions demand adaptive systems and accelerated time to market.

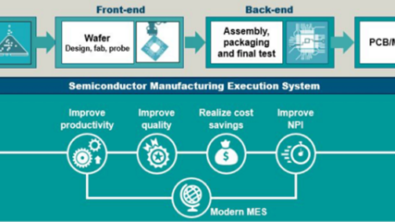

Smart manufacturing built for the semiconductor industry

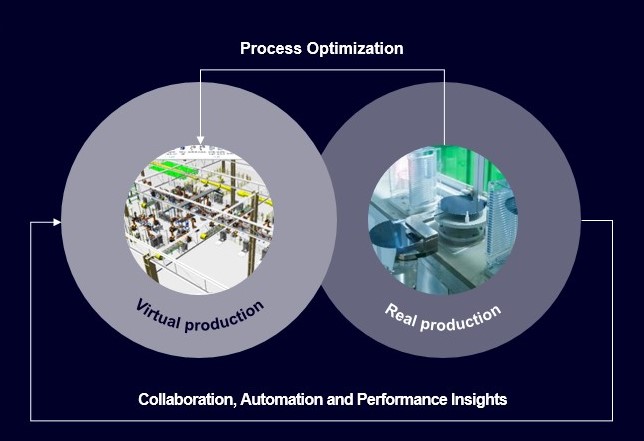

Smart Manufacturing provides the digitalization needed for key stakeholders to manage change flawlessly with seamless collaboration from virtual to actual, combining advanced simulation with digital twins, execution control and real-time reporting and analytics for the continuous optimization of a make-it-right-the-first-time, high yield semiconductor manufacturing process. With closed loop feedback for continuous learning and improvement, you can make MES adjustments, adopt AI, and become fully preventive to mitigate risk, increase NPI yields and compete at the speed of business today.

Manage semiconductor manufacturing changes brilliantly

When virtual simulation and real-time production data come together in one integrated digital platform, it multiplies the effectiveness of your decision-making downstream with seamless collaboration and flawless execution across all disciplines. With a real-time view of all data from design through production across your entire semiconductor manufacturing operation, you can make informed, timely decisions based on real-time insights from semiconductor structured reports. With complete transparency, you can shift left to catch quality issues early, reduce scrap, and make ongoing adjustments to ensure flawless product consistency.

Gain real-time semiconductor manufacturing agility and predictive foresight:

• Easily and seamlessly collaborate across all disciplines involved in any program or task with a robust data management and workflow platform

• Prevent downtime with predictive maintenance capabilities. By analyzing sensor data from your plant and equipment, Siemens tools can anticipate potential problems and schedule maintenance before they disrupt your production flow

• Stay ahead of potential process, timeline and resource disruptions

• Extend the reach of your virtual design and planning into manufacturing execution, activate quality management and engage your supply chain

• Gain foresight on forthcoming engineering changes, process change notices (PCNs), experimental R&D runs, and more

As today’s semiconductor manufacturing conditions and processes change, get ready to manage change rapidly with a continuous stream of data for seamless collaboration and manufacturing execution across your enterprise, across your plants, and across every business, engineering and manufacturing discipline.

The best decisions are data-driven

Data usage is significantly improved with real-time reporting and analytics structured for semiconductor business applications and displayed in the right context for semiconductor processes and products. Your team needs an end-to-end digital solution that connects the essential data so you can collaborate seamlessly across the virtual and the actual world.

It begins with a smart manufacturing solution that digitally connects all the design, engineering and production disciplines, systems and departments for each of your manufacturing plants, lines and cells. It includes Enterprise Resource Planning (ERP), utilities, Semiconductor Equipment Manufacturers (SEM), quality management systems (QMS), and even extends across your global supply chain.

With our end-to-end solution, you are equipped to improve continually, while producing at the speed of business today. You can collaborate seamlessly with a secure, open platform that connects all manufacturing solutions and data within your enterprise and across your supply chain to enable the highest levels of initial quality to deliver designs that are right when built the first time.

Want to launch a continuous data stream with seamless collaboration for smarter decisions across engineering, manufacturing and business disciplines?

Explore how seamless collaboration can drive your semiconductor success in our compelling eBook: siemens/seamless-collaboration-e-book-pdf.pdf

Or discover additional insights at smart manufacturing for semiconductors

Blog co-authored by Melville Bryant, Siemens Digital Industries Software