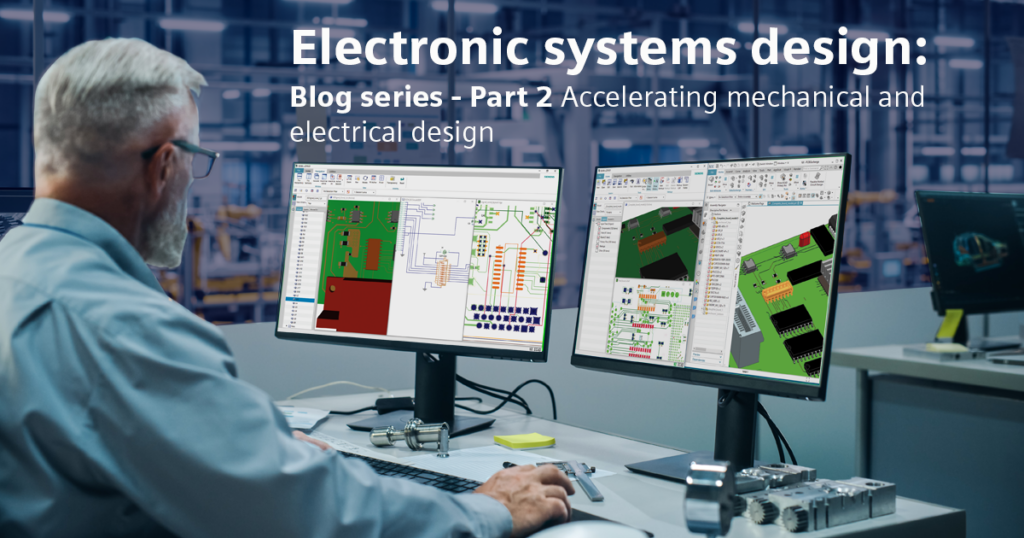

Bridging the gaps in electronic systems design Blog series | Accelerating mechanical and electrical design – Part 2

Seamless collaboration with NX and Xpedition

In our previous blog post, we explored the challenges faced by electronics companies in today’s fast-paced, highly competitive market. Now, let’s dive deeper into one of the most critical aspects of electronic systems design: the collaboration between mechanical and electrical design teams.

The siloed struggles

If you’re an engineer working on electronic systems, you’ve likely experienced the frustration of siloed design processes firsthand. Picture this: you’re designing a complex PCB, and you need to ensure that it fits perfectly within the mechanical enclosure. You import the 3D models into your MCAD tools into your ECAD tool, only to discover that the board doesn’t quite fit. You spend hours, or even days, tweaking the design to make it work, but the more changes you make, the more issues arise.

This scenario is not uncommon. It’s a daily reality for many engineers. The lack of seamless collaboration between MCAD and ECAD tools leads to countless hours of rework, delays, and even costly respins. But what if there was a better way?

The power of integrated ECAD-MCAD collaboration

Imagine a world where mechanical and electrical design teams could work together seamlessly, sharing data in real time and identifying potential issues early in the design process. That’s where the power of integrated ECAD-MCAD collaboration comes into play.

By leveraging tools like NX for MCAD and Xpedition for ECAD, engineers can bridge the gap between mechanical and electrical design, enabling faster, more efficient collaboration. These tools allow teams to:

- Visualize and identify issues in a 3D environment

- Evaluate and propose incremental changes

- Review and validate proposals before implementing them

- Synchronize results between MCAD and ECAD

Let’s look at a real-world example of how integrated ECAD-MCAD collaboration can transform the design process.

An aerospace success story

A global aerospace multinational recently implemented a new approach to electronic systems design using Siemens Xcelerator. By adopting NX for MCAD and Xpedition for ECAD, the company was able to create a digital thread connecting all aspects of the product lifecycle.

Before implementing these tools, global aerospace engineers faced significant challenges in collaborating across disciplines. “It was a lot of manual exporting, importing, and spending time figuring out who made what changes,” said a mechanical engineer at this aerospace company.

However, with the integrated ECAD-MCAD collaboration capabilities of NX and Xpedition, they were able to streamline the design process dramatically. Engineers could now easily visualize and identify issues in a 3D environment, propose and validate changes, and synchronize results between MCAD and ECAD. The results speak for themselves. “We’ve saved significant time,” explained the engineer.

“Instead of wasting hours on new analysis models, we have one NX model. With a few clicks, it is ready for analysis in the corresponding analysis tool.”

Current customer, mechanical engineer at a leading aerospace company

Embrace the future of collaboration

This success story is just one example of how integrated ECAD-MCAD collaboration can revolutionize electronic systems design. By breaking down the silos between mechanical and electronic design teams, companies can accelerate innovation, reduce errors and respins, and ultimately bring better products to market faster.

So, if you’re still struggling with siloed design processes and endless rework, it’s time to ask yourself: is there a better way? The answer is a resounding yes.

Next week, in our next blog post, we’ll explore how simulation can help optimize electronic systems design, reducing the need for physical testing and further accelerating time-to-market. In the meantime, we’d love to hear your thoughts. What challenges do you face in ECAD-MCAD collaboration, and how do you think integrated tools could help? Let us know in the comments below.