Fall Semiconductor Series: How integrated software and automation transform fab sustainability

(Part 3 of 5): The fab is a complex challenge—how do you know where your sustainability journey should begin?

In our Fall Semiconductor Series, we discuss the sustainability challenges faced by semiconductor fabs and why an integrated software and automation solution is the right solution to address these challenges. If you missed our earlier posts, just click on Part 1 or Part 2 of the Series.

In this week’s blog, we focus on the complex challenge presented by the semiconductor fab. Semiconductor fabs are among the most complex manufacturing environments ever built. Chip manufacturing demands atomic-level precision across thousands of interdependent steps—lithography, etching, doping—and each must be executed flawlessly on silicon wafers. It requires specialized equipment, massive capital investment, and mastery across physics, chemistry, and engineering. All of which must be orchestrated with ultimate precision to deliver flawless products profitably and sustainably—at scale.

Considering such a complex model, how do you know where your sustainability journey should begin?

It begins with the digital twin, which is a virtual replica of your entire semiconductor fab—a physics-based model that mirrors how your actual manufacturing processes and systems behave in real time. It is the right first step towards analyzing and understanding the complex operations of the fab for the purpose of optimizing it effectively. The digital twin enables you to accurately predict production performance, test scenarios, and optimize operations without disrupting live production.

Unlimited in its scope for precise modeling, learnings and optimization, the digital twin can be used to model either the actual product or manufacturing process. The digital twin can simulate real-world conditions in a virtual model prior to building a semiconductor product or designing actual manufacturing operations.

It allows you to optimize fab planning virtually without disrupting your operation or without incurring the high cost of actual trial and error on the production floor.

Virtual fab planning enables data-driven decisions

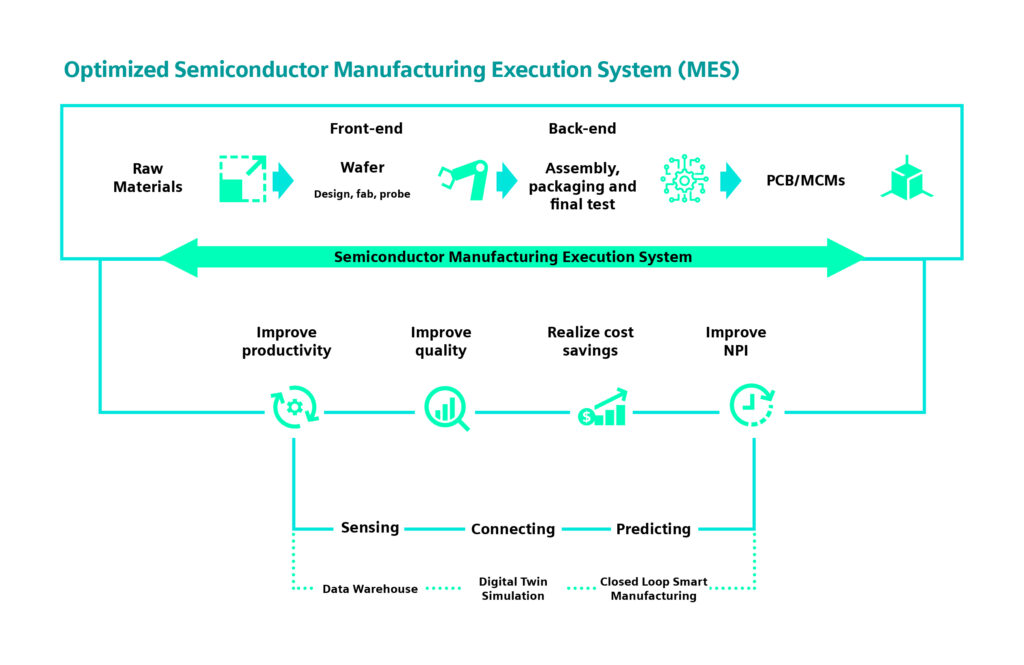

The validated blueprint from the digital twin can be used to orchestrate real-world operations with a seamlessly integrated Manufacturing Execution System (MES), Advanced Process Control (APC) and automated material handling.

With semiconductor manufacturing equipment connected to MES, smart manufacturing can report real-time data collected throughout the fab. This includes data from sensors, actuators and input/output (I/O) modules at the semiconductor equipment level and from subfab facilities and utilities up through every level of product and process recording and tracking. The internet of things (IoT) data and process control data are fed into analytics systems to leverage both historical and predictive analytics to forecast and deliver better future outcomes.

A comprehensive digital twin spanning the entire chip lifecycle can create a powerful feedback loop between design and manufacturing. By simulating production virtually and feeding real manufacturing insights back into design, manufacturers can optimize both chip designs and production processes before physical manufacturing begins.

With the integration of software and automation, digital twin capabilities are amplified across the chip lifecycle. Real-time production data automatically feeds into simulation, while analytics drive rapid process adjustments, creating an intelligent, self-optimizing system that continuously improves both current manufacturing and future chip designs.

Applying the power of data to sustainable outcomes

With end-to-end connectivity across systems, shown in the diagram below, real-time data is collected directly from the semiconductor MES to inform the digital twin and semiconductor specific dashboards.

MES can leverage a digital twin to capture real-time performance data, including Statistical Process Control (SPC) and deviations from manufacturing execution, maintenance, testing and scheduling. Continually updated with MES data in a closed-loop manufacturing system, the digital twin is always ready to provide advanced simulation to discover actionable insights not only for predictive maintenance, but also to identify production and sustainability improvement opportunities, which are significant.

Siemens’ end-to-end sustainability solutions reduce carbon footprints and optimize the use of water, energy, chemicals and gases, ensuring safer handling of hazardous materials. This supports responsible sourcing and better utilization of materials.

Chipmakers and machine builders can design and build future-proof semiconductor fabs by implementing a wide range of digitally integrated automation solutions, reducing energy consumption, enhancing efficiency and productivity, choosing less regulated materials, reducing water consumption and providing people-centric workspaces in operations.

Empowering predictive maintenance

The digital twin also empowers predictive maintenance capabilities, including equipment health monitoring and predictive process performance. Automated response capabilities are enhanced, including predictive part replacement, preventive cleaning cycles, calibration scheduling, resource optimization and environmental adjustments such as gas delivery systems. Additional predictive capabilities include preventing unplanned downtime, optimizing future maintenance schedules, reducing future operational costs, extending equipment lifetimes and more.

With the addition of AI, predictive maintenance is enhanced even further

Additional AI capabilities include pattern recognition and anomaly detection, identifying equipment behavior changes, detecting emerging failure patterns, performing root-cause analysis, making risk assessments and preventive action recommendations.

When combined, the capabilities of the digital twin and AI built on a foundation of smart manufacturing and automation, enable semiconductor manufacturers to plan and execute a sustainable business strategy, from design to production to finished chip.

Sustainability KPIs help manage progress

Designing for sustainability begins with the commitment to reduce the carbon footprint, while establishing key performance indicators (KPIs) to measure sustainability progress and guide the process.

With digital tools such as the Siemens’ SIMATIC Energy Suite, engineering managers can establish MES KPIs in energy monitoring and management, power usage patterns analysis, peak demand management, energy cost allocation, resource utilization metrics, energy per wafer metrics, carbon footprint tracking, load balancing capabilities, cost reduction opportunities and more, while tracking sustainability goal progress.

“By establishing the relevant sustainability key performance indicators early, a business can properly monitor impact and costs in the design process and eventually across the entire value chain.”

— Eryn Devola, Vice President, Sustainability, Siemens Digital Industries Software

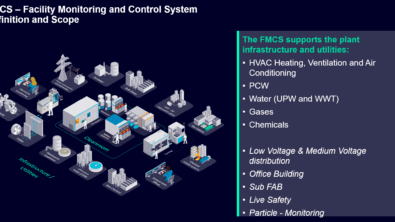

Next week, we will discuss the Siemens Facility Monitoring and Control System (FMCS) and how it equips fabs to streamline workflows, enhance quality control, optimize resource and plant efficiency and boost throughput.

Or if you’d like to discover more about this topic right now, just download our new eBook below, “Using integrated software and automation to transform fab sustainability.”