Evolve from lean to smart manufacturing to optimize production without disrupting lean processes

The time for change is now. While many semiconductor companies have relied on lean manufacturing techniques for decades, smart solutions are now available that can reduce waste and maximize productivity. Today, remaining lean and not evolving to smart manufacturing limits the agility, manufacturing optimization, risk management and competitiveness that are essential to the well-being of every semiconductor manufacturer. We must visualize the future and start working toward it.

What does the smart manufacturing revolution mean for your business? Simply stated, it means embracing smart manufacturing so you can propel progress even further, amplifying profit margins and fostering adaptability required in today’s dynamic climate.

Smart manufacturing equips semiconductor companies to achieve peak performance in fast-changing times

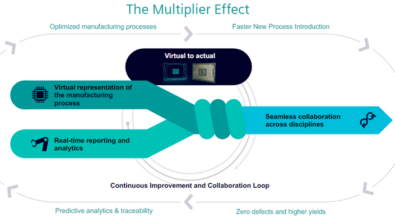

Smart manufacturing adds the digitalization needed to combine simulation, execution control and analytics using real-time production data in a closed loop for continuous optimization in a make-it right-the-first-time, high yield manufacturing process, without disrupting any lean manufacturing gains. This means rapid, data-driven decisions for faster NPIs and faster time to market, with higher yields in a zero-defect manufacturing environment.

Companies need to take three imperative business steps to evolve from lean to smart manufacturing:

- Virtual representation of the manufacturing process

- Leverage the power of digital twins to evolve and optimize semiconductor manufacturing to eliminate defects for higher NPI yields.

- Real-time reporting and analytics

- Activate continuous learning and quality improvement for the insights needed to execute advanced semiconductor fabrication runs with next-gen efficiency.

- Seamless collaboration across disciplines

- With seamless collaboration between the virtual world and the actual world, implement data-driven decisions through a modern MES to deliver the highest levels of initial quality with designs built right the first time.

The evolution from lean to smart manufacturing is key to your company’s success and longevity

With a continuous stream of connected data across all your enterprise, disciplines and domains, you gain the current insights needed to make business, engineering, and manufacturing decisions that work in real time.

When your smart manufacturing is ready for full production, you are equipped and ready to predict production issues early to become prescriptive with real-time performance insights about how and where to make operational adjustments to your MES, adopt AI, and become fully preventive to mitigate risk, achieve first-time right products, increase NPI yields and grow your business. Through this evolution toward smarter production, new technologies and practices are integrated in existing lean programs or techniques. It all begins with a progressive evolution from lean manufacturing to smart manufacturing. Siemens can help to execute your digital transformation, boosting your competitiveness and increasing speed to market supported by secure, robust resources on the cloud.

Download the eBook to learn more about this new revolution from lean to smart manufacturing

Projections indicate substantial advancements enabled by smart manufacturing:

- Up to 20% rise in throughput

- Reduction of expenses by approximately 15%

- Potential income enhancement of roughly 10%

- Mitigation against threats posed by cybersecurity breaches and regulation violations

Start to amplify profit margins and foster the adaptability required in today’s dynamic climate.

To discover more of what’s possible with our end-to-end digital solution, visit https://xcelerator.siemens.com/global/en/industries/use-cases/smart-manufacturing.html#Smartmanufacturingsolutionsbyindustry