Modern day PCB design in the age of AWS Cloud (Part 3 of 3: Ensuring reliability and performance)

In Part 1 of our blog series, we learned about the partnership between Siemens EDA and AWS and how it will transform modern day PCB design. In Part 2, we further learned how this partnership sets a benchmark for what is achievable in terms of security and compliance. This final blog in our series examines how AWS’s global infrastructure and innovative services elevate the operational capabilities of the Siemens EDA PCB design & analysis tools, ensuring they perform optimally under any conditions.

Ensuring reliability

For Siemens EDA, the integration of AWS’s services has been pivotal in achieving unparalleled reliability in our cloud-connected PCB design tools. The infrastructure provided by AWS plays a critical role in ensuring our tools are available and perform optimally, regardless of the user’s location or the complexity of the tasks being performed.

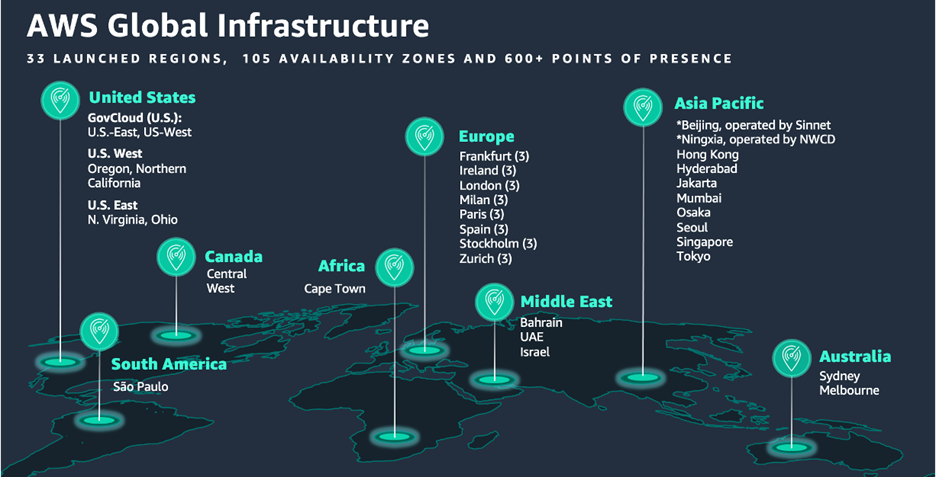

- Global infrastructure: AWS’s extensive global network of regions and availability zones is designed to minimize latency and maximize redundancy. This setup ensures that if one zone encounters an issue, others can compensate, thereby maintaining service continuity.

- Fault tolerance and disaster recovery: By deploying across multiple AWS availability zones, Siemens EDA ensures that our applications are not only fault-tolerant but also capable of rapid recovery in the event of a disaster. This geographical distribution safeguards against a range of potential failures, from natural disasters to system outages.

Monitoring and site reliability

Maintaining operational excellence in cloud-based applications requires sophisticated monitoring and rapid response systems. At Siemens EDA, we leverage a variety of AWS tools to monitor their applications and ensure they operate reliably.

- AWS CloudWatch and DataDog integration: These tools allow us to monitor AWS systems comprehensively, from infrastructure metrics to application-level performance. CloudWatch helps detect anomalies and set alarms for proactive issue resolution.

- Site Reliability Engineering (SRE): Our Siemens EDA solutions also benefit from an experienced team of SRE engineers as part of our corporate-wide Xcelerator Cloud platform. These professionals are instrumental in responding to and mitigating issues as they arise, ensuring that downtime is minimized and service levels are maintained.

Performance optimization

Performance is a critical factor in PCB design, where simulations and real-time data analysis demand high computational power. AWS provides Siemens EDA with the resources needed to ensure that our cloud applications not only meet but exceed performance expectations.

- Compute and storage services: AWS offers a range of compute options, including EC2 instances with various configurations to suit different needs. For storage, services like Amazon S3 and FSx provide scalable, high-performance options that support intensive workloads typical in PCB design, such as simulation and DFM analysis.

- Auto-scaling and load management: At Siemens EDA, we use AWS Fargate, which allow us to scale our container resources automatically based on demand. This elasticity allows us to manage compute loads efficiently, ensuring that performance remains consistent, even under varying loads and conditions.

Modern Day PCB Design has been transformed by the cloud. The partnership between Siemens EDA and AWS redefines what’s possible in PCB design, setting new standards for security, reliability, and performance in the industry. By leveraging AWS’s robust global infrastructure and cutting-edge cloud services, we not only address the complex needs of today’s PCB design teams, but also are well positioned to rapidly support future innovations. As cloud technologies evolve, Siemens EDA continues to lead in delivering high-performance, reliable, and secure PCB design tools and workflows that empower engineers worldwide, enhancing both productivity and creativity.