Behind the TLA Winners: Curtiss-Wright

The 1st place winner in the Military & Aerospace category is Curtiss-Wright from Ottawa, Canada

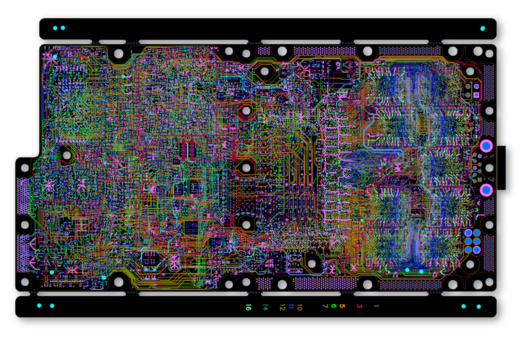

This design is ruggedized single board computer with a 4 core 8 thread processor designed within a small board envelop of on under 6×3 inches.

This XMC-121 is a ruggedized mezzanine computer SBC mounted onto other line cards. This small form factor design of under 6 x 3 inches houses a 4 core 8 thread processor which presented many thermal and structural challenges.

- Ashleye Soanes, Pascal Sauvé, Luc Bouchard and Stephen Reich

Design flow used:

- Xpedition® Enterprise (extensive use of HyperLynx reduced part count by several hundred components)

Design challenges:

- Constraints: With 70% high-speed nets this highly constrained design required SI, PI, thermal and digital analysis as well as validation for DFM, vibration, fabrication, assembly, test and reliability.

- Technology: The Intel Xeon platform on a mezzanine form-factor presented particularly mechanical/thermal challenges. This XMC-121 is cooled entirely by conduction. To provide additional cooling the PCB is cutout at that edge to provide a direct interface from the heatsink right to the carrier board metalwork. Also, the DDR4 SDRAM interface validation drove many design decisions such as those regarding stackup (impedances and geometry), layer count and layer assignment, floor and route planning, the termination scheme and so on.

- Power Supply: 134A of aggregate peak current output from 14 leading-edge onboard DC-DC converters.

- Electro-mechanical: Mechanical constraints limited layout count and thickness, restricting the PDN design.

- Stack-up: The stackup definition was primarily driven by the opposing constraints of having sufficient routing layers to accommodate 2 channels of 64-bit (+ 8-bit ECC) DDR4 SDRAM on one hand, and constraining PCB thickness to support placement of selected devices on secondary side.

Judge’s comments:

- “One of the highest component densities of all entries”

- “Nice Double sided HDI place and route”

- “2nd highest routing density. Good placement”

- “This is one of the best designs in the competition”

About the Technology Leadership Awards

Started in 1988, this program is the longest running competition of its kind in the EDA industry. In fact it is the industry’s only award where design teams using Mentor’s solutions receive recognition by an independent panel of experts for overcoming the most extreme challenges facing PCB design teams today. Just look at the winning designs from previous years to get a sense of the types of technologies and industry segments that are represented in this program. A listing of all of this years winners along with a Technology Leadership Awards webinar are both available for more in-depth information.

Please check back for the next blog in this TLA winner series for a closer look at the runner-up in the Military and Aerospace category.