ECAD MCAD off-highway design process helps eliminate electromechanical issues

Design teams can eliminate costly electromechanical issues during development by using an efficient ECAD MCAD off-highway co-design process. Integrated electrical and mechanical applications can help designers understand their counterpart’s domain, identifying and resolving incompatibilities early to reduce costly design iterations.

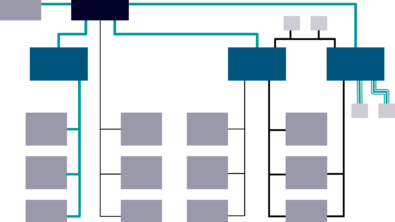

As electrical systems grow in size and sophistication, the challenge of designing off-highway vehicles is mounting. A network of electronic control units (ECUs) and sensors monitor and control the critical systems in these vehicles. ECUs monitor the temperature, pressure, and position of various components and can control the actuation of hydraulics, engine valves, and more. The increasing electrification of off-highway vehicles is similarly evident in the cabin. Contemporary agricultural tractors, for example, feature electronic and digital controls as well as cabin amenities like heated seats and climate control systems (figure 1).

As the electrical and electronic content of off-highway vehicles continues to grow, the interactions between the electrical and mechanical systems will grow in step. Waiting until prototyping to validate ECAD and MCAD compatibility is not an option for today’s off-highway manufacturers. The fit and function of the wiring harness and all associated electrical components, with the vehicle frame and all associated mechanical hardware, must be ensured during the design phase.

The optimal strategy is to use a system that allows for ECAD and MCAD design data to be exchanged consistently throughout the design process. With consistent communication, ECAD and MCAD teams resolve issues early, preventing costly rework late in the design cycle. They can also optimize the vehicle design to meet evolving constraints while maintaining quality, performance, and reliability standards. Finally, ECAD and MCAD designers are able to collaborate from within their own design environments without learning new tools. Consistent and iterative communication between ECAD and MCAD teams reduces time-to-market, enables the creation of more accurate designs, and increases productivity.

ECAD-MCAD co-design is easier said than done. Traditionally, the electrical and mechanical domains are separated; engineers work with completely different tool sets and have completely different vocabularies. Mechanical and electrical CAD systems have different ways of presenting the structure of the same object. Many times, they even reside in different physical locations.

Modern ECAD and MCAD tools support API level integrations, where the two domains are connected directly to immediately update designs with changes or new information. A key feature of such integration is replacing cumbersome file-based exchanges that depend on manual exportation of a massive file of changes into a file system for the other engineers to retrieve and then import.

With this integration, the electrical system and wiring harness can be designed with explicit contextual knowledge from the mechanical design. On the mechanical side, space reservations can be made to ensure that wiring bundles will conform to minimum bend radius and diameter constraints for routing through conduits in the mechanical structures.

ECAD-MCAD co-design is a powerful strategy to increase productivity and ensure robust off-highway vehicle designs. With modern engineering software tools, designers are able to synchronize their data more efficiently and collaborate more effectively on critical design items between domains, thereby ensuring that the design intent is properly implemented.

During design, integrated electrical and mechanical applications help designers understand their counterpart’s domain. Incompatibilities are identified and resolved early, reducing costly design iterations. There is added benefit in tightly coupled applications that contain design rule checks and can capture your design best practices. Imposing those best practices will ensure the electromechanical systems in off-highway vehicles are able to withstand the difficult working conditions in which they must perform. ECAD-MCAD co-design, with rich change management support, is empowering for design engineering teams as they optimize off-highway vehicle designs for reliability and performance.

To learn more, download our whitepaper Automated ECAD-MCAD Co-Design for Enhanced Off-Highway Vehicle Design.