The origins and impact of Siemens Capital integrations

In the data-intensive product development world, design accuracy, efficiency and traceability are more critical than ever. For electrical/electronic (E/E) engineering teams, Siemens Capital integrations have become a cornerstone of this goal.

Capital integrations connect electrical design with the broader product development ecosystem, bridging tools for mechanical design, systems engineering, simulation and lifecycle management to enable seamless, traceable and efficient development. We’ve come a long way since the days of manual data re-entry and disparate systems, evolving toward a connected, automated workflow that improves accuracy, accelerates timelines, and empowers teams to make better design decisions with confidence.

But as the saying goes, Rome wasn’t built in a day. Our integrations evolved in response to customer demand to end the frustration of disconnected tools and manual, error-prone processes.

This blog explores the origins, evolution and benefits of Capital integrations, and how they’re transforming design workflows and product quality across industries.

Before Capital Integrations: Human “Integrations”

Before digital integrations were possible, electrical and mechanical teams relied on manual processes and physical interactions to align their designs. This phase could be referred to as “human integrations.”

“Designers often had to walk down the hall to consult with MCAD engineers or even examine prototype vehicles to determine placement of components like fuel tanks and connectors,” explained Siemens Product Manager Chad Holly in a recent presentation at Realize Live 2025. “Sometimes, they used plywood mock-ups just to simulate the packaging and wiring layout.”

While these efforts fostered collaboration, they were error-prone and inefficient – a missed measurement or miscommunication could result in costly rework.

“Once, after forgetting to validate a harness segment, I ended up with an extra 99-inch wire bundle in a prototype military vehicle,” Holly said. “It was a tough lesson that highlighted the need for better synchronization and automation.”

The challenges of the past make a compelling case for Capital integrations, which aim to accelerate workflows, improve traceability and build confidence in the data being used across the development lifecycle.

The Journey to Flexible Integrations

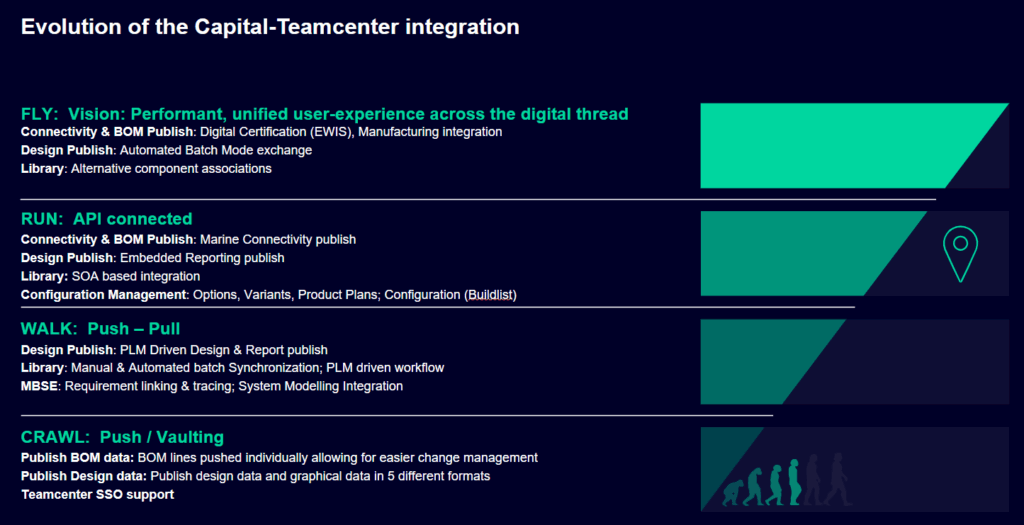

The journey of Capital integrations can be described as a 4-phased evolution:

- Crawl: In the early days, integration between Capital and Teamcenter was file-based and unidirectional. Engineers could export design data, but there was no dynamic synchronization.

- Walk: The integration matured into a bidirectional exchange, allowing for data to be pushed and pulled between systems.

- Run: With the advent of API-connected integrations, data became much more dynamic. Synchronization could happen in real time, with improved automation and fewer errors.

- Fly: Siemens is now moving toward a vision of high-performance, seamless user experiences, with electromechanical co-design and orchestration through Teamcenter enabling collaborative workflows across domains.

With integrations in place, teams no longer have to manually transfer design data between systems; electrical design data flows seamlessly into all systems, minimizing the risk of miscommunication or conflicting data. What’s more, designers can collaborate in real time, and maintain an audit trail of changes along with their origin and impact.

How Capital Connects with the Broader Product Development Stack

Siemens Capital integrations act as bridges that link electrical design tools to a broader product ecosystem. This ecosystem includes:

- Teamcenter for Product Lifecycle Management (PLM): Teamcenter is Siemens’ comprehensive PLM system that manages the lifecycle of a product from initial concept through design, manufacturing and service. In the context of Capital integrations, Teamcenter serves as the central hub for managing design data, electrical Bills of Materials (BOMs), workflows, change management and product configurations. This enables traceability, revision control and a single source of truth across engineering domains.

- NX for Mechanical Computer-Aided Design (MCAD): NX is Siemens’ flagship mechanical CAD tool used for designing, modeling and simulating 3D mechanical components and systems. Integrated with Capital, NX allows mechanical and electrical teams to work together through electromechanical co-design. For example, electrical harness designs created in Capital can be visualized and routed directly within NX, while spatial and packaging constraints from NX inform the electrical topology. This tight integration supports early design validation and improves product quality by reducing physical prototypes and rework.

- IBM Rhapsody for Model-Based Systems Engineering (MBSE): IBM Rhapsody is a widely used MBSE tool for developing complex, embedded systems using Unified Modeling Language (UML), Systems Modeling Language (SysML) and other visual modeling approaches. Integrating Rhapsody with Capital enables systems engineers to trace functional and behavioral requirements to the physical implementation in electrical designs. This supports early requirements validation, change impact analysis, and consistent system-level documentation across the engineering lifecycle.

- Simulation Tools: Capital integrates with various simulation platforms to support virtual testing on electrical systems, such as verifying harness integrity, assessing electromagnetic interference (EMI) or testing power distribution. These simulations reduce the need for physical testing and help teams catch potential issues early in the design cycle.

- Third-Party or In-House Solutions: Siemens Capital’s integration framework is intentionally open and extensible, allowing it to connect with third-party tools (e.g., Dassault Systèmes CATIA for MCAD, PTC Windchill for PLM, or MATLAB/Simulink for system modeling) as well as proprietary, in-house systems developed for specific workflows.

These integrations are purpose-built to function in heterogeneous environments, freeing teams from being locked into a single stack of Siemens tools. Importantly, the integration platform is open and extensible by design, offering support for APIs, custom extensions and dynamic data exchange between systems.

A Stronger Foundation for Innovation

By enabling deep, bidirectional integrations across disciplines, Siemens Capital helps organizations unlock the full potential of their engineering teams. No more siloed workflows, no more costly misalignment – just data flowing seamlessly across your ecosystem, empowering teams to move faster and build with confidence.

Whether your organization is designing electric vehicles, aircraft or complex industrial systems, integrated workflows are essential. With Siemens Capital and Capital X software as a service solutions, you gain the traceability, flexibility and seamless user experience you need to fuel innovation in a world where speed and quality matter more than ever.

Watch the full recording of our presentation at Realize Live, Evolution of Capital integrations into the Xcelerator ecosystem.