Can machine learning and neural networks accurately predict post-deposition profiles for CMP modeling?

By Ruben Ghulghazaryan and Jeff Wilson – Mentor, A Siemens Business

We experimented with machine learning and neural networks for CMP deposition profile modeling, and the results were promising. Learn more about this exciting use of new technology.

Chemical-mechanical polishing (CMP) is a key activity in today’s integrated circuit (IC) manufacturing process. With designs so tightly packed, and scaled down to the most advanced process technology nodes, post-CMP planarity variations can have a significant impact on manufacturing success. Most IC manufacturers use CMP modeling to detect potential hotspots in front-end-of-line (FEOL) and back-end-of-line (BEOL) layers as part of their design for manufacturing (DFM) flow. The main concept behind CMP modeling is to extract geometrical properties of the pattern on the layout, generate a pre-CMP surface profile after etch and numerous deposition steps, and predict the post-CMP surface profile for different patterns on the layout.

Isolation of transistors from one another with high quality dielectrics and other applications lead to invention of new advanced deposition technologies, such as flowable chemical vapor deposition (FCVD) and enhanced high-aspect-ratio process (eHARP), that allow void-free deposition in features with an aspect ratio of 12:1 and higher. Generation of a high quality pre-CMP surface profile is crucial for CMP modeling, due to the complicated nature and long range effects of the CMP process. Even with advanced deposition processes, the pre-CMP profile on patterned wafer is non-uniform. It may contain large variations that can affect on-surface planarity after CMP.

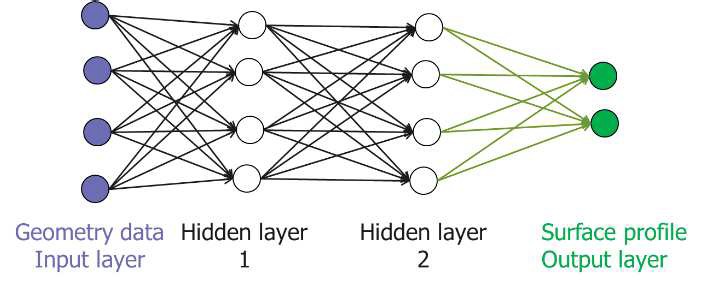

Building physics-based or compact models for FCVD and eHARP is challenging, since these processes include several deposition and annealing steps to fill up trenches. However, machine learning (ML) in conjunction with neural networks (NNs) has demonstrated the ability to “learn” how to analyze and predict imprecise data. We explored the use of ML algorithms for sensitivity analysis of measurement data, which showed that the post-deposition surface profile for these processes depends mainly on the underlying pattern geometry, while long-range effects are secondary. With this information, we then applied NN regression calculation to the modeling of the pre-CMP surface profile, using as input the geometric characteristics of the underlying pattern.

In our experiments, a simple feed-forward NN with two hidden layers and a small number of neurons on hidden layers was successfully used for surface profile modeling of high-density plasma CVD (HDP-CVD), spin-on dielectric (SOD), FCVD, and eHARP deposition processes, with more than 95% correlation and a small error per site. Based on the results of our research, the application of ML with NNs to deposition profile modeling looks promising. If you’d like to see the details and learn more about our process, check out our white paper, Using neural networks for oxide deposition surface profile modeling for CMP.