Want improved design optimization? Try integrating pattern matching with DFM properties

By Sherif Hany, Mentor – A Siemens Business

Integrating pattern matching with DFM operations ensures designs are quickly and accurately optimized for reliability, performance, and manufacturing prior to tapeout

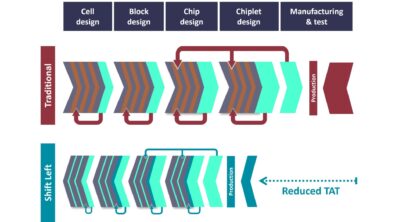

If I say “pattern matching,” an IC designer would probably respond with “litho hotspot.” True, finding lithographic hotspots in layouts is one of the earliest and still more common uses of pattern matching, but pattern matching is increasingly being used in a wide range of early design phase checks, DRC flows, layout retargeting and fixing and DFM checks.

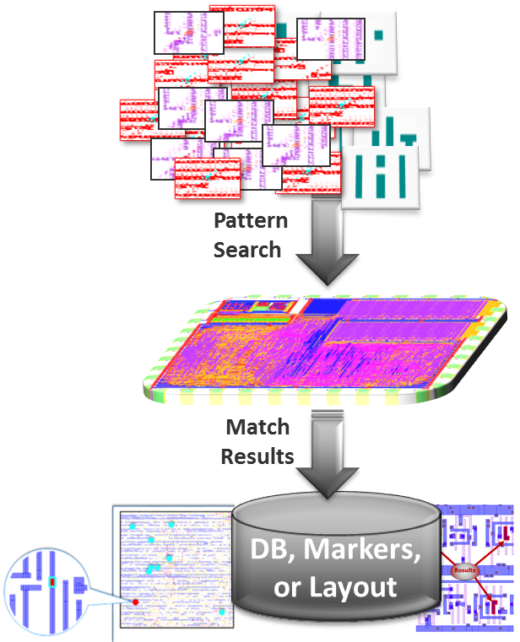

In these flows at advanced nodes, designers are combining pattern matching with DFM properties to better achieve a variety of design optimization and enhancement goals. DFM properties are one form of design metadata associated with layout objects (such as polygons and edges) that are used for calculating DFM scores and filtering data. Pattern matching has two stages: capture and match. In the capture stage, where designers select areas of interest in a design, input can be filtered by selecting locations and polygons that have certain DFM properties. In the matching stage, the derived layers (pre-filtered) are passed as input, and the matched locations undergo post-processing by inspecting the output.

In these flows at advanced nodes, designers are combining pattern matching with DFM properties to better achieve a variety of design optimization and enhancement goals. DFM properties are one form of design metadata associated with layout objects (such as polygons and edges) that are used for calculating DFM scores and filtering data. Pattern matching has two stages: capture and match. In the capture stage, where designers select areas of interest in a design, input can be filtered by selecting locations and polygons that have certain DFM properties. In the matching stage, the derived layers (pre-filtered) are passed as input, and the matched locations undergo post-processing by inspecting the output.

So, what are some of the typical uses?

- Orientation checking—analyze and validate legal metal/device orientation; check for orientation uniformity and consistency in ESD protection structures

- Orientation-aware fill—allow consistent handling of similar patterns by doing classification and handling for unique patterns before back-annotating the processing results to all the original patterns. This flow is essential for meeting design requirements on both electrical and process sides.

- User-defined pattern properties—apply equation-based DRC for actions like partial pattern match identification, then use the mismatch percentage to determine if and how the selected geometry should be adjusted to fully match the target pattern.

- Vector properties—accumulate all values of a DFM property, and display all versions of that DFM property that share the same location. This vector information can then be used to perform activities such as pattern clustering analysis and symmetry analysis.

- Context-aware checks – combine the PM with topological pattern matching to access a new dimension of checking device and net patterns.

If you’d like to know more about the wide range of uses this combination enables in design enhancement and optimization, download our white paper, Integrating Pattern Matching with DFM Properties to Enhance and Optimize Layouts. Not only will you get a more detailed look at these processes, but you’ll understand exactly how integrating pattern matching with your DFM operations can help you more quickly and precisely optimize your designs for reliability, performance, and manufacturing.