Accelerating innovation through continuous simulation-driven decision-making

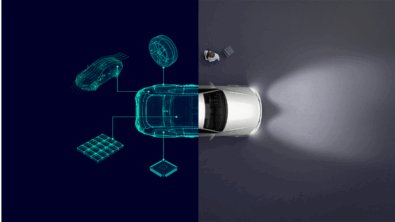

The shift to software-defined, connected and increasingly autonomous vehicles has upended the traditional automotive development model. What once was a sequential, hardware-first process has become a multidimensional challenge — one where mechanical, electrical and software systems evolve in parallel, each influencing the other in real time.

This complexity presents both a risk and an opportunity. For OEMs, staying competitive means more than optimizing individual components — it requires orchestrating performance, safety and innovation across the full vehicle architecture. And one of the most effective ways to do that? Simulation. Not just early in the process, but continuously, at every stage of development.

With continuous simulation-driven decision-making — a core principle of Siemens’ approach to Simulation and Test — engineering teams gain the insight and agility to design smarter, validate earlier and launch faster.

Bringing performance and compliance into focus, sooner

Historically, simulation was used to validate late-stage decisions — often after significant investment had already been made in physical prototypes. But as vehicle platforms grow more complex, that approach is no longer sufficient.

Simulation must move upstream. By incorporating realistic system models into early-stage design, engineering teams can analyze how software, electrical and mechanical systems interact, and resolve issues before they cascade into costly delays.

For example, using Siemens model-based systems engineering (MBSE) solutions, teams can model multi-domain systems and evaluate tradeoffs like power consumption versus performance, or thermal load versus range — all before hardware is built.

This frontloading of simulation enables teams to:

- Catch integration issues before they derail downstream phases

- Quantify and optimize architectural tradeoffs (e.g., weight vs. cost vs. durability)

- Validate functional safety and cybersecurity requirements early in the design process

It’s a foundational step toward faster iteration, fewer physical test cycles and better product outcomes.

Connecting development silos through a shared simulation backbone

Modern vehicles aren’t developed in silos, so simulation environments shouldn’t be either. Siemens supports the continuous coordination of cross-domain teams through its Systems Engineering and Application Lifecycle Management (ALM) solutions.

Using shared modeling frameworks, engineers across domains can model behavior, validate interactions and simulate real-world performance in parallel. This leads to more cohesive architectures, tighter alignment between hardware and software and fewer disconnects during handoffs.

As design decisions are made, they’re continuously evaluated in context — not just for form and function, but for safety, performance and compliance.

This closed-loop feedback also supports iterative refinement. Each simulation insight informs not only the current phase but the next, creating a virtuous cycle of engineering intelligence.

Accelerating ramp-up and reducing risk with virtual commissioning

Continuous simulation extends beyond design. In the integration and verification stages, virtual commissioning techniques like Model-in-the-Loop (MiL), Software-in-the-Loop (SiL) and Hardware-in-the-Loop (HiL) allow teams to test real-time behavior, safety features and control logic — long before physical systems are available.

By leveraging MBSE for system simulation, teams can reduce reliance on road tests, cut iteration cycles and validate with confidence.

Simulation also strengthens cybersecurity strategies. By modeling potential attack vectors and testing system responses, teams can uncover vulnerabilities and embed defenses at the architectural level, ensuring resilience from day one.

Future-ready vehicle programs start with simulation

The automotive landscape is shifting fast. New propulsion systems, advanced driver assistance features and evolving global regulations are raising the bar for innovation and shortening the timeline to meet it.

Continuous simulation-driven decision-making equips engineering organizations to meet that challenge head-on. With the ability to explore, test and refine complex systems in a virtual environment, teams can innovate boldly while managing risk.

It’s a strategy that doesn’t just improve engineering — it transforms it.

Learn how Siemens’ MBSE connects design, simulation, test and data management to help automakers deliver safer, smarter and more sustainable vehicles at speed, and find out how you can put yourself in the driver’s seat.