ETH Zurich uses NX, Teamcenter, and Simcenter to take student design to the next level

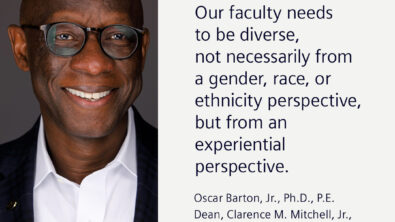

Siemens products help Swiss university to prepare students for high-level product development

Zurich, Switzerland

By: Hannah Straub

Students currently studying engineering and computing are being taught early on in their education about the fundamental knowledge and skills required to perform effectively once they enter the industry. The Swiss Federal Institute of Technology (Eidgenossische Technische Hochschule: ETH) in Zurich Switzerland prides themselves on their dedication to their students, especially amid groundbreaking technological advancements.

“A good university doesn’t just impart knowledge, it also teaches people to think,” says Lino Guzzella, president ETH Zurich. “This is why we teach fundamental knowledge and skills at the highest international level: to ensure students are equipped to deal with current and future challenges.”

Established in 1855, the Swiss Federal Institute of Technology (Eidgenössische Technische Hochschule: ETH Zurich) is a national center for education with international appeal. Over 500 professors teach 20,600 students including 4,100 doctoral students from over 120 countries. With 21 Nobel Prize winners among its alumni, ETH Zurich ranks among the world’s leading science and technology universities.

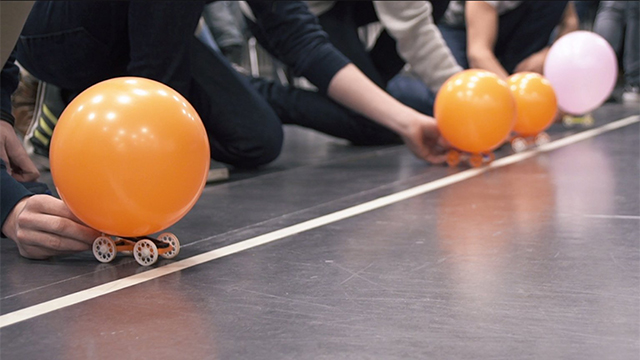

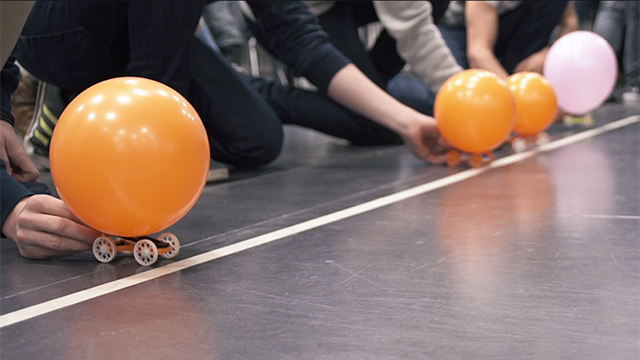

“We educate students for excellence and leadership in science and industry,” says Dr. Kristina Shea, professor of engineering design and computing at ETH Zurich. “Our challenge is the wide variety of backgrounds the 500 first-year students of mechanical and process engineering come with.” During the first semester, students learn how to manually sketch before starting on CAD in which they design, build, and race balloon-powered model cars.

“We try to educate students to employ systematic thinking, so they create good designs,” says Shea. “Teaching them to combine computational design and digital fabrication, we attempt to prepare them as best we can for the challenges they will be facing in their future careers.” After creating the cars, the students launch them to see which design is best and have a pretty good time judging each other’s work.

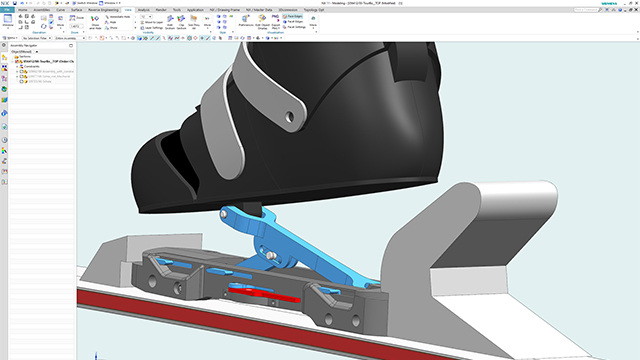

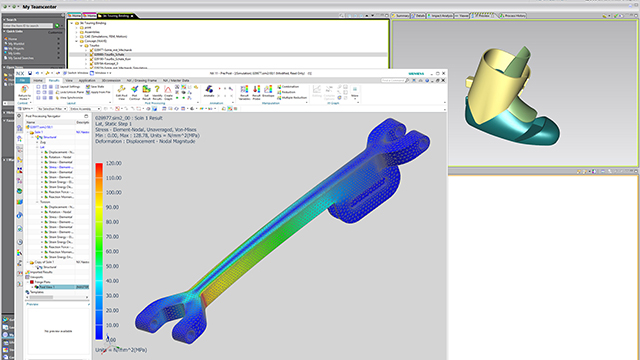

During the third and final year of their courses, they work on focus projects. A team of five mechanical engineering students and one industrial design student developed a revolutionary mechanism to link boots and alpine ski bindings. Using the principle of the alpine bindings, existing bindings allow lifting the heel for uphill walking. The students followed an entirely different approach while working on this project and integrated the touring function with the boot, and named it TourBo, derived from touring boot. This team used NX to follow all the design steps, from defining requirements to detail design. Only after they had tested and optimized their design for functionality using NX to perform structural analysis and kinematic simulations, they produced all documentation to build a prototype.

Some challenges that students are preparing to tackle with these acquired skills include:

- Career challenges

- Product development and production

- Combining methods such as sketching, modeling and simulation

- Using digital twins for virtual testing

Students were taught how to combine computational design and digital fabrication and to use NX for all design and engineering tasks as well as Teamcenter for PDM and workflow-driven collaboration.

As a result, students developed a patented mechanism design to link boots and alpine ski bindings, all the while enabling themselves to use Siemens software products to prepare for careers in top-level product development. The project empowered students to design and build electrical race cars from scratch and is equipping them with broad knowledge and solution-oriented thinking.

To read the full case study, click here.