The secret’s in the SaaS: how automakers can stay competitive in a digital future

What has volatility looked like recently?

For one, it’s the vulnerability of the supply chain showing itself with the difficulty of importing chips needed to develop vehicles with advanced features. Also, if you’ve tried to hire local talent, you may have found it challenging as unemployment remains at records lows as nearly 10 million jobs remain open.

Within the automotive industry, the already fiercely competitive landscape continues to grow along with customer demands for smarter, more connected products.

This volatility may sound very doom-and-gloom, but the truth is automakers and suppliers can meet these challenges by finding ways to remain agile and flexible in ever-changing conditions. What they’ll need is to use the right digital tools that allow their teams to collaborate more efficiently, scale up quickly and identify issues sooner in the design process.

That’s where the benefits of software as a service (SaaS) come in.

Siemens has invested in software as a service technology because it’s a solution designed to bring accessibility, agility and flexibility to companies of all sizes, from startups to legacy OEMs.

Using SaaS in today’s competitive landscape

Automotive industry companies face significant challenges as they increase their efforts to develop advanced mobility solutions. Automakers and suppliers will need to adapt to support the technological advances in batteries, electronics, and other electrical components in new vehicles as well as meet evolving consumer demands and manage unpredictable supply chain disruptions. Let’s not forget this has to be accomplished at a quicker pace as development timelines shrink.

Automakers must become more agile and flexible so that they can shift directions as the market and manufacturing demands change.

How does SaaS help companies meet these challenges? It opens up the ecosystem to allow better collaboration amongst internal teams and suppliers, both of which maybe be siloed internally or work remotely.

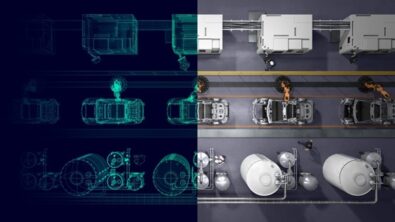

Think about how much time is dedicated to waiting. If a siloed team is working on information, other teams are isolated for a period and then later adapt to the change. SaaS can ensure engineers from multiple domains, suppliers and all stakeholders are working off a single source of truth. Bridging this all together is the comprehensive digital twin combining the real and digital world and allowing automakers to test the performance of their final product early, identifying issues and resolving them while they’re still cost effective.

These collaboration opportunities connect your company to the digital future.

Where IP and security are critical, the owner of the data can decide who in the organization has permission to make certain changes. This way suppliers and other external stakeholders can design and engineer the parts necessary to make the product while testing and validating its overall performance.

As teams work to fulfill local requirements, they’ll be able to track changes and updates ensuring every team member can sign in from anywhere, on any device with internet connection and work from the same data. This is far more efficient than saving data locally, emailing or uploading it and waiting for the next iteration.

The automotive industry and the road to digitalization

Digital transformation enables automotive companies to approach transportation and mobility with a competitive, innovative mindset.

At the heart of digital transformation is the comprehensive digital twin which captures every aspect of vehicle design and production. A digital twin connects engineering teams from across the electrical, electronic, software and mechanical domains so that they can manage the complexity of designing the vehicles of the future and turn it into their competitive advantage.

How you go about embracing digitalization is wholly based on your company and needs. At Siemens, we understand that there is no one-size-fits-all strategy for digital transformation. With Siemens Xcelerator as a Service, companies can scale up and down based on their needs, have the necessary, best-in-class software available that they can execute quickly and broaden their talent pool and supply chains with its open ecosystem of partners and collaborators.

This means you’re receiving a maximum value from your investment in the most advanced technology in a matter of days without the high costs, lengthy deployments or long-term contracts. With Siemens Xcelerator as a Service, the required infrastructure, maintenance, upgrades and even additional IT resources are part of the subscription-based offering. When you need to bring on more users, it’s a simply a matter of onboarding them quickly

Everyone from legacy automotive OEMs to startup suppliers can all benefit from working cohesively in a SaaS environment.

Learn more about Siemens Xcelerator as a Service and how you can innovate without limits by giving your designers and engineers access to on-demand functionality.

More resources:

Automotive Industry Outlook 2023: The value of a startup mindset by Nand Kochhar, vice president of Automotive and Transportation Industry Strategy for Siemens Digital Industries Software.

SaaS is the future of innovation

How digitalization in the automotive industry benefits manufacturers