Failures Due to Counterfeit Materials Don’t Have to Be a “Cost of Doing Business”

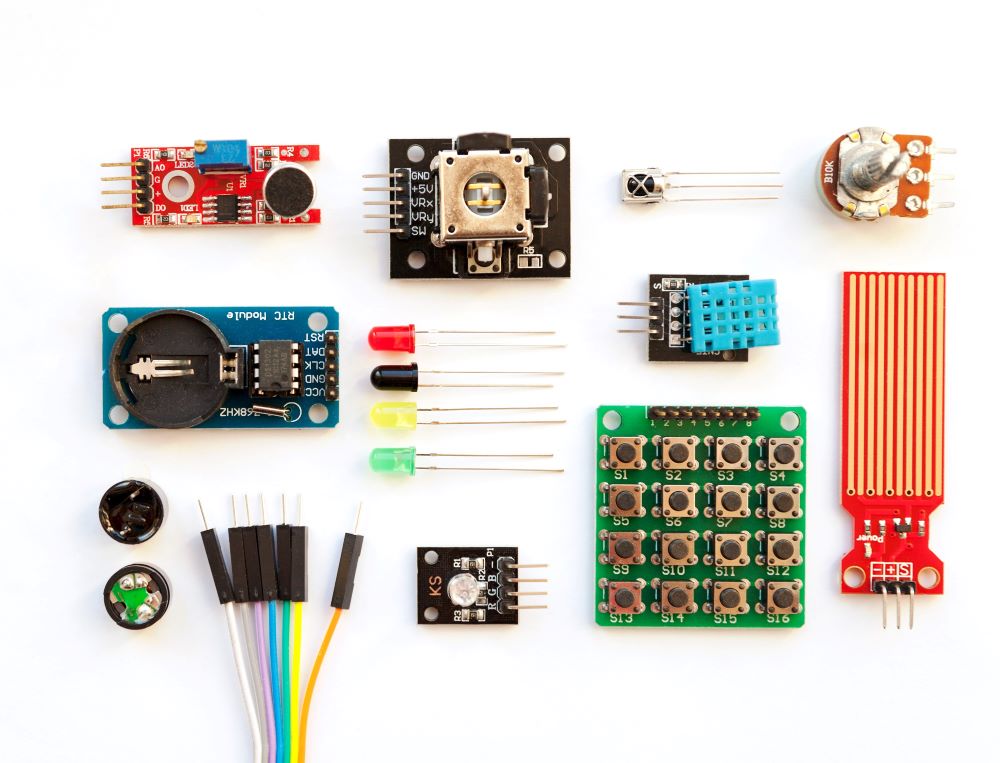

Counterfeit components and materials are widespread across all manufacturing sectors, including electronics manufacturing. I’ve seen several reports estimating that around 10% of components used by electronics manufacturers are counterfeit – and that includes materials from the official vendor.

What drives the creation of counterfeit components? First and most obvious is the profit motive. But another common reason is to insert malicious code into products and systems as part of competitive or even political sabotage.

Counterfeit materials may trigger statistical failures at any point in the product lifecycle. Statistical failures are usually written off as a “cost of doing business”. In some cases, the failures may lead to costs and penalties associated with return merchandise authorization (RMA).

Counterfeit material traceability changes the game

It used to be impossible to efficiently verify every individual component used in electronics manufacturing. Simply checking the label of each reel rarely revealed evidence of counterfeiting or defects.

That has now changed, thanks to the introduction of solutions that enable an unprecedented new level of material traceability, empowering manufacturers to ensure that only new, genuine, and unadulterated components are allowed into a product.

For example, the new Valor-Cybord solution scans each component inline during assembly. Using AI-based image processing, which leverages data that is anyway collected by the pick and place machines, the counterfeit materials traceability solution can immediately identify counterfeit components. The whole process occurs inline. The system also provides a detailed report that can be used to make various decisions regarding quality, conformance, and sourcing.

The integration of Cybord into Valor solutions is part of Valor’s “micro-solutions” initiative, which aims to provide specialized solutions for various challenges specific to electronics manufacturing, using advanced technologies such as AI and ML.