A new level of component traceability: Fighting malicious code and counterfeit components

Co-authored by: Dr. Eyal Weiss, Zeev Efrat (Cybord), Tovi Yadin (Valor, Siemens)

The electronic manufacturing shop floor collects traceability data to a certain degree: process traceability, material traceability. But how can you be certain that the components which you placed on a certain board are indeed original? How can you guarantee that you do not suffer from the well-known phenomena called “Counterfeit components”?

Counterfeit components are estimated at 5-10% of components, causing huge damages to the electronics industry. In addition, many cyber-attacks are incepted by infiltration through the supply chain. Components are rarely tested, and counterfeit or tampered components infiltration is seldom avoided by current mitigation methods. They cause failures later in the product life cycle and lead to poor quality, lawsuits and costly recalls.

According to EPSNews, the effect of Covid-19 on the production of components will inflict an even more severe shortage than the 2017-2018 crisis. When the market bounces back there will be a shortage of electronic components, creating an opening for a flow of counterfeits.

Many manufacturers are not aware of the extent of counterfeit components they use. They may encounter statistical failures later-on in the product life cycle that will be signed-off as the “cost of doing business”, when in fact this cost can be easily avoided.

The effect of counterfeit components on products

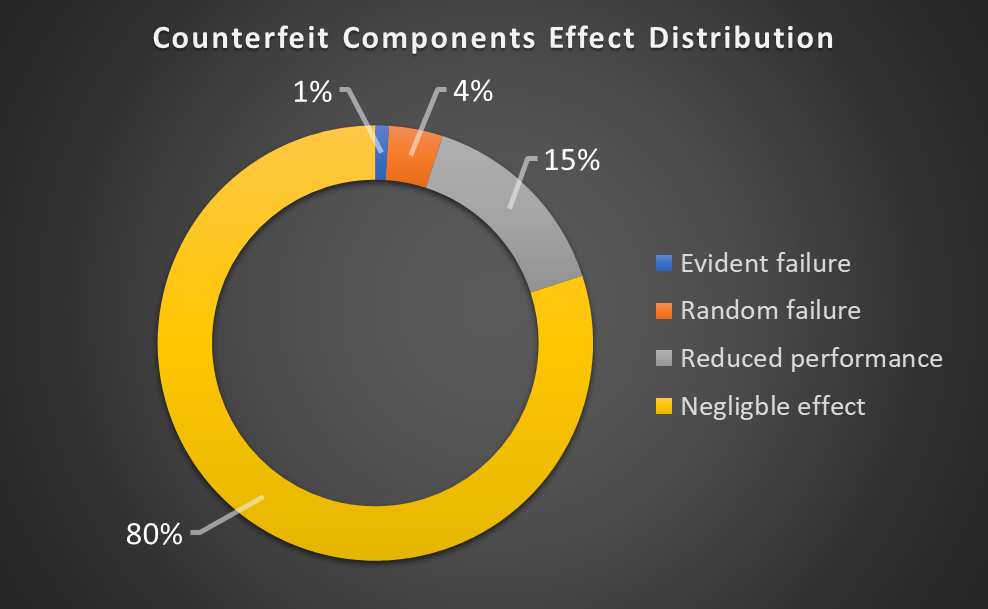

In most cases, counterfeit components have a negligible effect on quality. However, in approximately 15% of the cases, the product’s performance parameters will deteriorate, affecting lifetime, resilience, sensitivity to the environment, load, etc. In about 4%, it will cause unpredictable and random statistical failures that are extremely difficult to detect by conventional acceptance tests. They are difficult to pinpoint and are in most cases dismissed as workmanship issues. Occasionally, counterfeit components cause evident failure leading to massive recalls.

Random and evident failures are responsible for more than 30% of the product recalls. In about 70% of the cases, a rework of the faulty component fixes the product. Leading to misdiagnosing the inferior counterfeit soldering leads with assembly workmanship.

Current mitigation is to buy components from trusted sources or send components to labs. Lab testing is expensive and slow and ineffective because only small samples (~0.1%) are tested where batches are a mix of authentic and fraud components.

Cybord and Siemens’ collaboration for improved traceability

Cybord’s AI-based, big-data powered software manages real-time detection of malicious code-infested and counterfeit components. Cybord’s solution scans 100% of the components during assembly without delays, assuring that only authentic, fresh and untampered components get into your product.

Siemens Opcenter Execution Electronics and Cybord are working on a solution which brings the traceability to a new level the industry has never known:

- Siemens Opcenter Execution Electronics is connected to the SMT machines, collecting real-time data about each placement

- Cybord real-time service analyzes component images and meta-data of all the components during assembly identifying authenticity and malware

- Siemens Opcenter Intelligence provides reports and analysis on top of this new trace data

Traceability is supported in electronics manufacturing, but only to a certain degree. With this exciting collaboration, you will have certainty on what is placed on your PCB.

Zeev Efrat is an entrepreneur and business development expert deeply involved in initial market penetration and investment process. Managed several successful multinational new technology initiatives. Established Frost & Sullivan’s Israel as a leading consultancy firm.

Dr. Eyal Weiss, specializes in multidisciplinary technology. Awards and accolades winner in the fields of machine learning, plasma physics, laser technology and electromagnetics, including the prestigious “Innovation award”,” and “Pras-Bitchon-Israel 2018, 2019”.

In February 2020 Cybord participated in an Industry Innovation Tour by Siemens Dynamo in Tel-Aviv. You can visit the tour virtually here.