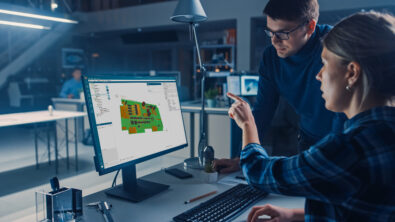

Intelligent PCB Layer Detection System: A Game Changer for Process Engineers

In the fast-paced world of Printed Circuit Board (PCB) design, efficiency and accuracy are paramount. Today, we’re excited to introduce a groundbreaking innovation that promises to transform the way process engineers work with PCB layers. Siemens has developed an intelligent PCB layer detection system that leverages machine learning to dramatically reduce the time and expertise required for PCB data preparation in tools like Process Preparation X.

The Challenge: Time-Consuming and Tedious Process

Traditionally, when importing Gerber data into CAD applications like Process Preparation X, users faced a laborious and time-consuming task. They had to manually classify each PCB design layer, setting correct values for “Context,” “Layer Type,” and “Side.” This process, which could take anywhere from a few minutes to tens of minutes depending on the size of the dataset and the user’s experience, not only required deep domain expertise but also consumed valuable engineering time that could be better spent on other work.

The Solution: Machine Learning Meets PCB Design

Siemens’ innovative AI-powered approach uses machine learning techniques to automatically suggest these layer properties, significantly reducing the manual effort required. Here’s how it works:

Intelligent Feature Engineering: The system extracts detailed counts of different characteristics in the layers, creating a rich set of features for the machine learning models to analyze.

High Accuracy: The best model achieves close to 95% accuracy* across all Layer Types, demonstrating its reliability and effectiveness. *Note: Accuracy may vary based on the dataset.

Key Benefits:

• Reduced User Domain Knowledge Requirements: The system minimizes the need for extensive PCB layer domain knowledge, making it easier for new users to get started and streamlining the learning process when using tools like Process Preparation X.

• Increased Process Automation: By automatically proposing layer properties in Process Preparation X, the invention saves users countless mouse clicks and significantly reduces the time spent on data preparation.

• Improved Accuracy and Reduced Errors: With less manual input, the chance for errors in classification is greatly reduced, ensuring more reliable data for the design process in Process Preparation X.

• Sustainability Impact: By automating time-intensive processes in tools like Process Preparation X, the system contributes to sustainability efforts by reducing energy consumption associated with manual tasks and improving overall resource efficiency in the PCB manufacturing process.

Real-World Impact: In a trial conducted by Siemens R&D, the Intelligent PCB layer detection system reduced the number of mouse clicks during the recognition process on average by 70% when using Process Preparation X—freeing up engineers to focus on other work rather than time-consuming manual tasks. The automated system also resulted in fewer errors, which ultimately improved the quality of the final product.

Ready to Transform Your PCB Data Preparation in Process Preparation X? Learn how Siemens’ Intelligent PCB Layer Detection System can boost your team’s efficiency, accuracy, and sustainability efforts when working with PCB data in tools like Process Preparation X. Contact us today for a demo or to discuss how it can be integrated into your workflow.

Learn more about how manufacturing AI is transforming engineering, production and supply chains.