Enhancing Automated Optical Inspection with Siemens’ Valor Process Preparation

As technology continues to advance, the demand for streamlined processes that can handle complex designs and diverse product types is ever-increasing. MIRTEC, a renowned specialist in optical inspection solutions, has recognized this need and taken a significant step forward by integrating Siemens’ Valor™ Process Preparation software into its automated optical inspection (AOI) and solder paste inspection (SPI) machines.

Complexity in Manufacturing Processes

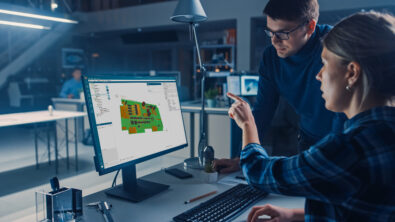

Electronic manufacturing services providers and contract manufacturers often face challenges in adapting to high-mix environments. With varying design formats and data sources like Gerber and ODB++, programming AOI and SPI machines manually can be time-consuming and prone to errors. The need for a seamless transition from design to programming is critical to optimize production efficiency and maintain high-quality standards.

The Solution: MIRTEC’s Collaboration with Siemens

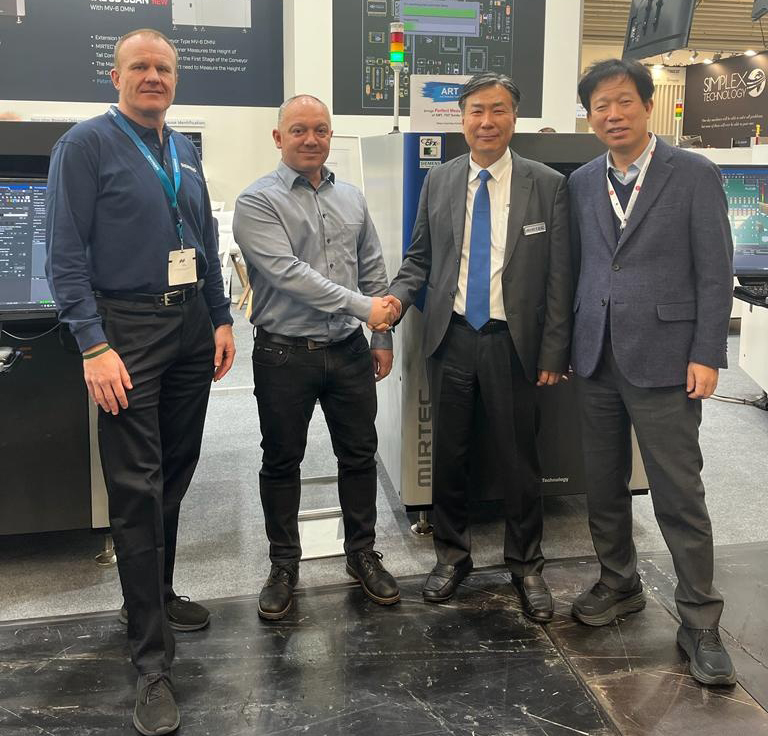

Through a strategic global partnership, MIRTEC has joined forces with Siemens Digital Industries Software to leverage the advanced capabilities of Valor Process Preparation. This integration allows MIRTEC’s customers to streamline the programming of AOI/SPI machines, facilitating accurate inspection programming directly from design files. By automating this process, MIRTEC aims to enhance manufacturing productivity and elevate the new product introduction (NPI) process to unprecedented levels of efficiency.

Streamlining Programming for Enhanced Efficiency

Valor Process Preparation from Siemens supports a wide range of assembly machines and product types. It empowers electronics manufacturers to automate and simplify programming tasks, reducing the time and effort required to set up inspection equipment. This automation not only saves valuable time but also minimizes the potential for errors that could impact production quality.

The Impact: Elevating Manufacturing Standards

The collaboration between MIRTEC and Siemens brings tangible benefits to electronics engineers and manufacturers worldwide. By embracing digitalization and automation, the need for physical assembled boards for programming inspection equipment is eliminated. This not only accelerates the programming phase but also optimizes the overall quality output, reducing debugging time and enhancing operational efficiency.

Customer-Centric Approach

Chanhwa Park, CEO of MIRTEC, underscores the significance of this partnership in delivering consistent and reliable solutions globally. The combined offering of MIRTEC’s industry-leading machines with Siemens’ Valor Process Preparation software instills confidence in customers, reaffirming MIRTEC’s commitment to meeting the evolving needs of electronics manufacturers.

Final Thoughts

In conclusion, the integration of Siemens’ Valor Process Preparation software with MIRTEC’s AOI and SPI machines marks a significant advancement in electronics manufacturing. This collaboration underscores a commitment to innovation and efficiency, empowering manufacturers to navigate high-mix environments with greater ease and precision. As technology continues to evolve, partnerships like these pave the way for enhanced productivity and quality in the realm of automated optical inspection.

Learn more about Mirtec:

MIRTEC Official Homepage (English Site): MIRTEC

MIRTEC Official Homepage (Korean Site): 미르기술 (mirtec.com)

MIRTEC Official Homepage (German Site): MIRTEC