How to cut new product introduction (NPI) time by 75%

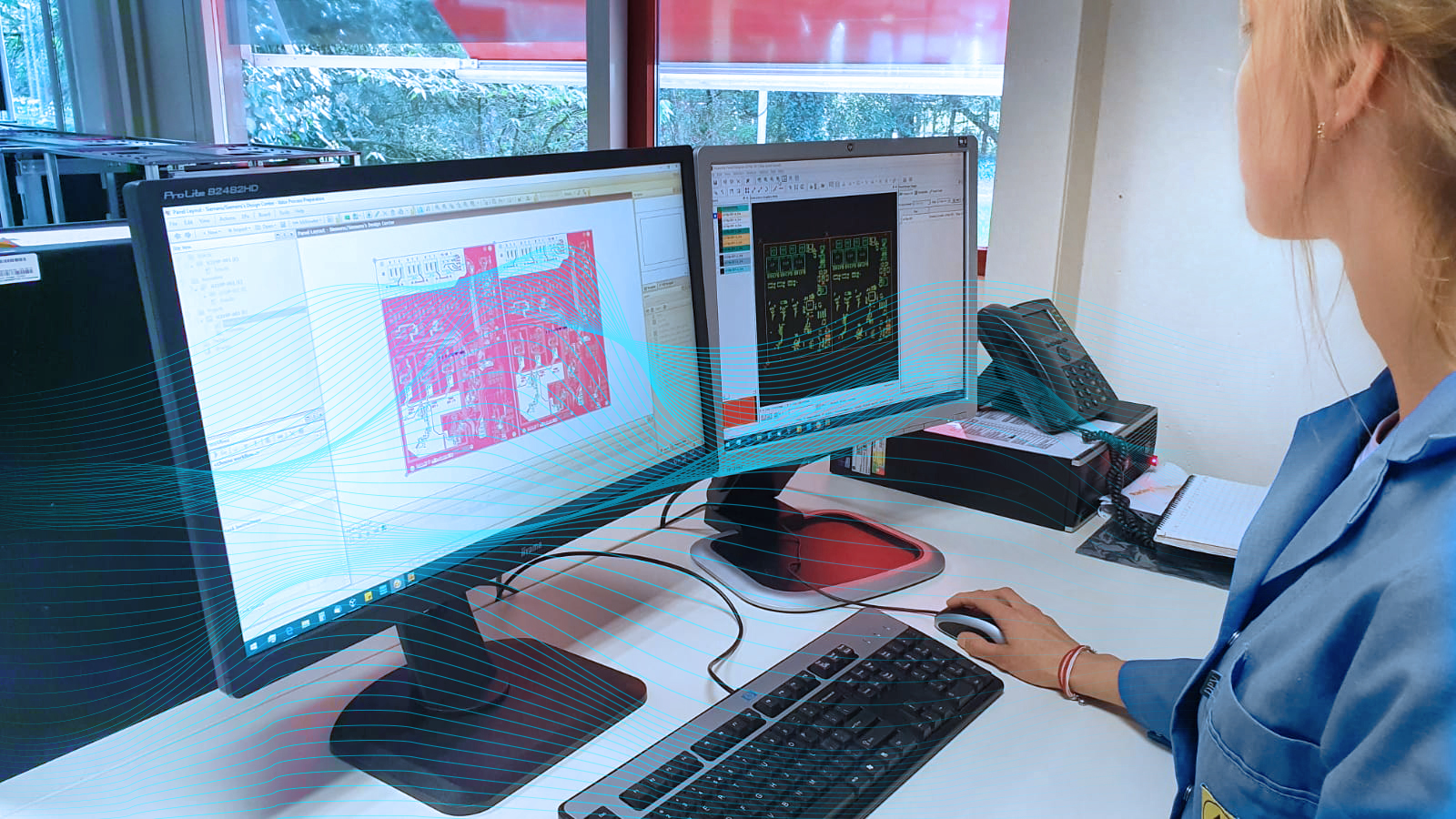

Phuntronix B.V. is an international Printer Circuit Board (PCB) assembly manufacturer based in the Netherlands. With a fully-automated SMT line that positions up to 100,000 components per hour, Phuntronix provides high-quality manufacturing services for the automotive, medical, defense/security, industrial/robotics, retail, and other industries.

Seeking a way to minimize the time-consuming new product introduction process, Phuntronix looked into a variety of market solutions, but could not find one that met their requirements. They needed worry-free, reliable software that would upload data, design panels, create machine programs, make drawings, upload BOMs, and basically conduct their entire, customized process preparation.

Improving processes with Valor

When they discovered Valor Process Preparation, they knew they had exactly what they were looking for. Using Valor Process Preparation, processes have improved, manpower can be utilized more effectively, customers receive top quality products and Phuntronix has succeeded in reducing their NPI time by 75%, from two-and-a-half days to just half a day.

Want to learn how they did it? Read the full case study for insights on how Phuntronix used Siemens’ software to improve results, and discover the keys to their success.

Valor Process Preparation available now in 30-day free trial>>