Valor Parts Library: What You Need to Know

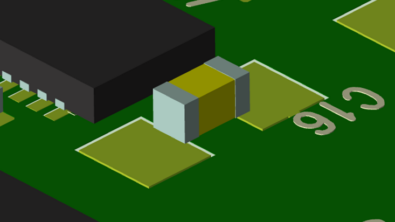

Validating the PCB footprint with a comprehensive component library

Are you familiar with the Valor Parts Library? Whether you are experienced with Valor Parts Library (VPL) or this is your first exposure, I’d like to invite you to download this white paper, published recently, which provides valuable insight into using this comprehensive component library in the design-for-manufacturing (DFM) handoff process.

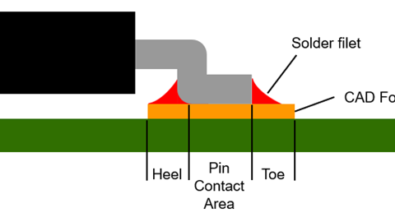

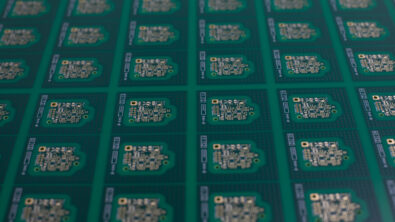

DFM analysis depends heavily on the electronics part data for the design – or its PCB footprint. VPL is a critical component for performing manufacturability analysis that results in better quality PCBs, which can be readily manufactured. No other component library available contains anywhere near the number of parts that have complete geometric representation within VPL – over a billion parts!

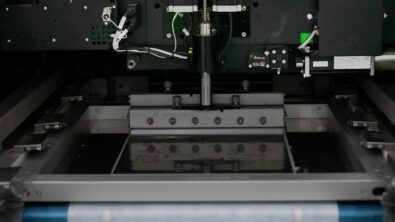

VPL addresses many of the industry’s challenges, and it is an important tool in the design-to-manufacturing flow. Coupling VPL with Valor NPI DFM software lets you run thorough manufacturability analyses during all stages of the design to detect errors at the earliest possible stage.

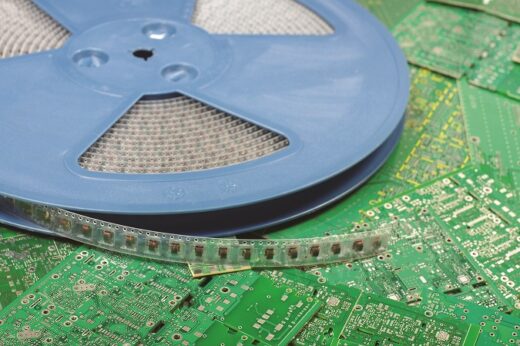

Accurate PCB footprint role in lowering production costs

Discovering and correcting issues that can potentially exceed the project budget and/or miss schedule deadlines not only saves time and money that would be spent re-spinning the board, it also allows your company to recognize revenue on the product much earlier.

Download the white paper Valor Parts Library enhances DFM for designing better quality PCBs to learn more about the use of this complete PCB footprint library.