What will it take to build the heavy equipment machines of the future?

Using today’s software to create tomorrow’s heavy equipment

Technology is changing rapidly in the heavy equipment industry. From mining to construction to agriculture, heavy equipment builders must be aware of the developments in their industry and how critical it is to have the right design and simulation tools to bring their products to market in the shortest time possible.

For heavy equipment manufacturers, integrating more technology to differentiate products means increased complexity. On top of that, customers are more demanding and sophisticated — they want to rapidly adopt automotive-type capabilities such as economy and creature comforts, which means higher levels of customization.

Unfortunately, too many manufacturers use yesterday’s design tools to create today’s machines, and those tactics simply aren’t up to the task. With mechanical, electrical and software engineering teams often scattered across departments and across the globe, there are too many points where information must be shared between disciplines without the luxury of time to work sequentially through the product.

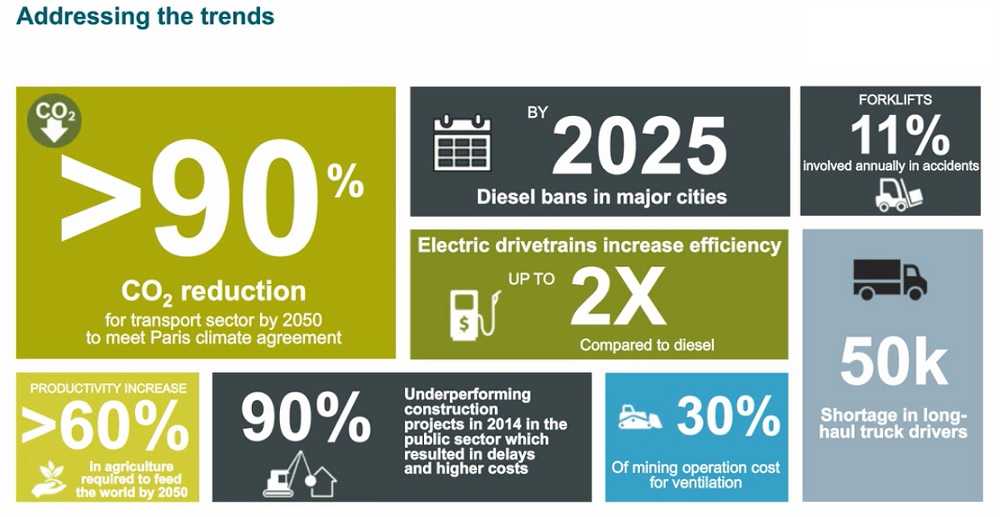

The trends reinforcing the need for a digitalization strategy

The global market for heavy equipment is estimated at $500 billion; experts forecast continued market growth. With a market that size, and understanding the cyclical nature of the industry itself, it’s easy to see why companies are adopting a strategy of greater globalization and a pattern of consolidation of local companies.

Forming larger companies with a global presence is a strategic way to manage risk in cyclic markets while bringing the best machines to the most appropriate markets at the lowest costs. These entities are trying to accomplish cost management by combining common designs with regionalization and local manufacturing strategies.

The U.N. projects a global population of 8.5 billion by 2030. Because a growing population requires more nutrition, farmers are tasked with feeding more people with the same field and fewer workers. Therefore, the need for greater efficiency and automation in farming equipment is high.

Manufacturers aim to build durable machines that last decades. In that time frame there are likely multiple improvements to the base machine, electrification and connectivity technology platforms. These improvements occur in three complex areas: mechanical durability, change in controls technology and the multiple upgrade paths for your customers. This continues to make managing services and spare parts a challenge.

Let’s take a tractor as an example when it comes to looking at these trends. We can assume the base mechanical tractor hasn’t changed much in the last 20 years, yet the increased use of software, sensors and smart devices have created more product revisions in that tractor than the normal reliability growth. Every cylinder, valve and hydraulic pump is equipped with extensive monitoring sensors and controls. Systems are more integrated now than ever before.

When you focus on tomorrow with advanced technologies, manufacturers can utilize algorithms and gather input to make sure the tractor adapts to its conditions, wherever it is being used.

Building these machines with the right digitalization tools means the design can take place with global engineering teams all looking at different disciplines, such as electrical, mechanical, hydraulic and simulation. These teams must have access to the same data and collaborate with the same information. Changes and enhancements should be able to be implemented from anywhere to accommodate region-specific market conditions and governmental regulations can. AGCO, a global leader in design, manufactures and distributes agricultural solutions and met this challenge by implementing a design anywhere, build anywhere strategy. By using comprehensive software solutions as part of the Xcelerator portfolio, AGCO took the rich data created by design and could share it with different users in manufacturing at multiple sites around the world.

“In the case of design anywhere, build anywhere, all of our new product introductions are going to be platform-oriented, and will re-use data” – Gary D’Souza, manufacturing engineering lead, global manufacturing PLM at AGCO.

Read about their successes here.

Sustainability as a trend

Urbanization is increasing at a dramatic rate and countries are pressuring companies to build more efficient vehicles, even banning diesel engines in some metropolitan cities. From emissions to safety, there is no shortage of regulatory environments, which often vary from country-to-country while corporate standards vary from company-to-company.

How will regional regulations and sustainability impact machine designs?

Sustainability often means fuel economy and emissions, but that’s only part of it. We need to think more than just efficiency but also the environment in which it operates. Consider the effects of a diesel engine being used in a mine shaft where ventilation and shafts are the means for air. Sustainability in a mine operation can take the form of an electric vehicle that’s user-friendly and cost-effective while autonomy removes the operator altogether.

Being able to simulate these environments, automate and electrify makes sense and enhances user experience.

Owners are looking to reduce cost of ownership through reduction or removal of harm, unplanned downtime and emissions. The goal is to reduce these to zero. How so?

- Zero harm. Using electrification, automation and intelligent sensors to detect hazardous conditions and override the operator stopping a vehicle short of damage. This interconnected worksite means better operator information and coordination while reducing the possibility of operator harm.

- Zero unplanned downtime. Leveraging advanced simulation and validation processes, especially those related to durability provides machinery with optimal uptime. Utilizing software and sensor-driven operation can help keep machines operating within its original design parameters and extend the useful life of the machine. Those same sensors can extend the machine’s service operation.

- Zero emissions. With a name like heavy equipment weight is a factor. Lightweight designs and innovative powertrains as well as simulation and verification can help reduce emissions and improve fuel economy which lowers the total cost of operation.

Digitalization changes everything

Many heavy equipment manufacturing companies have adopted some digitalization in their own spaces, for example to measure the health of an individual plant or diagnosing fertilization and hydration requirements. Even real-time or just-in-time deliveries involve digitalization. Your ability to leverage digitalization can very well determine your company’s ability to survive.

The answer to face these challenges involves design and simulation software which removes the boundaries between engineering disciplines. It lets teams collaborate with a single unified model and brings all these disciplines together with a single digitalization strategy.

The concludes the first blog in the series. As we continue discussing the trends and challenges facing the heavy equipment industry, we’ll see how manufacturers are using simulation, validation and digital tools to help build tomorrow’s machines.

Click here to learn more how the Xcelerator Portfolio is revolutionizing the way heavy equipment manufacturers are designing, building and competing.

Comments