The digital twin offers solutions to CNC machining challenges across industries

Manufacturers that utilize CNC machines are under constant pressure by their industries, which continually demand more efficient operations and higher product quality. All the while, the manufacturers face their own sets of challenges. The specific challenges depend on the industry and products the manufacturer works on, with job shops requiring flexible processes and fast, accurate verification, while environments working with complex parts need efficient, high-precision cutting conditions.

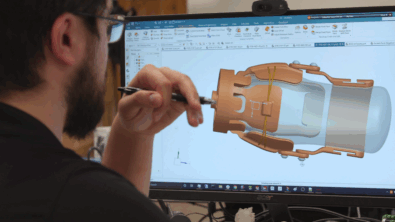

Despite the breadth of challenges faced by CNC manufacturers across industries, solutions to all of them can be found in digital transformation, and more specifically, the digital twin. As the virtual representation of a physical object or process, the digital twin is capable of providing detailed simulations of CNC processes, providing key insights to machine tool performance before ever carrying them out physically. With the digital twin, CNC manufacturers of all stripes can overcome their obstacles and ensure their operations are safer and more efficient.

Job shops: High flexibility and fast turnaround

Job shops have their own unique challenges as a result of high variability between products they make and their fast-paced environments. Their focus on small-batch production for a wide variety of products requires multiple changeovers between parts and tools, in addition to new CNC programs. To keep up with demand, job shop operators often program the CNC machine directly, which allows for flexibility but also increases the chances of error in setup, tool selection, or programming, leading to collisions that can raise costs and delay production.

The fast-paced environments of job shops also demands quick verification processes. However, many verification processes are done manually with dry runs or step-by-step executions, which can be slow. Due to limited time to test programs, operators might miss errors until machining begins, which can lead to scrapped parts and damage to tools and machines. Having a digital tool that can find such errors and finish processes earlier can significantly help job shops meet their demands.

Complex industry: High precision and efficiency

Manufacturers for industries such as aerospace, heavy machinery, automotive, and medical, meanwhile, deal with their own set of issues centered around precision, repeatability, and compliance. Parts designed for these industries, such as engine turbines and electric motors, are complex in design and often utilize expensive materials. As such, the CNC processes used to machine them require a higher degree of precision, utilizing highly optimized toolpaths and real-time monitoring, lest a single error result in thousands of dollars of damage and delays.

Furthermore, some of these industries also have to contend with their own specific considerations. Aerospace manufacturers need to comply with heavy regulations that require detailed documentation throughout the machining process. Automotive and medical products are typically designed for automated, mass production and need easily repeatable machining processes as well as sufficient pretesting. Simulation and analysis tools, therefore, would be critical in ensuring products for these industries are well-machined and the processes to make them are optimized and efficient.

Finding solutions in the digital twin

Such capabilities can be found with the digital twin, and they can be used to overcome challenges across industries. CNC users can use the digital twin to design, simulate, and optimize components and tools virtually, where they can complete development and validation work faster and save time and resources on future processes.

These simulations, which can be as basic or detailed according to the CNC user’s needs, provide a safe environment to identify errors, analyze complex interactions, and optimize whole processes without ever risking physical equipment. Their environments enable users to accurately assess programs before beginning production and answer critical questions about production time and manufacturability, great benefits for both job shops and manufacturers of complex products.

With an accurate, one-to-one digital twin of a CNC machine, manufacturers can ensure their processes are safe, efficient, and optimized before ever carrying out physical machining operations. These solutions can be applied anywhere, whether in the fast-paced, highly variable job shop, or the manufacturer of complex components in need of high-precision machining. No matter the field, the digital twin can overcome today’s biggest challenges in CNC machining.

To learn more about the digital twin’s role in CNC machining, check out this article.

Siemens Digital Industries Software helps organizations of all sizes digitally transform using software, hardware and services from the Siemens Xcelerator business platform. Siemens’ software and the comprehensive digital twin enable companies to optimize their design, engineering and manufacturing processes to turn today’s ideas into the sustainable products of the future. From chips to entire systems, from product to process, across all industries. Siemens Digital Industries Software – Accelerating transformation.