More Perspectives on the Shift-Left and the Comprehensive Digital Twin with Mike Crist and Scot Morrison – Part 3 – Summary

In a recent series on the Industry Forward Podcast, Dale and I sat down with Mike Crist and Scot Morrison to explore how aerospace and other companies are adapting to the rapid shift towards software-defined product development. You can listen to the third and final part of that discussion through the player, or read a summary below.

Shift-Left with AI in Software and Hardware Development

The conversation began with a look at how artificial intelligence is impacting development workflows. Scot Morrison explained that AI adoption started with analysis: “Initially, a lot of it started with static analysis and in some cases even dynamic analysis during execution of software.” These tools improved productivity by making testing more efficient.

Now, AI is moving into development itself. “Authoring has IP concerns,” Morrison noted, “but people are building up knowledge bases internally to leverage the vast amount of experience they have.” Large organizations are using internal data to create inference engines that assist developers with authoring, testing, and integration—accelerating the entire software lifecycle.

The Power of Embracing Change During a Digital Shift

Even as companies recognize the advantages of digitalization and a shift-left approach to system development, such change can be difficult for companies to embrace. Mike shared an anecdote illustrating how difficult it can be for companies to embrace new business models, even when such change can unlock significant gains. His brother, a software architect for a freight management company, developed a platform that could have been commercialized, opening up entirely new revenue streams for the company. “They could have become a software company and made much more money selling software than moving freight,” Crist said. But leadership couldn’t make the shift—and ultimately let his brother go.

Mike emphasized that this resistance to change isn’t unique to a single industry or sector: “That struggle companies have isn’t unique to aerospace, defense, or auto.” It’s a reminder that digital transformation often requires rethinking long-held assumptions about value creation and a commitment to long-term investment.

Companies may see the potential value of digitalization and shifting-left, but the effort and cost involved in the change remains an obstacle. With that in mind, the discussion turned to shift-left strategies and whether they imply a complete move to virtual testing. Dale Tutt asked how companies are responding to the process and cultural shift away from physical testing for certification.

Crist responded with a story: “We were in a meeting trying to apply Agile software development to hardware development. One mechanical engineer said, ‘Software delivers features every two weeks. What do you expect us to do—cut metal?’” Of course, digital tools could be used in this scenario to ensure that mechanical designs remain up-to-date with the latest from the software teams, but sometimes important context is missed on a computer screen. Instead, the team improvised by creating a cardboard mock-up in the break room. “That let us answer design questions we couldn’t easily address in CAD,” Crist explained. Ultimately, shift-left is not about going fully virtual in all situations. Rather, companies should focus on using the right model for the question at hand. Sometimes that’s a high-fidelity simulation; other times, it’s a physical mock-up.

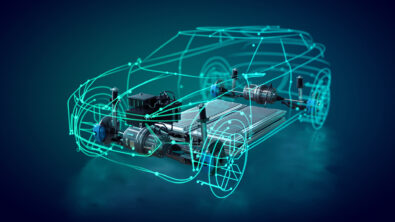

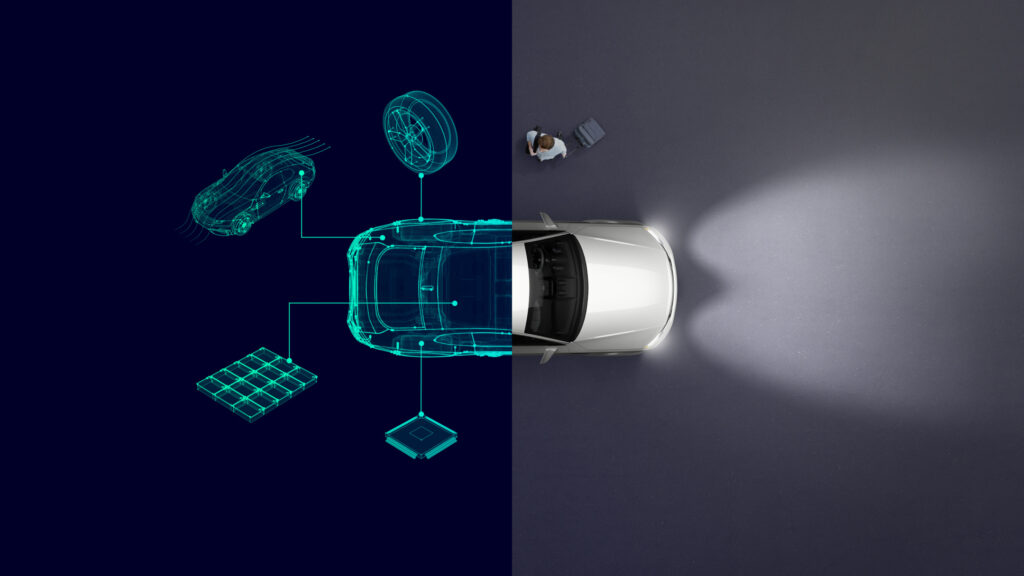

The Role of Digital Twins in Development

Virtual tools are still crucial and offer significant advantages in cost, flexibility, and speed. Scot shared an example from a top-five OEM: “They pointed to a hardware rig used for validation and said, ‘We want to replace that with a virtual equivalent.’” The cost and complexity of the physical rig made virtual alternatives attractive for this OEM.

However, Morrison cautioned that a hybrid approach is often necessary: “Safety systems may still require full hardware testing. There’s a continuum in development.” The goal is to build solutions that support the entire flow, not just isolated components.

Dale Tutt tied this back to the importance of a comprehensive digital twin: “It really emphasizes how critical a comprehensive digital twin is—connecting across domains so you can understand your system, perform virtual verification, and even use cardboard mock-ups if needed.”

Embracing Change and Navigating the Journey of Digitalization

As the episode wrapped up, Mike encouraged companies to challenge assumptions: “Disruptors take niche applications or approaches and turn them mainstream. They break away from long-held beliefs about how things ‘should’ be.”

Morrison added that transformation is a journey: “You can’t drop in a new development flow without understanding where they are and what their goals are. Our job is to be part of that journey—identify high-value, easy-to-adopt steps and guide them.”

Tutt summarized the series by highlighting the themes of complexity, collaboration, and digital transformation: “This is an ecosystem, and bringing everything together with our customers is vital.”

Siemens Digital Industries Software helps organizations of all sizes digitally transform using software, hardware and services from the Siemens Xcelerator business platform. Siemens’ software and the comprehensive digital twin enable companies to optimize their design, engineering and manufacturing processes to turn today’s ideas into the sustainable products of the future. From chips to entire systems, from product to process, across all industries. Siemens Digital Industries Software – Accelerating transformation.