Perfecting the driving experience

Transportation is a part of daily life for most, but its definition is beginning to change. Electrification, advanced driver assistance systems (ADAS) and autonomous driving technologies are creating new travel experiences for drivers and passengers. The growth in global population and urban centers creates the need for smoother traffic flows and more clean transportation. Nowhere is this more true than in India.

To meet the challenges of urbanization and its effects on roads, the Indian National government has teamed up with a number of regional governments and the Indian automotive industry. The result of this unique collaboration is the formation of the National Automotive Testing and R&D Infrastructure Project (NATRiP). The goal is to construct state-of-the-art testing, validation and R&D infrastructure in India. By providing modern infrastructure for design, development and testing of components and full vehicles, the project looks to grow the Indian automotive sector in the short-term. And in the long-term, the project will establish Indian service providers as leading partners on a global scale.

Part of establishing NATRiP was the creation of the International Centre for Automotive Technology (ICAT), which has two facilities in Manesar, Haryana, India providing access to services supporting the automotive industry across multiple domains. While the services available cover everything from design and simulation to fatigue testing and safety improvement, the foremost capability of the newest facility is the advanced noise, vibration and harshness (NVH) laboratory.

World-class NVH facility

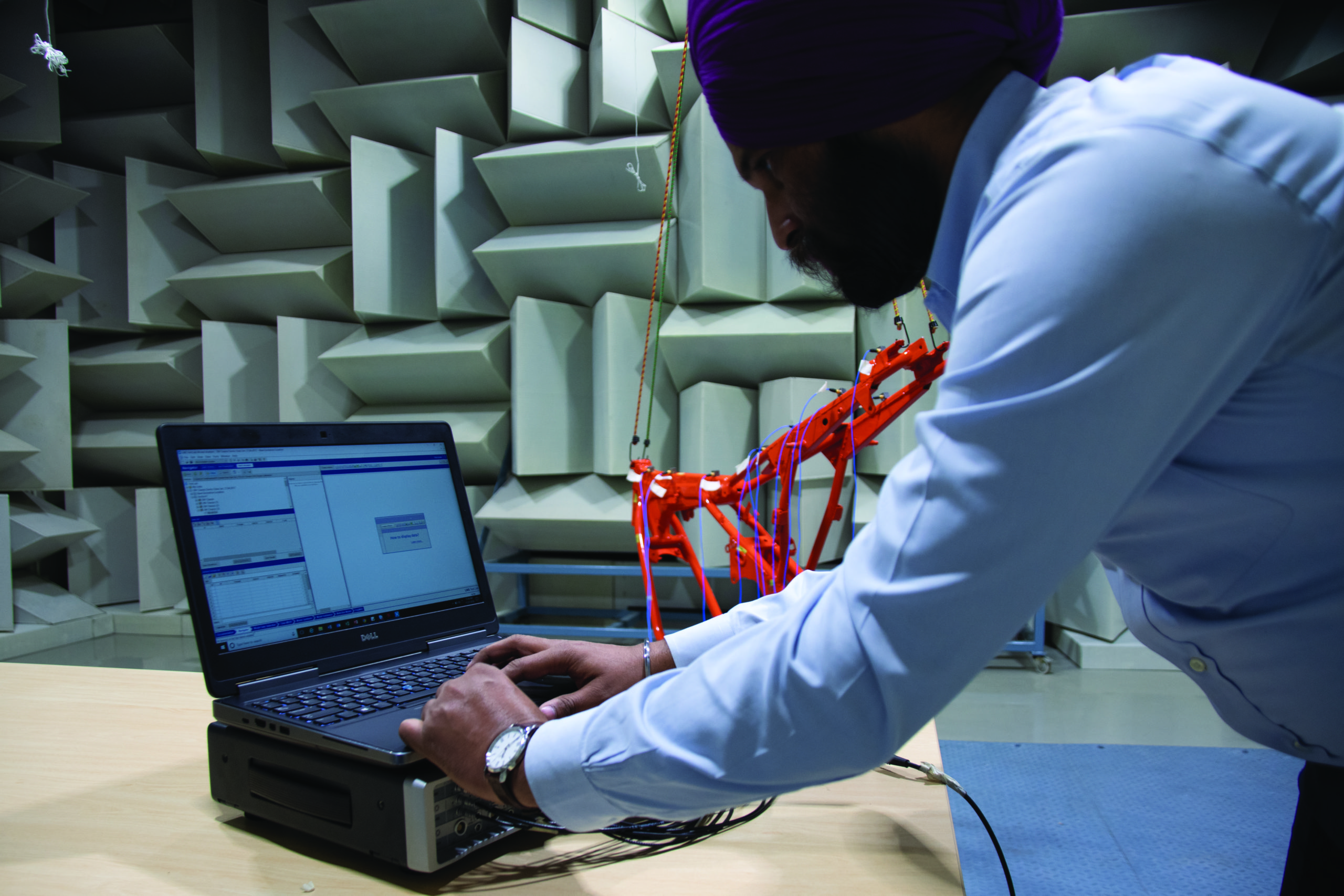

Nearly $22 million was invested in the new facility housing the NVH laboratory along with an electromagnetic compatibility (EMC) lab, passive safety lab and a tire testing lab. The site includes several semi-anechoic chambers with dynamometers suited to all vehicles from motorcycles and passenger cars to buses, trucks and tractors. The largest chamber enables vehicle manufacturers to perform indoor pass-by noise tests in the room and ensure the test vehicles will meet noise-level regulations and homologation standards. Smaller labs on-site enable modal testing and analysis to understand sound transmission loss and absorption coefficient testing of different materials and shapes.

Along with the standard NVH optimizations that would be performed on internal combustion vehicles like tire rumble and wind noise, hybrid and all-electric vehicles undergo further noise reduction. Without the constant drone of an internal combustion engine, the buzzing, squeaks and rattling of the vehicle are far more perceptible to the human ear. Using source localization tools and acoustic cameras, the noise sources can be isolated and re-engineered to eliminate the problem and deliver the best product to the customer.

Fully featured simulation package

When tasked with equipping the new testing facility, the lab manager looked to Siemens’ Simcenter™, part of the Xcelerator portfolio, for integrated software and hardware deployments to cover NVH assessment, modal analysis, and sound identification. With the help of the Simcenter™ portfolio of testing solutions, ICAT offers services and expertise for vehicle engineering, validation and testing with comprehensive, up-to-date accredited testing facilities. The NVH lab is suited for homologation and certification of all types of vehicles, from two-wheelers to buses, trucks and tractors. The test tracks and the large semi-anechoic chambers welcome heavy equipment machines such as construction equipment vehicles. Building facilities for the auto industry of tomorrow

The International Centre for Automotive Technology hopes to aid the growing automotive market over the next decade. According to ICATs director, Dinesh Tyagi, “[i]t is expected that by the year 2030, the four-wheeler market will cross the 10 million units mark.” Adding in the even larger two-wheeled market Tyagi commented, “we expect to see some 40 to 50 million vehicle units in circulation.” ICAT has invested $8 million in its facilities every year to meet the projected demand for development and help manufacturers meet environmental constraints and customer. The International Centre for Automotive Technology’s world class testing facilities, with the help of Siemens Digital Industries Software, is where today meets tomorrow in creating the perfect urbandriving experience.

To learn more on how the International Centre for Automotive Technology is positioning India as a global leader in the automotive sector, check them out here: International Centre for Automotive Technology