How the production digital twin prepares aerospace manufacturers for the future

Factories consist of numerous moving parts and processes that serve the assembly of new products. As a result, there is considerable risk when manufacturers enact new manufacturing strategies, whether they include the design and construction of new factories or refit existing factories to align with new goals. There is always a chance that manufacturers might encounter an error long after construction is finished or an assembly line is not as optimized as it could be, forcing the manufacturer to spend even more time and resources to make corrections.

These are the kinds of risks being faced by aerospace manufacturers today as they rework their production processes to accommodate new classes of aircraft and spacecraft. Historically, the aerospace and defense (A&D) industry has worked with commercial airliners, jets, and rockets, high-value products typically made in low volumes. However, as new products such as drones and satellites become cheaper to make and rise in popularity, there is increasing demand to shift A&D manufacturing processes to produce these crafts in higher volumes.

To meet these demands while avoiding potential pitfalls in reforming their strategies, aerospace manufacturers can benefit from gaining key insights into their strategies before laying their first foundation in the physical world. Such insights can be provided by the production digital twin.

Defining the production digital twin

To understand the production digital twin, one must first understand the larger tool it’s a part of, known as the comprehensive digital twin. This is the virtual representation of a product, process, or system across its entire lifecycle, from the earliest design phase all the way to operation. It helps bridge the gaps between silos and fosters traceability and collaboration across engineering domains.

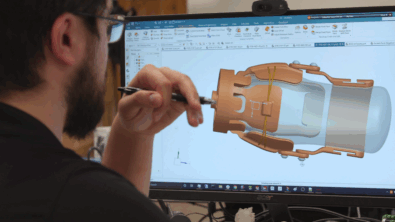

The production digital twin, as suggested by its name, represents the production aspects of the lifecycle, including everything from individual assembly lines to an entire factory, even human workers and their interactions with onsite equipment. By leveraging real-time data from multiple domains, engineers can model and simulate any kind of production process in a digital environment. This grants key insights about new production processes before they are ever carried out in the physical world.

Optimizing aerospace factories

The benefits of these insights from the production digital twin also stretch across the factory’s lifecycle.

To begin with, the production digital twin helps uncover potential errors sooner rather than later. Engineers can model their factory plan and then test it under multiple different scenarios, enabling them to fix the errors virtually and avoiding spending additional time and money to find and correct them after physical construction. Furthermore, these simulations can be run under various key performance indicators (KPIs) such as production efficiency and supply chain delivery, as well as other financial and technical requirements to optimize production processes for a company’s goals.

After design and construction, the production digital twin continues to provide benefits through the operation of factories and their processes too. IoT (Internet of Things) sensors can be installed in factory equipment and machinery to feed real-time data back into the digital twin for analysis. It can then use this data to identify inefficiency or areas affected by issues such as supply chain shortages, forecast their effects on production, and suggest solutions. The production digital twin ensures manufacturers are operating their factories at peak performance as much as possible.

The A&D industry is in a prime state to make great use of the production digital twin. Not only is there enormous amounts of money being invested in the production of existing aircraft, but new aircraft such as drones and satellites, ideal for high-volume production, are also rising in demand. Manufacturers for the industry need to adapt their processes to meet these trends, which will involve numerous decisions involving new technologies, new strategies, and the work of people. The production digital twin will be an invaluable tool for manufacturers to navigate all these questions and challenges, ensuring their factories and production processes, new or refitted, are ready meet the demands of both the present and the future.

For more information on the production digital twin in A&D, check out this article.

Siemens Digital Industries Software helps organizations of all sizes digitally transform using software, hardware and services from the Siemens Xcelerator business platform. Siemens’ software and the comprehensive digital twin enable companies to optimize their design, engineering and manufacturing processes to turn today’s ideas into the sustainable products of the future. From chips to entire systems, from product to process, across all industries. Siemens Digital Industries Software – Accelerating transformation.