Unlocking circularity with a digital-first approach

A lot can be done to make current economic models more sustainable. Much of today’s economy operates under a take-make-waste structure, where organizations across the globe extract finite resources, use them to create products and throw them away after their purpose ends. Not only is this methodology inefficient, but it also generates enormous amounts of waste and emissions that harm the environment, which in turn creates even more stress for supply chains and the global economy.

Fortunately, there is an alternative model, one that promotes the reusability and recycling of materials and grows sustainability alongside economic resilience. That model is known as circularity.

What is circularity?

Circularity is essentially the opposite of the take-make-waste model. Instead of throwing away materials and goods after they are used, circularity prioritizes their reuse, repair, remanufacturing and recycling, keeping them in use longer while decreasing organizations’ reliance on virgin extraction. For example, say a consumer is about to remove residences and has no more use for a piece of furniture, a table, perhaps. Under circularity, rather than simply disposing of the table, the consumer can send it back to the company that made it, where they can reuse its materials to manufacture newer products.

There are two key component models to make circularity successful. The first kind are material models, which govern the usage of physical material resources, goods, and energy, extending their lifespans as much as possible. The second kind are business models, which determine the transactions and monetary values needed to support the operation of the material models. This can include the implementation of new leasing or service models that help companies better monetize the residual value of a product when it reaches what people would consider its end of life.

The benefits of circularity go beyond simply protecting the environment. By reducing reliance on resource extraction and cutting down on waste, companies can bolster their supply chains and resource resilience, all the way to preparing for potential environmental regulations in the future and increasing their bottom line.

The challenges of circularity

Circularity is finding adoption among companies, those some adopt faster than others. According to a survey done by IDC, a market intelligence, data and events provider for the information technology, telecommunications, and consumer technology markets, among 500 businesses surveyed in the EMEA region, 44 percent do not have a circularity strategy or integrated circular practices in place. Additionally, 29 percent have a strategy or targets, but those plans are not comprehensive or holistic.

Of course, there are challenges to be expected in the transition to an entirely different way of doing business, which can hamper adoption rates. Many of them derive from the complexity of the requirements and processes that are involved, including the design of products for circularity, how companies recollect them, how they can be refurbished or remanufactured and more. The amount of decisions that go into products increases quite a bit.

Such decisions might be easier to accomplish with multiple companies working together rather than a single company trying to do everything. Therefore, building an ecosystem of partnerships is often seen as an attractive option for those building circularity. However, ecosystems come with their own complexities to overcome. The more players there are in the game, the likelihood of issues surrounding supply chains or data traceability across the product lifecycle between partners increases.

Digitalizing circularity

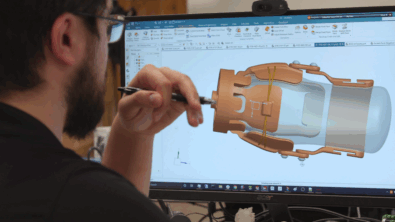

Digitalization is precisely what is needed to reduce such complexities and make circular models efficient and successful. For example, with more requirements being added to the equation, the more imperative it is those requirements be understood and integrated into their products as early as possible in the product lifecycle. Digital tools can be used to test and simulate products in the digital world before building them physically. This helps companies attain a better grasp of their new products and processes and make decisions based on better insights, all the while saving time and resources.

Furthermore, AI tools can reduce complexity and optimize processes even further. Products made for circularity are bound to generate great quantities of data across their lifecycle. AI can help with automating tasks such as gathering and transferring data to help engineers better manage and comprehend the data they need to work with. This is especially crucial in ecosystems, where data needs to be efficiently shared and understood across partners.

Circularity offers to transform how companies across the world manage their resources and products, building new models that promote sustainable practices while increasing their economic resiliency. Challenges are bound to arise in such a transition, but with the powerful tools and technologies provided by digitalization and AI, companies can be better equipped to navigate them and usher in a new, sustainable era for their economies.

Check out this webpage to learn more about circularity and examples in action.

Siemens Digital Industries Software helps organizations of all sizes digitally transform using software, hardware and services from the Siemens Xcelerator business platform. Siemens’ software and the comprehensive digital twin enable companies to optimize their design, engineering and manufacturing processes to turn today’s ideas into the sustainable products of the future. From chips to entire systems, from product to process, across all industries. Siemens Digital Industries Software – Accelerating transformation.