The rise of software-defined aerospace – Summary

One of the biggest drivers in the aerospace and defense (A&D) industry pushing the need for new, holistic forms of systems engineering is the increasing complexity of today’s aircraft and spacecraft. The introduction of new technologies and systems is introducing new considerations and potential oversights aerospace engineers need to account for, especially regarding electronics and software. Like many other industries, aerospace products are becoming more and more software-defined, and transforming systems engineering can help manage the complexities that come with that.

In the latest episode of Talking Aerospace Today, Todd Tuthill, Vice President of Aerospace, Defense, and Marine for Siemens Digital Industries Software, is joined again by Dale Tutt, Vice President of Industry Strategy for Siemens. They pick up from their discussion in the previous episode, discussing why holistic systems engineering is needed for software-defined aerospace products. They also talk about other aerospace challenges systems engineering can help with and what other industries can learn from aerospace’s experience with systems engineering.

Complexities in being software-defined

The presence of electronics, software, and avionics has been steadily increasing in aircraft and spacecraft over the past few decades, certainly nothing new. What has changed over the decades, however, is the levels of complexity and interfaces in these systems. More and more functions are being relegated to electronics or software, not only changing how things typically work in aerospace products, but also expanding the sheer number of things that can be done.

To demonstrate this, Dale points to the kinds of interactions aerospace engineers needed to handle twenty years ago. Back then, he says, engineers maybe only had to worry about maybe 100 interactions, all of which could be managed on a spreadsheet. These interactions would also like involve only mechanical systems, which could be easily understood. Today’s semiconductor chips, meanwhile, expand the number of operations and interactions into the hundreds of thousands. From a standpoint of system safety, a single chip might very well have over 90,000 failure modes inside.

Thus, traditional approaches to systems engineering need be changed to enable more cross-domain collaboration and integration, allowing aerospace engineers to better comprehend the sheer scale of interactions and complexities of their products.

Thinking past the launchpad

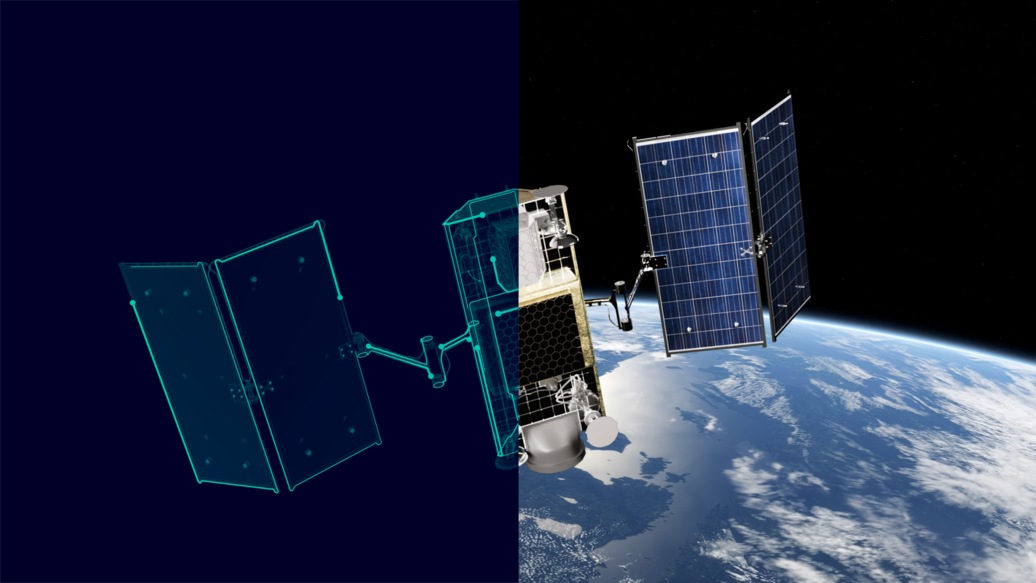

Todd points out another critical factor in aerospace, from the space sector specifically, that encourages holistic approaches to systems engineering, is thinking about the product’s end-of-life, whether it’s a rocket, satellite, or something else. Unlike the days of the Apollo Program, low Earth orbit is filled with thousands upon thousands, much of which is junk. If organizations want to be responsible in their space exploration, they need to plan for their products’ end-of-life, whether it takes the form of deorbiting satellites or making rockets reusable. Of course, there are no second chances once spacecraft leave the launchpad, so these considerations need to be addressed as early as possible in the product lifecycle.

Systems engineering beyond aerospace

Another topic discussed in this episode was what other industries can learn from A&D when it comes to systems engineering.

Todd emphasizes how great it is for planning more than just the good day scenarios. In addition to rising number of interactions within themselves, aircraft and spacecraft operate in some of the most strenuous environments, where many things can go wrong. The automotive industry faces similar challenges with self-driving vehicles, which have to account for a multitude of potential failures, perhaps too many to keep track of all at one. Systems engineering helps connect various aspects of the product lifecycle, making complex aspects like these easier to understand and account for.

Dale and Todd also focus on how systems engineering is not just for big projects, but for any project. Systems engineering at its core is about breaking down a product’s complexity in the most efficient way and bringing it all back together to solve a problem. Whether the project is as big as a mining excavator or as small as a smartphone, systems engineering can be an invaluable tool to codevelop all aspects of a product and make it the best it can be.

To learn more about systems engineering and how it can be used to improve aerospace and beyond, be sure to tune into more episodes of Talking Aerospace Today.

Siemens Digital Industries Software helps organizations of all sizes digitally transform using software, hardware and services from the Siemens Xcelerator business platform. Siemens’ software and the comprehensive digital twin enable companies to optimize their design, engineering and manufacturing processes to turn today’s ideas into the sustainable products of the future. From chips to entire systems, from product to process, across all industries. Siemens Digital Industries Software – Accelerating transformation.