Aerospace Factories of the Future – Summary

As the aerospace and defense (A&D) industry moves to increase its production volumes, especially for drones and uncrewed aircraft, new challenges stand in the way. Today’s traditional factories, many of which rely on touch labor, are not flexible enough to produce aircraft of such variety and modularity at desired scales. Fortunately, opportunities to leverage digital transformation and smart manufacturing exist, giving A&D manufacturers the chance to help the industry meet its goals.

In the latest episode of Talking Aerospace Today, Todd Tuthill, Vice President of Aerospace, Defense, and Marine for Siemens Digital Industries Software, continues the conversation from the previous episode on A&D’s movement toward higher volume production. After identifying the core drives and challenges behind the movement, he goes on to define what smart manufacturing looks in a factory, and how it could enhance automation strategies and transform future aerospace factories.

Why aerospace factories need change

As mentioned in the previous episode, A&D manufacturers will need to address key challenges in their push to increase production volumes, namely in the complexity and modularity of new aircraft. Depending on the function, drones or uncrewed aircraft can integrate incredibly complex internal systems to take on complicated missions. Meanwhile, if a particular airframe is designed to take on a variety of missions, those systems will be different between each aircraft.

In many aerospace factories, the hard tools used to manufacture components are custom built for the aircraft they are producing for, essentially designed to help develop only one type of aircraft. These kinds of factories would become less optimal as new aircraft becomes more modular, unable to produce at desired levels if they must be reconfigured for every new variant that comes down the assembly line. Therefore, aerospace factories would need to become more flexible.

Making factories smarter and automated

According to Todd, the solution to this issue is investing more into smart manufacturing technologies. By his own definition, a “smart” factory—in comparison to factories reliant on manual labor—utilizes data analytics, and automation to optimizes its production processes and operate at higher levels of efficiency.

Data lies at the lifeblood of smart manufacturing. Companies can utilize IoT sensors to monitor everything from the movement of materials to production line robotics and pull data from them in real-time for analysis. This data can then be analyzed, whether by human engineers or even artificial intelligence, to identify any areas that can be targeted for correction or improvement, such as an assembly line that produced 20 percent less throughput than the previous week. This enables changes to be made to production lines with better insights from real-time data, decreasing the risk of errors and optimizing factory processes.

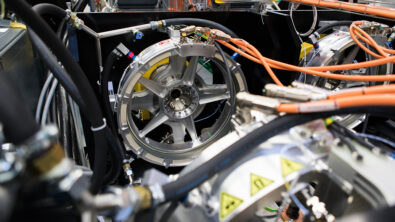

Automation is the other core characteristic of smart manufacturing. It can extend across every aspect of a factory, from the software side, such as the exchange of data, to the hardware side, such as robotic assembly lines and motion control. Automation is especially applicable to routine repetitive tasks that can cause repetitive stress injuries to human workers, such as aligning and riveting composite skins onto an aircraft. Drones and uncrewed aircraft are taking on more and more complex tasks, and the same is going on for factory automation.

Manufacturing for future aircraft

Todd touched on what aerospace factories could look like in the coming years with the implementation of smart manufacturing technologies, and the increasing use of data lies at the center. Everything in a factory can be measured and optimized by data analytics, while automation can help produce aircraft at the numbers desired by companies. Furthermore, combining data and automation can lead to more adaptive and reconfigurable tools and processes, enabling flexible factories that can fit the modularity of new aircraft.

Integrating smart manufacturing technology in aerospace has the potential to not only transform factories, but also the A&D industry as a whole by unleashing new, exciting of aircraft at numbers never seen before.

Stay tuned for upcoming episodes of Talking Aerospace Today that explore even more facets on smart technology and automation in A&D manufacturing.

Siemens Digital Industries Software helps organizations of all sizes digitally transform using software, hardware and services from the Siemens Xcelerator business platform. Siemens’ software and the comprehensive digital twin enable companies to optimize their design, engineering and manufacturing processes to turn today’s ideas into the sustainable products of the future. From chips to entire systems, from product to process, across all industries. Siemens Digital Industries Software – Accelerating transformation.